The Difference Between Laser Cladding and Conventional Electroplating

Both laser cladding and conventional electroplating aim to improve the surface properties of materials (such as wear resistance and corrosion resistance), but they differ fundamentally in their principles, technological levels, performance effects, and environmental impact.

We can use an analogy to quickly understand this: Conventional electroplating: like painting or applying a thin film to a piece of iron. The film and the substrate are physically or simply chemically bonded.

Laser cladding: like using advanced welding techniques to completely fuse a piece of special stainless steel to the surface of the iron. The two melt at high temperatures, forming a metallurgically bonded “alloy layer.”

The EVP screw pump now incorporates this technology, using laser cladding of 1mm C276 onto the pump body and side covers, making it better suited for use in strong acid industries and offering superior corrosion resistance compared to ordinary electroplating. The following models are compatible:

LG70 (EDSE70)

LGB110 (EDSV70)

LG150 (EDSE150)

LGB220 (EDSV70)

LGB300 (EDSV70)

Laser-clad C276 Hastelloy screw pumps offer superior corrosion resistance, high-temperature resistance, and resistance to pitting/crevice corrosion. They are suitable for various high-concentration, high-temperature strong acid conditions, and are applicable to the following industries and scenarios:

1.Hydrometallurgical Industry: This industry frequently uses high-temperature, high-concentration sulfuric acid, hydrochloric acid, nitric acid, or mixed acids for mineral leaching (such as the extraction of copper, nickel, and cobalt). The medium may also contain chloride ions, fluoride ions, and solid slag particles. Laser-clad C276 screw pumps can resist strong acid corrosion and withstand the abrasion of the slurry, making them suitable for leaching tank slurry transportation, acid circulation, and tailings acidic wastewater transfer.

2.High-end Chemical Synthesis Industry: In the production of fine chemicals and specialty chemicals, high-temperature concentrated nitric acid, fuming sulfuric acid, chlorosulfonic acid, and other strong oxidizing acids, or hydrochloric acid-hydrofluoric acid mixed acid systems, are used. Ordinary fluoroplastic pumps lack sufficient temperature resistance, while the corrosion resistance and high-temperature resistance (up to 600℃ and above) of C276 alloy meet the transportation requirements of such harsh media, such as the transportation of acid solutions in nitration reactions and the circulation of media in sulfonation processes.

3.Nuclear Chemical and Special Acid-Alkali Treatment Industries: The treatment of radioactive acidic waste liquids (containing nitric acid, hydrochloric acid, and radioactive ions) in the nuclear chemical industry places extremely high demands on the corrosion resistance and stability of pumps. The characteristic of C276 alloy being unaffected by chloride ion corrosion can prevent pump failure due to pitting corrosion, making it suitable for the transfer and treatment of radioactive acidic waste liquids.

4.Petrochemical and Refining Industries: Acidic water stripping and hydrorefining processes in oil refineries generate acidic media containing hydrogen sulfide and hydrogen chloride, accompanied by high temperatures. Laser-clad C276 screw pumps can resist corrosion from wet hydrogen sulfide and erosion from acidic media, and are used in scenarios such as acidic water transportation and acid circulation in desulfurization systems.

5.In the electroplating and electronic-grade pickling industries, high-end electroplating processes (such as electroplating of aerospace components) and electronic wafer pickling processes use high-purity hydrochloric acid, sulfuric acid, or mixed acids, requiring high purity of the medium and avoiding metal ion contamination. The corrosion resistance of C276 alloy can ensure the purity of the acid solution, while also being suitable for the acid circulation and wastewater discharge requirements of the pickling tank.

The following is a detailed comparison from various dimensions:

| Comparison Dimensions | Laser Cladding Technology | Conventional Electroplating |

| Core Technology Principles | High-energy metallurgical bonding.

A high-energy laser beam is used to simultaneously melt the substrate surface and the added alloy powder (or wire), and after rapid solidification, a new alloy layer is formed that is metallurgically bonded to the substrate. |

Electrochemical deposition.

