Vacuum system for aminodiphenylamine

In recent years, the domestic and foreign markets of p – amino-diphenylamine and its derivatives for rubber antiaging agent are in fierce competition. There are problems and shortages in the operation of the vacuum pump in the vacuum distillation process of chemical industry, the selection and economic benefits of the vacuum pump are analyzed and discussed.the vacuum pump used after the vacuum system transformation can achieve the advantages of energy saving, environmental protection, emission reduction, stable production and efficiency. The practical application of vacuum system in p-amino-diphenylamine is the following xiaobian focus to introduce the content, to analyze the working principle of the vacuum system, and choose what kind of vacuum system.

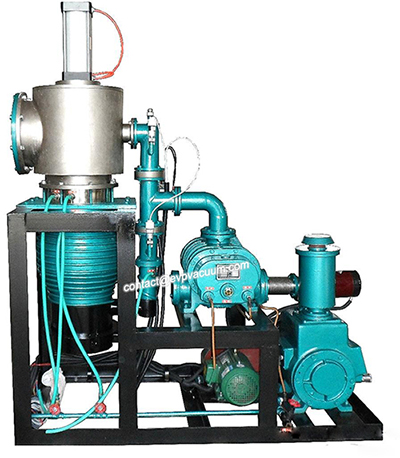

We recommend the use of diffusion pump main pump series roots pump, and then series mechanical pump formed by the vacuum pump system.

P-amino-diphenylamine, also known as amino-diphenylamine, is an important fine chemical intermediates, can be used in rubber additives, dyes, textiles, printing and pharmaceutical industry, mainly used in the production of p-phenylenediamine rubber antiaging agent 4010NA, 4020, 688. As an intermediate of p-phenylenediamine rubber auxiliary agent with excellent performance, the quality and cost of p-aminophenylenediamine directly affect the production and application of 4010NA, 4020 and 688. The purity of the product is above 98%. The reducing solution containing para-aminophenylamine crude product produced in the reduction process is purified by the vacuum distillation process. In the production, the vacuum equipment usually USES the wet vacuum pump, which consumes a lot of energy, is easy to leak, pollutes the environment, and produces the waste water which is difficult to treat.

In order to overcome the disadvantages of the wet vacuum pump, our company provides a vacuum system used in amino-diphenylamine, the vacuum system is high vacuum, stable performance, long life, compact structure, small footprint, simple operation and maintenance, less noise, and without access to water.

How a vacuum system works

The main vacuum pump group of the startup system starts to work until the vacuum degree in the vacuum tank reaches the set upper limit value, the vacuum pump stops running automatically, and the vacuum in the central vacuum system is maintained by the vacuum check valve on the pipeline. If the vacuum degree in the vacuum tank falls below the set lower limit due to the working demand, the standby vacuum pump set will start automatically. The vacuum degree of the vacuum system can maintain a stable vacuum source and meet the requirements of production.

Dehydrating aniline in the process of crude distillation, the vacuum degree is not high. High vacuum degree is needed in the purification of rectification process. Roots vacuum pump is used to obtain vacuum. Two rotary vane vacuum pumps are used in the crude distillation tower respectively, the power is 22kw and 90kw, and the ultimate pressure is below 20kpa. The rectifying tower USES roots vacuum pump, the steam consumption is 1500kg/h, the limit absolute pressure is below 3kpa.

Vacuum system in the practical application of p-amino-diphenylamine, the most important process is vacuum distillation. Vacuum distillation (also called vacuum distillation) is an important method for the separation and purification of compounds, especially for the separation and purification of high boiling point substances and those compounds that have been decomposed, oxidized or polymerized before reaching the boiling point during atmospheric distillation. Vacuum distillation is of particular importance for the separation or purification of liquid organic compounds with higher boiling points or less stable properties.