steam jet vacuum pump knowledge

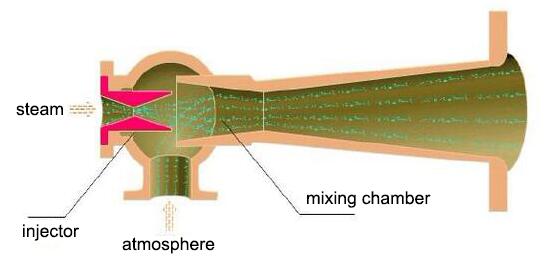

steam jet vacuum pump works at a certain pressure. The steam passes through the Laval nozzle and is injected into the mixing chamber at supersonic speed (the potential energy of the steam is converted into kinetic energy) and then mixed with the medium to be pumped for energy exchange. The mixed gas enters the diffuser and decelerates and pressurizes (the power is converted into pressure energy). In order to reduce the pumping load of the later stage pump, a condenser is equipped There is a certain temperature difference between the two media convection, heat exchange, to achieve the purpose of condensing high-temperature media, discharged to atmospheric pressure. (see the figure below for the principle)

Steam jet vacuum pump operation method:

1. Starting sequence

1) Close all reactor shut-off valves and gate valves.

2) The steam pipe is completely blowdown and drained. The exhaust gas is discharged all the time to supply saturated steam. The blowdown valve is slightly opened.

3) Open the water ring pump, open the water valve of the supply pump, and open the stop valve in the vacuum main pipe to reach about 93 and 9 mbar.

4) Start the two-stage steam jet vacuum pump, the minimum input steam pressure in front of the nozzle shall not be lower than 3 bar or 5 bar, and the maximum input steam pressure shall not be higher than 5 bar.

5) Start the first stage steam jet vacuum pump, and the steam pressure in front of the nozzle shall not be lower than 3 or 5 bar.

6) After all jet pumps are turned on, adjust the inlet valve of condenser to make its discharge water temperature not exceed 36 ℃.

2. Shutdown sequence

1) Close the vacuum master valve.

2) Close the steam valve of the first stage jet pump.

3) Close the steam valve and main steam valve of the second stage jet pump.

4) Stop the pump by venting and close all water supply valves.

Steam jet vacuum pump installation:

1. The steam jet vacuum pump can be installed outdoors. In case of shutdown or freezing weather, the whole unit can drain water quickly, because the internal connecting pipe has been installed for fast drainage.

2. The pump must have enough static pressure, and the stuffing box of the pump must have water seal. An intermittent pump or check valve is installed in the discharge pipe to prevent the return of air. In order to effectively balance the pressure difference between the condensers, there must be a suitable long circuit in the pipeline closed circuit. It is better to install a drain pipe at the lowest position of each loop pipe, which can also be used as the water outlet for cleaning the condenser.

3. When installing the steam pipe, attention must be paid to make the steam sent to the nozzle as dry as possible, and there is insulation between the steam separator and the jet pump. The shorter the steam pipe is, the better. The separator should be kept dry for a long time. Therefore, the steam pipe connected to the jet pump must be connected with warm steam from the upper end of the main steam pipe, which not only corrodes the nozzle and spreads prematurely, but also seriously affects the function of the small nozzle mouth.

Due to the requirement of high vacuum and especially the small nozzle diameter in the pump, it is necessary to check whether the air pipe installed between the steam filter and the steam nozzle in the jet pump is clean. The steam jet pump is equipped with a so-called small steam inlet box, which can easily remove the nozzle and intuitively check the nozzle path with a probe. The steam washer should not be placed eccentrically, so as not to affect the free flow sectional area of steam.

Steam jet vacuum pump maintenance:

1. The packing should be pressed regularly. If the packing can not guarantee the required sealing due to wear, it should be replaced with new packing. The packing should not be pressed too tightly. The normally compacted packing is allowed to leak water in drops, but the amount should not be too much. The oil impregnated asbestos rope should be used as the packing.

2. However, the measured temperature should not be greater than 70 ℃, and 2 / 3 of the whole space in the bearing chamber should be filled with grease. The bearing in normal operation should be filled with oil 3-4 times a year, and the bearing should be cleaned at least once a year, and all lubricating oil should be replaced.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)