Double Stage Sliding Vane Rotary Vacuum Pump

With the continuous development of science and technology, the field of machinery requires more efficient and energy-saving. At present, the pumps used have low mechanical efficiency, small flow, large noise, complex structure, etc., such as gear pump, plunger pump, air pump, water ring vacuum pump, etc. The purpose of the technology is to provide a kind of pump machinery with large flow, high efficiency, simple structure, large pressure and wide application range.

The two-stage sliding vane rotary vacuum pump can be used as a liquid pump or a gas pump. It has the characteristics of wide applicability, large displacement, high efficiency, energy saving, high vacuum and large pressure. It can be directly used in daily life, as well as in various fields such as industry, agriculture, mining, oil field, textile, chemical industry, light industry, transportation, wind power, machinery, etc.

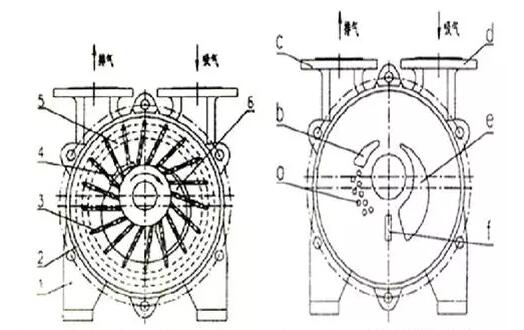

The working principle of two-stage sliding vane rotary vacuum pump is mainly composed of stator, rotor, sliding vane, fixed cover and other parts. The structure is to install the inner rotor in the eccentric part of the stator cavity, so that the gap between the outer circle of the rotor and the inner surface of the stator is very small, and there is a sliding integral rotor blade in the rotor slot. When the rotor rotates, it always slides along the inner wall of the stator. When the rotor rotates in the direction shown in the figure, the volume of space a connected with the suction port increases continuously, space a forms a vacuum, and the gas is continuously pumped into the suction cavity a, which is in the process of suction. The volume of cavity B is decreasing and the pressure is increasing, which is in the process of compression. The volume of space C connected with the exhaust port is further reduced, the pressure of space C is further increased, the compressed gas pushes the exhaust valve, and the gas is continuously stored or discharged to the atmosphere. During the continuous operation of the pump, the process of suction, compression and exhaust is continuously carried out, so as to achieve the purpose of continuous compression or extraction.

The working efficiency of the two-stage sliding vane rotary vacuum pump is continuous suction and compression at the same time every rotation cycle. The suction force generated is vacuum work, and the high pressure generated can work on other equipment. The integral eccentric vane rotary pump produces two times of large displacement every revolution, which can produce twice of working energy compared with other pumps and achieve greater working efficiency. The double stage vane rotary vacuum pump has small volume and high efficiency. It can be applied to the energy storage wind turbine to compress and store air with the integral vane rotary pump. According to the power demand, the integral vane rotary pump can be driven by compressed air Row rotation, as an air motor to drive the generator to generate electricity at a constant voltage and frequency in real time, to implement energy storage power generation to make full use of wind energy resources. Or use pneumatic tools for compressed air to be directly used in production. The whole sliding vane pump has a large pumping force and a fast speed, so it can get a greater vacuum force, especially in the vacuum sewage cleaning, vacuum pumping on the manure truck and other use effects will be better. As an air compressor, it can get more compression force at the outlet, can compress the gas, and can be used in more occasions.

The double stage sliding vane rotary vacuum pump adopts one integral sliding vane or two intersecting integral sliding vanes, which pass through the middle of the rotating shaft. The shell adopts the curved surface structure, which makes the sliding vane slide along the shell to maintain a certain gap. This structure can reduce the vibration force and the wear on the shell. The work loss is less, which can produce greater vacuum degree, faster evacuation speed and more Large compression force and displacement. The curved surface shell of the integral sliding vane pump can be processed by inserting, turning, grinding and other methods on the self-made special rotating disk equipment. A suitable method of shell machining has been developed.

The vacuum pump composed of two-stage sliding vane rotary vacuum pump is composed of two working rooms. The two rooms are connected in series in the same direction and rotate at the same speed. Chamber I is of low vacuum level and chamber II is of high vacuum level. The pumped gas enters chamber II from the air inlet. When the pressure of the gas entering into chamber II is high, the pressure of the gas shrinks and increases rapidly. The compressed gas is not only discharged from the high-level exhaust valve, but also passes through the middle The wall passage enters into chamber I and is compressed in chamber I and discharged from the low-level exhaust valve; when the gas pressure entering chamber II is low, though it is compressed in chamber II, the high-level exhaust valve can not be pushed to discharge. All the gas enters chamber I through the middle wall passage and continues to compress in chamber I and is discharged from the low-level exhaust valve, so that the vacuum limit of the two-level rotary vane vacuum pump reaches a higher level

The two-stage sliding vane rotary vacuum pump is a kind of rotary positive displacement pump, which changes the working volume through the relative movement between the rotor and the pump body, and then increases the energy of the liquid, with a positive displacement property, and its flow does not change with the change of the back pressure. Rotary pump is suitable for transporting heavy oil, crude oil, residual oil, Huai grease, rubber, glass fiber and asphalt with high viscosity of 0.02-100pa. S and temperature below 200 ℃. Toothpaste, cosmetics, paste food, paste, grease, ink, chemical fiber size of any and physical properties, to ensure that the original quality is not affected by the slightest, but also suitable for conveying a variety of corrosive liquid containing solid particles. The preferred choice of rotary pump occasions are: viscous liquid, need to measure occasions, need to self-priming occasions, contain gas occasions, small flow occasions, need to medium soft pump, need to reverse the pump, and high pressure occasions.

Through the technology of two-stage sliding vane rotary vacuum pump, it can be further innovated. The shell curve is the same. The whole sliding vane rotates in the form of eccentricity. The whole sliding vane rotates on its own, making the whole sliding vane move along the shell, keeping a certain gap with the shell all the time. Without wear, there will be no high temperature. It can reduce the driving resistance, improve the working efficiency, and form a new rotating vane Pump.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)