SSR Roots blower for pneumatic conveying

Pneumatic conveying is to use the air (or gas) flowing in the pipeline to fluidize the materials for conveying granular materials. It is a common method for conveying dust in dust removal engineering. In the process of transportation, there is a state of gas-solid two-phase flow in the pipeline. In the two flows, the ratio of the amount of material transported per unit time to the amount of air consumed is called “material gas ratio”, also known as “solid gas ratio” pressure system, which is divided into a low-pressure pressure system powered by a fan and a high-pressure pressure system powered by compressed air.

The high-pressure compressed air system uses the compressed air as the power, and the compressed air enters the feeder (sender) through the oil-water separator and the air storage tank to compress the materials. Pneumatic conveyor can carry out horizontal, inclined and vertical transportation, and can also form a space transmission line, which is generally fixed. The conveyor has large conveying capacity and long haul distance. It can also complete several process operations in the conveying process at the same time, so it is widely used. It can be transported by a single set, or by multiple sets or by other conveying equipment to form a horizontal or inclined conveying system, so as to meet the needs of different operation lines.

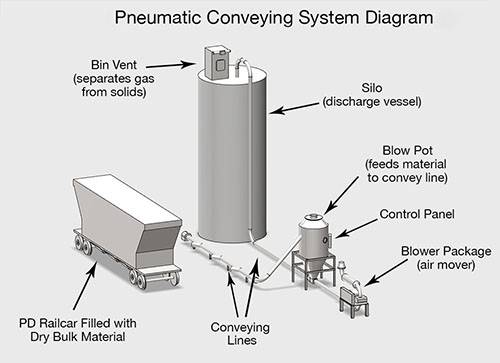

The flow of pneumatic conveying system is as follows:

Roots blower plays an important role in pneumatic conveying, and the air source equipment is the most important equipment in the pneumatic conveying system. The delivery air volume and pressure provided by the utility model can effectively guarantee the effectiveness and reliability of the system. Due to different pneumatic conveying methods, places of use, conveying distance and required conveying capacity, as well as the physical properties of the materials to be conveyed, there are many types of compressors for the air source equipment of the pneumatic conveying system that can be selected, including air compressor, roots blower, roots vacuum pump, centrifugal fan, etc.

Roots blower for pneumatic conveying structural features :

1. Low noise. The inlet and outlet of the fan adopt the spiral shape, so that the air inlet and exhaust process can be cut in sequence according to the direction of the spiral line, so as to avoid the pulsating noise and vibration in the instant when the old fan exhaust fan exhaust. This series of fans adopts a composite muffler with negative reactance, which further reduces the noise.

2. Heat insulation efficiency and volume efficiency are high, so energy saving. The fan rotor adopts advanced compound curve, which makes the engagement more reasonable and increases the volume efficiency.

3. The vibration is small. Although the rotor has been precisely machined, it has become a balanced state. However, high-precision dynamic balancing equipment is still used for balancing. Therefore, the fan operates almost without vibration.

4. The use of high-precision, high hardness synchronous gear not only prolongs the life of the fan, but also effectively reduces the noise.

5. This series of fan adopts bearings imported from Japan or Germany, rubber belts imported from Korea or Taiwan, which makes the product quality more reliable.

6. The output air is clean, free of any oil and dust. The sealing structure of the fan is reasonable, so that the oil cannot enter the shell, so the air is clean.

pneumatic conveying Roots blower application scope:

Pneumatic conveying roots blower is widely used in petroleum, chemical, metallurgy, food, building materials and other departments. In recent years, pneumatic conveying roots blower has been widely used in coal ash, chemical powder, granular material, fine chemical raw materials, cement, raw grain and other conveying projects in thermal power plants. It has many advantages such as low energy consumption, high degree of automation, long-term continuous operation, no environmental pollution and so on. It is an advanced technology most suitable for bulk conveying. The pneumatic conveying system equipment mainly includes roots blower, compressor, rotary feeder, reversing valve, slide valve, cyclone separator, instrument, etc.

Roots blower is widely used in grain, feed, cement, chemical industry, smelting and other industries because of its simple structure, flexible operation, good continuity, high efficiency and low cost. In the pneumatic conveying of grain, we compare roots blower with centrifugal blower, which is more advantageous.

In the pneumatic conveying of centrifugal fan, the gas flow fluctuates a lot, and it is easy to appear small blockage, which will cause the fan flow to decrease greatly. This will result in a larger material gas ratio. The blockage is aggravated, which affects the normal use of the fan.

When roots blower is applied to pneumatic conveying, the ideal condition of pneumatic equipment is that the gas flow provided by the equipment fluctuates little. Therefore, the roots blower with constant flow meets the requirements of this characteristic of pneumatic conveying.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)