Vacuum pump in freeze drying process

Vacuum control is very important in freeze-drying process. Personally, whether the vacuum control is stable and accurate is one of the most important indicators to distinguish whether the freeze dryer is “good”. Temperature control is obviously much easier than vacuum control.

To discuss with me the problems encountered in the freeze-drying process users, many are also headache occasional vacuum runaway. Is it equipment? Or is it a process problem? This is also a big topic.

Because everyone knows that vacuum control in freeze-drying process is very important. So many users who have just come into contact with freeze-drying will be very interested in the vacuum pump equipped with the freeze-dryer.

But in the actual freeze-drying process, the biggest vacuum pump is the cold trap of the freeze-dryer. The cold trap will remove all pressure rises caused by water vapor sublimation.

Vacuum pump is responsible for extracting: upstream vacuum control seepage, cavity leakage, gas products, these three parts, non-condensable gas.

Because there are still many interested and questionable users of vacuum pumps, so the next part will give a brief introduction to the mechanical components of vacuum pumps.

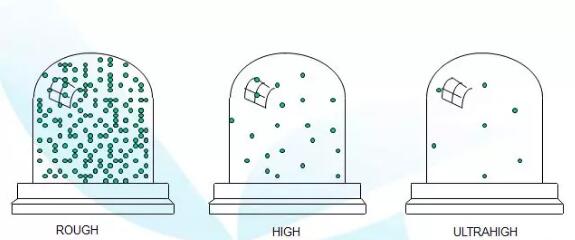

Vacuum level

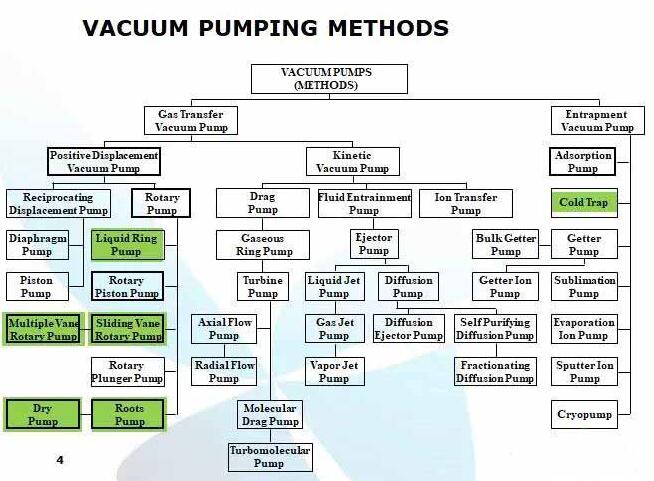

Various types of vacuum pumps

The green labeled pump is used in the freeze-drying process. It should be noted that the “cold trap” (usually liquid nitrogen cold trap) and condensor cold traps in the rightmost column. It’s also classified in pumps.

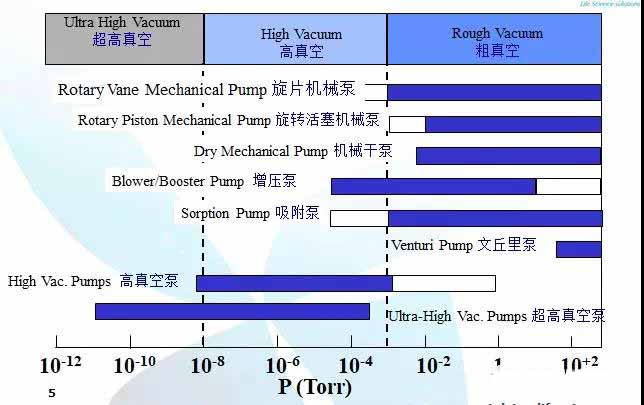

Different vacuum pumps have different working ranges

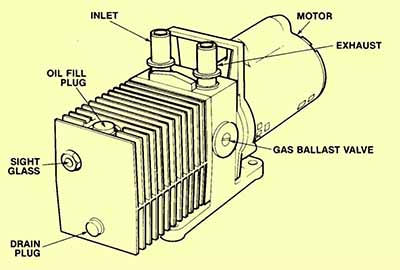

Chinese freeze dryer, we use the most rotary vane pump

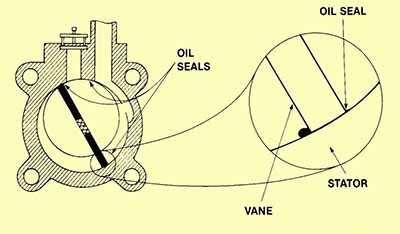

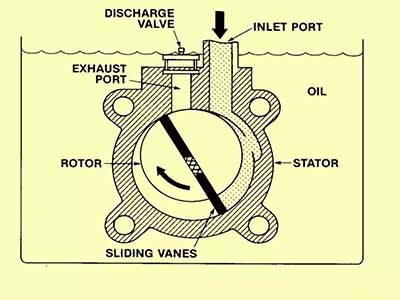

Rotary vane pump is what we usually call oil pump, where oil plays the role of sealing and lubrication.

Solvents are not completely captured by cold traps, entering pumps, or oil used at high temperatures for too long, will lead to a decline in the quality of oil.

The quality of oil decreases and the sealing can not be completed well, which will result in the vacuum can not reach a very low value.

The quality of oil decreases, it can not be well lubricated, and the friction of stator and rotor in the pump increases, which will cause permanent mechanical damage.

Therefore, regular inspection and replacement of vacuum pump oil is one of the important contents of freeze dryer maintenance.

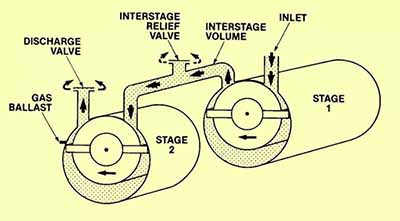

In addition, industrial freeze-drying will also have the front pump and dry pump, as well as water ring pump.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)