steam jet pump principle and fault analysis

steam jet pump principle

Steam jet vacuum pump is a kind of vacuum equipment with simple structure and stable performance. With the development of science and technology, its structural design is more and more suitable for the development of industry. Next, it mainly introduces the working principle and structure diagram of the steam jet vacuum pump.

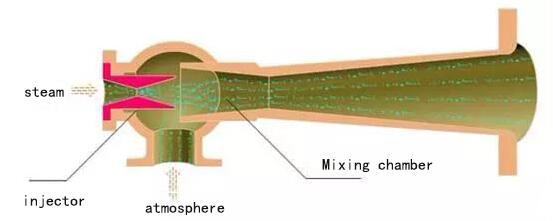

The steam jet vacuum pump is a vacuum pump equipment with a certain pressure. The steam flows through the nozzle to reduce pressure and increase speed. The potential energy of the steam is converted into kinetic energy and injected into the mixing chamber at supersonic speed. The steam is mixed with the pumped medium for energy exchange. The mixed gas enters the diffuser, decelerates and pressurizes, and the dynamic flow is converted into pressure energy. In order to reduce the pumping load of the later stage pump, condensation is configured Through convection of two kinds of medium with certain temperature difference, heat exchange is carried out to condense high-temperature medium.

The working principle is as follows:

Although the structure of the steam jet pump is simple, the operation wear is small, the material requirement is low, and the maintenance amount is small. But the requirement of working steam is high, and the amount of steam used is large.

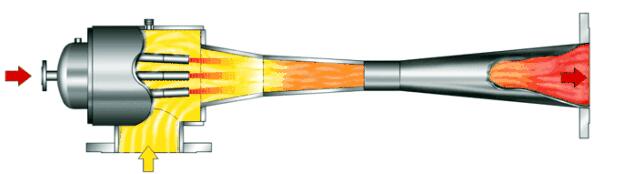

The internal components of jet vacuum pump are mainly composed of Laval nozzle and diffuser. The structure of single-stage steam jet pump is shown in the figure, and the structure of other stages is basically the same. Its working process can be divided into three stages: adiabatic expansion stage, mixing stage and compression stage.

1. In the adiabatic expansion stage, after the working steam passes through the scaling nozzle, the pressure can be converted into the velocity energy, and enters the diffuser at a very high speed. At the same time, the pressure of the working steam drops at the nozzle outlet, forming a vacuum to draw in the extracted gas.

2. In the mixing stage, the extracted gas enters the diffuser. In the diffuser, the steam collides and mixes with the extracted gas to exchange energy, and then to the throat of the diffuser, the two gases reach the same speed.

3. In the compression stage, after passing through the throat of the diffuser, the mixture speed decreases and the pressure rises further. At the outlet of the diffuser, the pressure reaches the atmospheric pressure or the inlet pressure of the later stage injector, and the extracted gas is discharged.

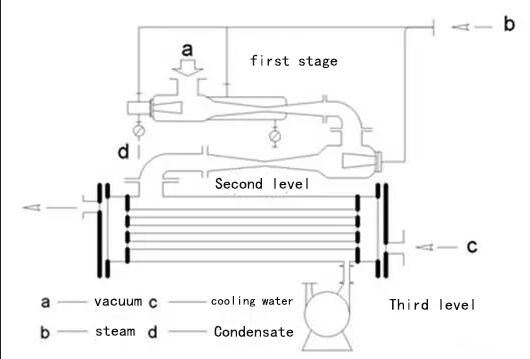

Structure diagram of the unit:

1. The first stage steam jet vacuum pump is connected to the production equipment.

2. The second stage steam jet vacuum pump continues to compress the above working medium, and then the discharged gas is led to the tube condenser for condensation.

steam jet pump common faults

1. Nozzle clogging: there are large particles in the pipeline that block the nozzle, causing vacuum failure;

2. Nozzle wear: after nozzle wear, the speed of steam entering the vacuum pump slows down, which affects the vacuum effect.

The working principle of the steam jet vacuum pump is relatively simple. Users can choose the products they need from the understanding of its working principle. Producers can improve the shortcomings of the products and improve the competitiveness of the products from its working principle.

In general, with the continuous improvement of China’s industrial level, it is necessary to improve the competitiveness of products and market share. After years of development, the steam jet vacuum pump has a very solid foundation. I believe that with the increasing market demand, the steam jet vacuum pump will have a more brilliant future.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)