turbo molecular pump of working principle

Turbomolecular pump of pumping principle

There are two necessary conditions for molecular pump to transport gas

1) Turbomolecular pump must work in molecular flow state. Because when the pressure of the gas contained in a certain volume of container is reduced, the average free path of gas molecules will increase accordingly. Under normal pressure, the average free path of air molecule is only 0.06 μ m, that is to say, as long as a gas molecule moves 0.06 μ m in space, it may collide with the second gas molecule. The average free path is 4.4 mm. If the average free path is larger than the distance between the vessel walls, the collision probability between the gas molecules and the vessel wall will be greater than that between the gas molecules. In the range of molecular flow, the average free path length of gas molecules is much larger than the distance between the blades of molecular pump. When the wall is composed of stationary stator blades and moving rotor blades, more gas molecules will shoot at the rotor and stator blades, which lays the foundation for the formation of directional movement of gas molecules.

2) The rotor blade of molecular pump must have a linear velocity similar to that of gas molecule. With such a high velocity, the gas molecules can change the random scattering characteristics and make directional movement after colliding with moving blades. The higher the rotational speed of molecular pump is, the more favorable it is to increase the pumping speed of molecular pump. Practice shows that the higher the velocity of gas molecules with different molecular weights, the more difficult it is to pump them out.

For example: the content of H2 is very high in the air, but it is difficult for the molecular pump to pump H2 because of its high speed (the most probable speed is 1557m / s). Through the analysis of the residual gas in the limiting vacuum, it is found that the proportion of hydrogen can reach 85%, while the molecular weight of oil is large, and the proportion of oil molecules with slow motion speed is almost zero. This is the molecular pump oil vapor and other high molecular weight gas compression ratio is very high, pumping effect is good reason.

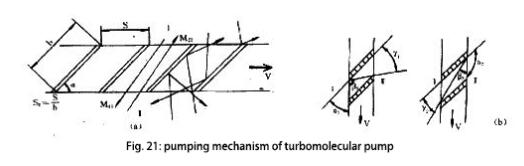

In this paper, a blade of turbomolecular pump is taken as an example to illustrate its pumping principle. Suppose that an axial-flow single leaf train moves with velocity V in the range of molecular flow, as shown in Fig. 1.

Fig. 1: pumping mechanism of turbomolecular pump

Let I side be the suction side and the II side as the exhaust side. The gas molecules moving from the I side to the II side can be divided into the following situations: a part of the gas molecules collide with the end of the blade and return to the I side, some of the gas molecules directly reach the II side through the blade slot, and a part of the gas molecules collide with the blade wall in the blade groove, and the collision results will make part of the gas molecules reach the II side and the other part of the gas molecules return to the I side. Similarly, for side II, some gas molecules directly arrive at side I from side II, and some molecules return to side II or reach side I after colliding with blades. As shown in Fig. 1 (b), when the gas molecules on the I side collide with the blade, those with the reflection direction in the angle of α 1 will return to the side I, while the gas molecules with the reflection direction within the angle β 1 will finally enter the side II or scatter back to the side I, and the gas molecules that hit and re reflect in the angle γ 1 will enter the side II; Similarly, all the gas molecules incident on the blade from side II will still return to the I side if they are re reflected in angle α 2. The gas molecules re reflected in the angle γ 2 will scatter to the I side, while the gas molecules re reflected in the angle β 2 will either scatter to the I side or return to the II side. From the size relationship of α 1, α 2, β 1, β 2, γ 1, γ 2, it can be seen that the probability of gas molecules from side I to side II is greater than that of gas molecules from side II to side I. The greater the velocity V of blade, the more obvious the effect is. Thus, the purpose of pump pumping is realized. The blade inclination angle α, blade chord length B, pitch chord ratio S0 and linear velocity v all have influence on the suction effect of blade row.

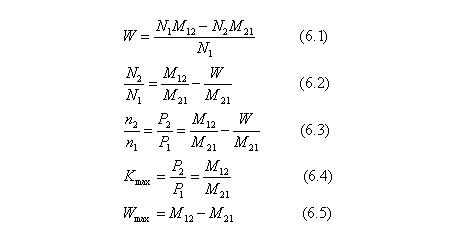

Let N1 and N2 denote the flow rate of gas molecules incident to the blade from side I and side I respectively. W is used to indicate the arrival from I side

Figure. 2: calculation formula for pumping mechanism of turbomolecular pump

The ratio of the net gas molecular flow rate on the side Ⅱ to the incident gas molecular flow rate, W is called the he’s coefficient, then formula (6.1) or formula (6.2) can be used

If the temperature on both sides of the blade is equal and the distribution function of gas molecular velocity is the same, then N2 / N1 is the density ratio N2 / N1 or the compression ratio P2 / P1. Namely: (6.3)

When the net gas flow through the blade row is zero, the maximum compression ratio (6.4) can be obtained

When the compression ratio is 1 (P2 = P1), he’s coefficient is the largest, i.e. (6.5)

The actual turbomolecular pump is composed of multi-stage cascade, that is, push vane, fixed blade, moving blade Alternating in order. The total compression ratio of the pump is determined by the number of stages of the cascade. In the design of turbomolecular pump, the combination of multi-stage blade row should be optimized. Generally, the blade shape and size with larger pumping speed should be selected near the pump inlet side, and its compression ratio can be relatively small. After several stages of compression, the gas pressure increases and the pumping speed decreases, so the blade shape with high compression ratio and low pumping speed should be selected. This design can make the pumping performance of the whole pump get the ideal results of high pumping speed, high compression ratio and few stages.

There are many methods to calculate the transfer probabilities of molecular pumps, such as M12 and M21. For example: integral equation method, angle coefficient method, Monte Carlo method, matrix method, engineering approximate calculation method and so on.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)