The workpiece is immersed in an electrolyte solution, and an electric current is applied to reduce and deposit metal ions on the workpiece (cathode) surface, forming a metal or alloy coating. This is a combination of physical and chemical adsorption. |

| Bond Strength | Extremely high (metallurgical bonding). The coating and the substrate material are fused together, the interface is blurred, and the bonding strength can usually reach more than 70% of the substrate material itself, making it difficult to peel off. | Low (mechanical/weak chemical bonding). The coating adheres to the substrate surface, and the bonding strength mainly depends on intermolecular forces and mechanical interlocking. It is prone to peeling and flaking under high stress. |

| Coating Thickness | It is usually quite thick, generally between 0.2mm and 3.0mm or even thicker, and can be flexibly adjusted as needed. | They are usually very thin, typically ranging from a few micrometers to tens of micrometers (0.001mm – 0.05mm), making it difficult to plate thick and prone to defects. |

| Impact on Substrate | The heat-affected zone is small but exists. Rapid heating and cooling result in minimal thermal deformation, but the surface of the substrate undergoes a miniature “heat treatment”. | It has virtually no thermal effect. When carried out at room temperature or lower temperatures, it does not alter the metallographic structure and properties of the matrix material. |

| Coating Material Flexibility | Extremely high. Various metal alloy powders (nickel-based, cobalt-based, iron-based, tungsten carbide composites, etc.), and even ceramic materials can be used to achieve functional designs. | Limited. Mainly electrochemically depositable metals and their alloys, such as chromium, nickel, zinc, copper, gold, and silver, the types are relatively limited. |

| Coating Performance | Superior performance. The coating is dense and non-porous, providing high-performance properties such as wear resistance, corrosion resistance, high-temperature resistance, and oxidation resistance as needed.。 | Performance is generally average. The coating may exhibit issues such as microporosity and hydrogen embrittlement. Its wear resistance is typically inferior to cladding layers, although some coatings (such as hard chrome) offer relatively good wear and corrosion resistance.。 |

| Environmental friendliness | Relatively environmentally friendly. The process is primarily physical, using metal powder, and produces no toxic waste liquid. Dust and fumes may be generated, but they are easy to collect and dispose of. | The pollution is severe. Electroplating solutions often contain strong acids, strong alkalis, and highly toxic substances such as cyanide and hexavalent chromium, generating large amounts of difficult-to-treat wastewater, waste residue, and exhaust gas. |

| Cost and Efficiency | While the cost per application is high, the overall cost-effectiveness may be high. The equipment is expensive (laser) and has high energy consumption, but it has high material utilization and long coating life, making it suitable for the repair and reinforcement of critical components. | The cost per application is low, but the overall cost may be high. The equipment investment is relatively small, but the costs of consumables (anods, plating solutions) and environmental treatment are extremely high, and the coating life may be relatively short. |

| Main Applications | Advanced Manufacturing and Remanufacturing:

• Manufacturing of high-end components (e.g., wear-resistant coatings for turbine blades)

• Repair and reinforcement of failed parts (e.g., shafts, rolls, molds)

• Rapid prototyping |

General-purpose corrosion protection and decoration:

• Corrosion protection (e.g., zinc plating, nickel plating on steel parts)

• Decorative appearance (e.g., gold plating, chrome plating on jewelry and hardware)

• Improved surface hardness and gloss (e.g., hard chrome plating) |

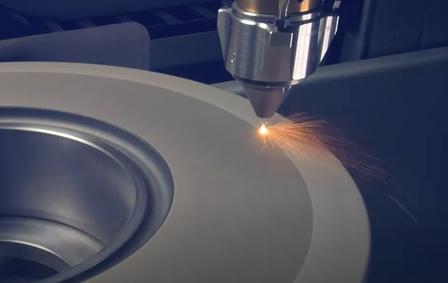

Here are some related images of laser cladding technology:

1.Coaxial powder feeding laser cladding technology: Powder is fed in a ring around the beam or multiple powder beams are fed, and a special protective gas channel is set up, where the powder beam, the beam and the protective gas flow intersect at a point.

2.Off-axis powder feeding laser cladding technology: Alloy powder is fed to the surface of the workpiece through the powder feeding nozzle for pre-positioning. As the cladding head moves relative to the workpiece, a rectangular laser beam scans the pre-positioned alloy powder and melts it to form a molten pool.

3.Ultra-high-speed laser cladding technology: The coupling between the laser beam, powder beam, and inert gas flow is precisely designed so that during operation, part of the laser energy is used to heat the powder beam, while the other part of the laser beam that penetrates the powder beam heats the substrate.

4.High-speed wire laser cladding technology: The metal wire is fed into the laser beam from the side. The laser beam melts the metal wire to form a molten pool. As the cladding head moves relative to the workpiece, a cladding layer is formed.