vacuum pump classification

Vacuum pump is a kind of rotary variable volume vacuum pump, which needs the cooperation of the front pump. It can be used in a wide pressure range with a larger pumping speed. It is insensitive to dust and water vapor in the extracted gas. It is widely used in metallurgy, chemical industry, food, electronic coating and other industries. The machine that sucks the gas out of the equipment so that the pressure in the equipment is lower than one atmospheric pressure is called a vacuum pump. In fact, the vacuum pump is a kind of gas conveying machine, which conveys gas from the environment below one atmosphere pressure to the atmosphere or the same environment as the atmospheric pressure. Flow rate and vacuum degree are the two most important factors for choosing the suitable vacuum product. Flow rate is the key factor for determining the size of the product. The higher the flow requirement, the larger the volume of the product, the higher the power of the motor required. Vacuum degree is the key factor for deciding the structure of the product. Vacuum degree is the reading of surface pressure and absolute pressure. The types of vacuum pumps are water ring vacuum pump and direct vacuum pump.

vacuum pump in chemical industry:

Vacuum pumps are often used to create a certain degree of vacuum to achieve the process operation. For example, under the suction of vacuum pump, the filtration speed of solution is accelerated; when separating liquid mixture, the distillation temperature can be reduced to avoid the coking and decomposition phenomena that may occur in high temperature distillation; the temperature of dry solid material is reduced and the speed is accelerated; the heat pipe of heat pipe heat exchanger is pumped into vacuum and injected distilled water, which greatly accelerates the heat transfer rate, and so on. Electronics and defense industries often need higher vacuum.

With the continuous development of vacuum technology, people can obtain a wider range of vacuum, from absolute pressure of 1.0133*l05Pa to 133.32*10-‘5Pa. Therefore, the vacuum region is divided as follows:

Crude vacuum: pressure range 101.3 *l03-1.3332 *l03Pa (10-760 mmHg)

Low Vacuum: Pressure range is 1.3332*l03~133.2*lO-zPa (10-2~lOmmHg)

Medium Vacuum: Pressure range 133.2 x 10-z-133.2 x l0-7Pa (10-4-10-2mmHg)

High vacuum: pressure range is 133.2 x 10-4-133.2 x l0-7Pa (10’7-10-4mmHg)

Ultra-high vacuum: pressure range below 133.2 *l0-7Pa (below l0-7mmHg)

In chemical production, generally in the rough, low vacuum area operation can meet the production requirements.

The types of vacuum pumps can be divided into dry vacuum pumps and wet vacuum pumps according to their working conditions. The vacuum degree of the vacuum pump can reach 96 y/-99.9}/, and the vacuum degree of the wet vacuum pump can extract the mixture of gas and liquid, which can reach 80%-85%.

The main performances of vacuum pump include pumping rate and limit vacuum.

1. Pumping rate

The volume of the suction gas per unit time is called the suction rate, which is expressed in symbol S and is 113/h or d/s. It indicates the suction capacity of the vacuum pump.

2. Limit vacuum

Limit vacuum, also known as residual pressure, refers to the lowest absolute pressure that a vacuum pump can achieve. It is expressed by symbolic sound and expressed in units of Pa.

3. Vacuum degree and percentage of vacuum degree

Vacuum is the difference between atmospheric pressure and absolute pressure in a vacuum system. It is expressed as a symbol user in Pa. That is p. The absolute pressure in the p-vacuum system of -101.3 x l03_p (Pa) formula is Pa.

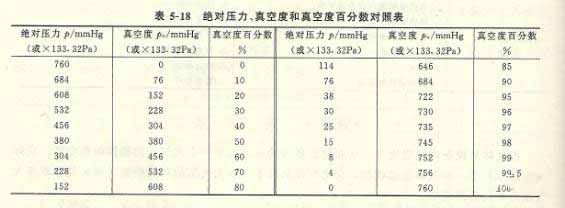

The percentage of vacuum degree is the ratio of vacuum degree to atmospheric pressure, i.e. P. The comparison of the percentage of absolute pressure, vacuum degree and vacuum degree on the (%) side I {magnificent x 100% is listed in Table 5-18. Table S-18 Absolute Pressure.

Vacuum Percentage Control Table:

From Table 5-18, we can understand the relationship between absolute pressure, vacuum degree and percentage of vacuum degree. For example, the absolute pressure is 152 mmHg and the vacuum is 608 mmHg when the percentage of vacuum degree is 80%. If the limit vacuum of a vacuum pump is known to be 114 *133.32 Pa, the percentage of vacuum degree can be found to be 85%, and the vacuum degree can be reached to 646 *133.32 Pa.

When the vacuum pump is working, it continuously pumps out the gas in the container, which reduces the gas in the container and gradually reduces the pressure. When the gas pressure in the container is lower than a certain minimum, the following situations often occur: the liquid in the container vaporizes; the gas leakage from the high-pressure side of the pump is the same as that from the vacuum pump; and the pressure ratio of the vacuum pump is too high to stop the suction process. At this time, the pressure in the container will not be reduced, so the pressure can not be reduced to absolute vacuum indefinitely. There are many kinds of vacuum pumps, which can be divided into reciprocating vacuum pumps, rotary vacuum pumps, water ring vacuum pumps and water jet vacuum pumps.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)