vacuum pump for chemical material dry room

Vacuum technology is more and more widely used in the vacuum evaporation, crystallization, distillation, sublimation, drying, negative pressure concentration, dehydration, chemical reaction absorption and vacuum conveying of materials and other processes in the petroleum, chemical, pharmaceutical and other industries. The application of vacuum technology in various processing processes can save energy and reduce consumption, accelerate reaction speed, improve product quality and increase economic benefits, and gradually form a consensus, However, vacuum technology is a marginal science. China’s vacuum industry developed on the basis of digesting and absorbing the products of the former Soviet Union, the United States, Japan and Germany after liberation. Although the number of vacuum equipment manufacturers in China has mushroomed in recent years, many vacuum pump manufacturers are not clear about how to apply and select their vacuum pumps in different processes (let alone not According to the process parameters provided by users, new product design is carried out), which brings great inconvenience to the selection of users.

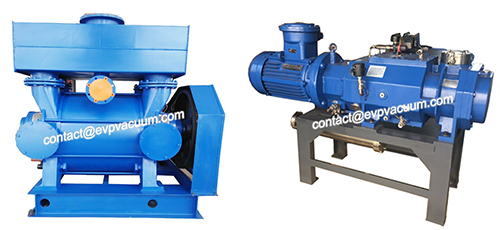

When it comes to the application of vacuum pump, that’s too much, because there are many types of vacuum pump, which are widely used in plastic machinery, brick and tile machinery, low-temperature equipment, papermaking machinery, food machinery, industrial electric furnace, electronic industry, vacuum equipment, petrochemical industry, metallurgy, mining, medicine and ground-based treatment and other fields. Today EVP vacuum pump manufacturers just say chemical drying chamber vacuum pump.

Vacuum drying chamber is used in many scientific and industrial fields to dry thermal materials quickly and effectively. Traditional drying processes can damage thermosensitive materials, such as food, drugs, chemicals or electronic components, or change the performance of their products. The drying process in a vacuum drying chamber can reduce this risk to a lower level. Vacuum drying is one of the effective and mild drying methods. The purpose of this method is to gently dry advanced products containing water or solvent without endangering the material.

For compounds containing flammable solvents, it is particularly recommended to dry them in a vacuum drying chamber, especially because of the oxygen in the air, which often forms an explosive atmosphere during the drying process. This is prevented when drying in a vacuum drying chamber, which can also reduce the risk of scaling or oxidation residues to a greater extent.

In the vacuum drying process, the material to be dried is subjected to a reduced pressure environment, which reduces the boiling point in the drying equipment and facilitates the evaporation of water or capillary transport. Targeted heat and pressure control supply optimizes the drying process. Another positive effect is the low cost of energy, because vacuum makes it possible to dry materials at very low temperatures.

It is often not easy to choose suitable vacuum technology for chemical and pharmaceutical process applications. First of all, the vacuum system must provide the required pump speed under the working pressure to ensure the required vacuum time. Secondly, it can not be sensitive to process gas, so it must meet all requirements when it is used for CIP (in-situ cleaning) cleaning and gas recovery. In addition, stability and economic efficiency play an important role in determining which vacuum technology to use.