Vacuum pump for clay brick vacuum extruder

Required vacuum for industrial standard

As per the latest edition of Chinese Building & Decorative Industrial Standard JC/T343.1-2003, the vacuum should be ≤ -0.092MPa G (93mbar abs) on vacuum extruder. This is very close to international standard.

Pump selection

Which one better, single stage or two stage ?

Two stage vacuum pump was usually regarded as better choice than single stage. This fallacy is resulted by misunderstood by extruder’s manufacturers that two stage pump has more reliable performance than single stage pump. Hence most of extruder manufacturer equips two stage pump for their machine.

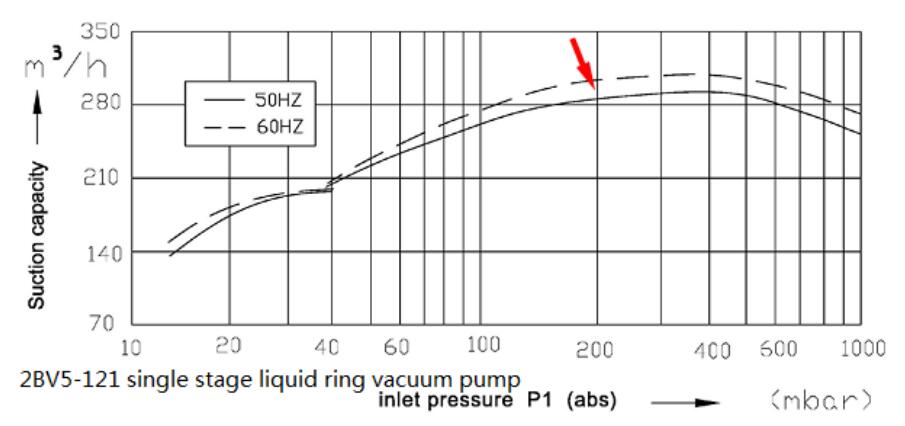

Because the working vacuum on most of extruder pump is -0.08MPa G (213mbar abs) in real application. The single stage pump can totally meet the request as we can see from followed curve.

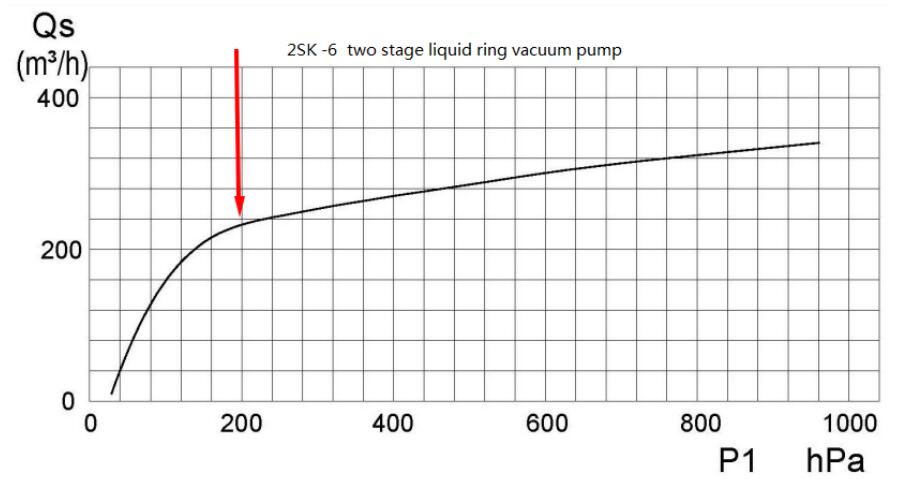

Especially when the old pump on your extruder machine uses the traditional 2SK model, its air flow is limited in high vacuum and performance is very close to the single stage pump, here is the curve of traditional 2SK pump. Its suction capacity drops obviously when pressure lower than 200mbar vacuum.

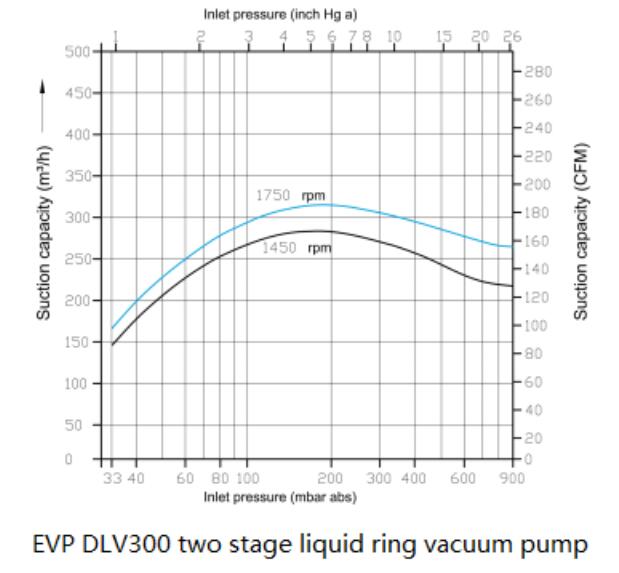

And of course, the two stage liquid ring vacuum pump has advantage on high vacuum if its quality is good, for example EVP DLV type shown as followed curve.

Which pump is more energy-saving ?

In past years, the vacuum extruder had been over powered. Some 450 type extruder equips a 22kw power vacuum pump to make up the design and manufacturing defect of sealing by larger air flow. It leads to waste of energy. Currently, it’s normal that the extruder model less 600 equips 5.5kw vacuum pump. Oil sealed rotary piston vacuum pump is most energy saving. Taking the 5.5Kw H-series piston pump for instance, its air flow reaches 100L/s at -0.085MPa G (163mbar A) vacuum. On consideration of energy saving, the rotary piston comes to be top option. But the cost of oil sealed rotary piston pump is relative high, and it cannot such air with dust or particle. A filter device must be added to prevent pump being broken.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)