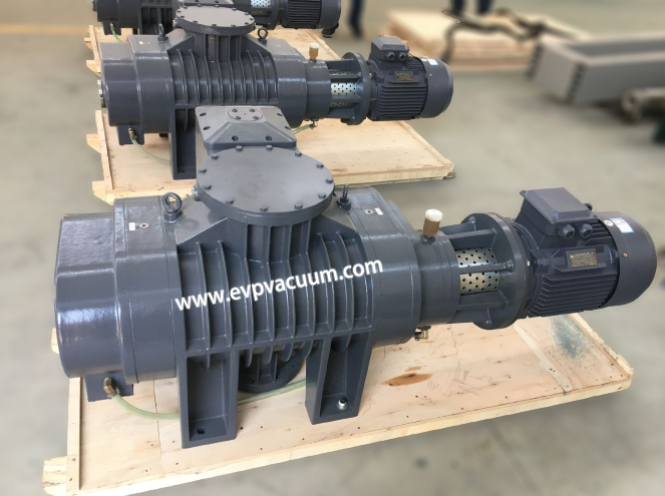

Vacuum pump for field gas boosting

Field gas pressurization is the process of pressurizing low pressure gas from wellhead to high pressure pipeline. Gas pressure at the wellhead, either below atmospheric pressure or at relatively low positive pressure, requires a vacuum pump or a low pressure compressor to pull the gas out and raise it to 15 to 30 PSI above atmospheric pressure. The liquid ring vacuum pump or compressor is used as the first stage to deliver the gas to the second high pressure compressor. A high pressure compressor, usually a rotating screw or reciprocating compressor, carries gas through a pipeline to a gas treatment plant.

Maximum pressure of gas booster pump: 1kPa –160kpa, inlet pressure can be accumulated, gas booster pump flow (cubic meter /min):0.3-290 (according to different needs to choose different flow and pressure) Characteristics of natural gas, biogas booster pump this product is specially designed for natural gas, biogas and other toxic and harmful gases. It can improve the phenomenon of insufficient natural gas pressure, make natural gas combustion more full, more firepower. Due to the negative pressure effect of the pump, it is widely used in all kinds of natural gas, biogas pipeline transportation, can be used in natural gas, biogas combustion pressure is low, low pressure pipeline transportation places. Different from other pumps:

1. Good air tightness: strictly test air tightness from inlet to outlet without air leakage.

2. High flow rate from 0.3 m3 /min to 90 m3 /min. You can choose different models according to your needs.

3. Long life: The gas path and circuit are strictly separated, and the electrical life will not be affected by the gas rich water vapor.

4. Have good sex: Be able to use simple tools and accessories.

5. Explosion-proof motor

6. Pressure flow within a certain range can be adjusted by natural gas, methane gas booster pump working principle: natural gas, methane gas booster pump using two rotor frictionless squeeze each other to form a negative pressure function of the methane from the generator, discharge from the outlet and complete the whole process of high pressure conveying, throughput to complete with all kinds of capacity model, the size of the small adjustment available speed to complete.

Micro-adjustment can be accomplished by regulating valves. The pressure of Roots vacuum pump is accomplished by motor power. We like to call the gas booster pump use manufacturer must get gas booster pump operation instruction (formal turbo booster pump products when they go out of all the attached a file bag, enclosed packing list, certificate of approval, instruction manual, 3 packets of inter alia) to use natural gas booster pump operator perusal, in strict accordance with the turbo booster pump operation instruction within the provisions of the operation/inspection/maintenance gas booster pump, do your best may reduce the booster pump failure or in real time to prevent failure of expanded! For the use of natural gas booster pump fault manufacturers, the solution is no more than according to the severity of the fault to choose:

A Replace the head of the natural gas booster pump of the same model (the motor and the common base do not move), B return to the plant, C site.

The advantages of option A are: the new natural gas booster pump nose installation docking system can be used, and the new gas booster pump has A long period of three guarantees as A guarantee (generally 12-18 months).

Disadvantages are: production/delivery cycle is long, because the natural gas booster pump manufacturers may not have the same type of spot pump head can be timely supply. The cost is relatively high.

The advantage of choice B is that after the natural gas booster pump is repaired, it can be tested in the factory according to the technical parameters of the booster pump nameplate. After passing the test, it can leave the factory, and its quality can be generally guaranteed.

Disadvantage is: because the general need to return to the plant booster pump because of the fault is quite serious, the main parts of the natural gas booster pump damage is serious, the site does not have the conditions to consider back to the plant!

At the same time the factory also generally need to booster pump complete disintegration to check the damage of all parts and then give a plan and quotation, the factory in order to ensure quality will inevitably be forced to use some of the original machine parts included in the replacement! The cycle is also longer (plus the forward/backward time consumption). The cost is second only to the purchase of a new booster pump head (sometimes the cost is even close to the purchase of a new booster head). Accessories and three guarantees period of one year.

The advantage of choice C is: the cycle is the shortest (that is, the need to purchase part of the parts), because it is in the site to disassemble booster pump and then determine the need to replace the parts, so the user can save parts costs as much as possible, the use of the original machine parts can be as much as possible! Some standard parts can also be purchased locally according to the model specifications! Users can more clearly understand the booster pump some parts have been replaced, some did not replace! The cost is relatively low.

Disadvantages are: due to different user conditions (such as lifting, tools, etc.), the reliability of assembly is not the same. Booster pump repair immediately put into use, no conditions for similar in-plant testing work. Accessories and three bags period generally only 3 months. Because a considerable number of natural gas booster pump use manufacturers do not have a special booster pump operation and maintenance personnel, so once the natural gas booster pump failure, self-handling ability is quite limited, can only need external help to solve. So in the market formed a huge capacity of natural gas booster pump accessories and market. The basic working principle of natural gas booster pump is the same, because the manufacturer’s design ideas are different and the development of various types of specifications of natural gas booster pump.

So different booster pump manufacturers production booster pump, the vast majority of spare parts are not interchangeable (that is, calculate the appearance of natural gas booster pump similar, inlet and outlet diameters are exactly the same). The standard parts (such as bearing, oil seal, O-ring, gasket, etc.) used on the natural gas booster pump can be purchased in the market according to the model specifications. Therefore, for the technical personnel who have learned the whole assembly of Roots blower booster pump in the natural gas booster pump manufacturer (at least one year) and engaged in after-sales service work (at least one year),

Generally have the ability to handle and repair common fault Roots booster pump. Booster pump manufacturers or suppliers are generally the part of the after-sales service into the sales department, effectively ensure the product before sales, sales, after-sales unity. Service to improve sales, sales to improve service.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)