Vacuum pump for electrolytic capacitor

Vacuum pump in electrolytic capacitor enterprise of energy saving reform

The vacuum pump is a two-stage roots water ring pump unit, because the efficiency of the water ring pump is low

Vacuum pump status quo

The measured temperature of water ring pump is about 30-40 ℃. The water ring vacuum pump has a power of 11 kw and a nominal maximum pumping speed of 8.33 m3 / min for 15 degree chilled water. The domestic equipment has a virtual standard and the maximum pumping speed is only 80% under the actual chilled water condition, which is about 400 m3 / h. The water ring pump is cooled by an open cooler and supplied with soft water. The scaling problem is not serious. Under the condition of non chilled water, the actual pumping speed is reduced by 20%, about 320m / h. Because the average water temperature is 30 ℃, which is higher than the standard water temperature of 15 ℃, the average suction pressure of water ring pump is 150 mbar, the proportion of water vapor is 50 / 150 = 33%, and the proportion of air extraction is 67%. Therefore, the final air pumping speed of water ring pump is 214m3 / h.

Claw type energy saving transformation

Due to the low vacuum pressure and high water temperature of the original two-stage roots water ring pump unit, the steam extraction ratio of the water ring pump reaches 33%, and the efficiency is obviously low.

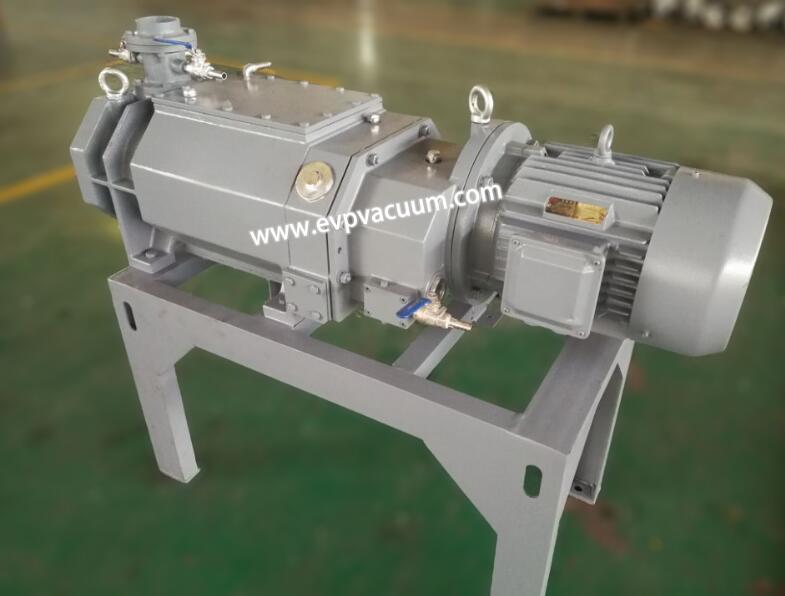

Domestic water ring pump does not use chilled water, but its efficiency is low under the condition of pumping vacuum of 150mbar. The engineer suggested to replace it with oil-free claw pump

In order to prevent the electrolyte from entering the vacuum pump unit, prolong the service life of the unit, reduce the amount of maintenance, and reduce the exhaust emission. It is specially equipped with a deacidification and demisting tank. The tank body is equipped with a liquid level monitoring tube. When there is more electrolyte, the vacuum can be released to discharge the electrolyte from the bottom.

Case study on energy saving transformation of vacuum pump in an electrolytic capacitor enterprise

New oil free claw vacuum pump of advantages

1) High efficiency and energy saving. Claw vacuum pump series, using advanced oil-free rotary compressor technology, develop a new generation of energy-saving products.

2) Claw vacuum pump is air-cooled, saving cooling water system and operation cost.

3) Dry claw vacuum pump, no water in the vacuum pump cavity, avoid unnecessary extraction of water vapor, no work.

4) Dry claw type vacuum pump, there is no water in the vacuum pump cavity, so as to avoid the problem of reducing the pumping capacity of the vacuum pump caused by scale.

5) It’s easy to operate, and it’s cheap to have professional maintenance personnel.

6) The power supply system reduces the load and saves the investment of cable, transformer and switch cabinet.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)