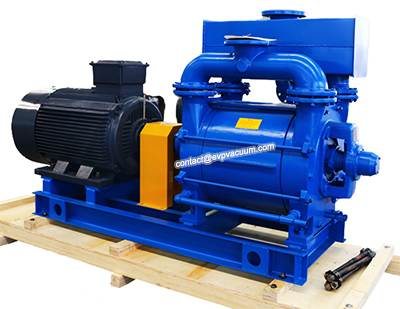

Vacuum pump for metallurgical process

In the process of reasonable selection of vacuum pump, EVP water ring vacuum pump manufacturer thinks that it can be selected according to the working pressure required by specific process and the nature of suction gas. Generally, the working pressure required by the specific process shall be determined first, and the vacuum degree required by vacuum distillation, distillation, sublimation and other processes shall be high (low working pressure), and the vacuum degree required by vacuum evaporation, drying, concentration, crystallization, dehydration, decolorization, chemical reaction absorption, vacuum conveying materials and other processes shall be low (high working pressure).

For vacuum metallurgical equipment, the gas sources during cold furnace pre pumping and hot smelting are as follows:

① The atmosphere in the extracted space (related to the extracted volume),

② Gases released in the process (including generated and introduced gases, related to time, Ju degree, pressure and production process),

③ Air release from surface exposed in vacuum (related to material type, surface area, time, temperature, pressure, etc.),

④ Gas leakage and penetration (related to the air leakage rate of system components, the welding quality of dynamic and static sealing components of equipment and the structural material),

⑤ A volatile gas (related to temperature and pressure) caused by the vapor pressure of a material.

In order to meet the needs of metallurgical process, the vacuum system design of vacuum pump manufacturers is to select appropriate vacuum elements, such as pumps and valves, according to the above-mentioned gas flow, and put forward a reasonable layout plan according to the air extraction process, so as to pump out the gas in the space to be pumped, overcome air bleeding and air leakage, and make the vacuum chamber always maintain the required vacuum degree.

Each operation of vacuum metallurgy needs to meet a certain degree of vacuum, and different operations have different requirements for the degree of vacuum.

Now a variety of vacuum pumps have been produced. They are constructed according to different pumping principles, have different characteristics and reach different starting and stopping pressures. They are also suitable for operation under a certain range of pressures.

Due to the different pressure of various vacuum pumps, when the working pressure is low, two or more vacuum pumps should be used to meet the needs.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)