Vacuum pump for refining edible oil

In the refining process of edible oil, most of the water vapor is pumped out by vacuum pump, so the selected vacuum pump must be able to extract water vapor. The main vacuum pumps that can extract water vapor are water jet pump, water ring pump, wet Roots pump, water vapor jet pump and cryogenic condensation pump. In front of rotary vane pump, reciprocating pump, slide valve pump, Roots pump and dry pump, water vapor condenser (cold trap, water catcher, condensation pump) can also pump out a certain amount of water vapor. No matter which kind of vacuum pump can not achieve the vacuum required for cooking oil refining alone, it needs to be equipped with a vacuum system.

At present, the main vacuum systems commonly used in deodorization of edible oil refining distillation are: multi-stage jet vacuum pump (i.e. 3-4 stage steam jet pump, 2-3 stage steam jet pump + water jet pump); multi-stage volumetric vacuum pump (i.e. 2-3 stage Roots vacuum pump + rotary vane vacuum pump, 2-3 stage Roots vacuum pump + water ring vacuum pump); combination of jet vacuum pump and volumetric vacuum pump (i.e. two-stage Lo). Cis vacuum pump + water jet pump, steam jet pump + water jet pump, 2 ~ 3 class steam jet pump + water ring vacuum pump.

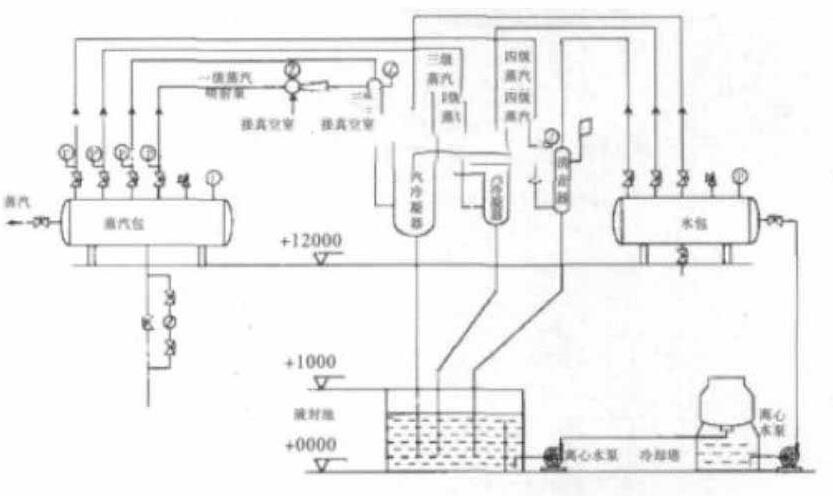

Vacuum System of Multi-stage Steam Jet Pump

The system consists of four-stage steam jet pump and two-stage atmospheric condenser, which is the most commonly used vacuum system in the traditional deodorization process of edible oil refining. Its main advantages are simple structure, long service life, large exhaust capacity, insensitivity to dust, etc. Its main disadvantage is that it needs to consume a large amount of working steam and cooling water. The amount of steam consumed in deodorization process accounts for more than 60% of the total steam consumption in refining process. It needs to be equipped with boiler system, so it has high energy consumption and high cost, and the working steam directly contacts with the deodorized components to condense. A large amount of wastewater is produced when it flows into the pond. The volatilization of wastewater causes air pollution, and wastewater needs to be treated. The cost is relatively large. The overhead water jet pump covers a large area and space, and its maintenance is inconvenient. Obviously, the system has many shortcomings and is being phased out.

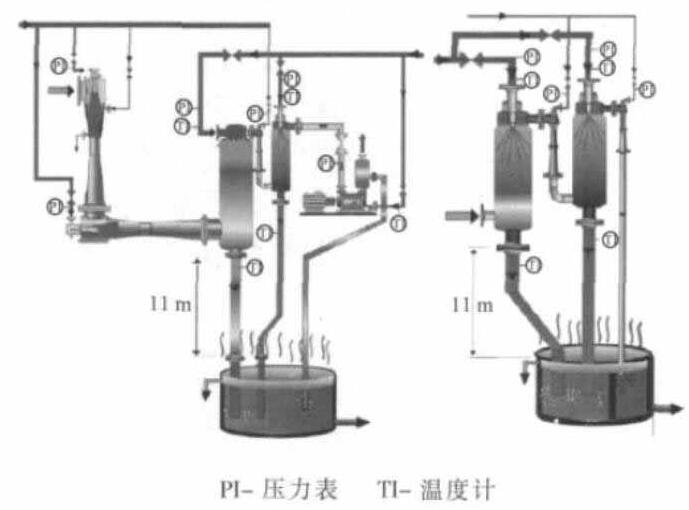

Vacuum System of Steam Jet Pump and Water Ring Pump

A vacuum system consisting of a steam jet pump and a water ring pump. In the multi-stage steam jet pump, the water ring pump replaces the last stage steam jet pump or the last two stage steam jet pump to form the steam jet pump and the water ring pump unit. The system can make full use of the higher pumping capacity of the high vacuum steam jet pump and the higher pumping efficiency of the low vacuum water ring pump. It can also reduce the consumption of steam and spray water and save energy. At the same time, because the water ring pump can be made into a closed cycle system, the working fluid can be recycled after cooling through the heat exchanger, which avoids the discharge of process liquid and produces less sewage, which is conducive to environmental protection. Moreover, the whole system does not need to start the pump, so it can start quickly and realize the stable operation of the vacuum system.

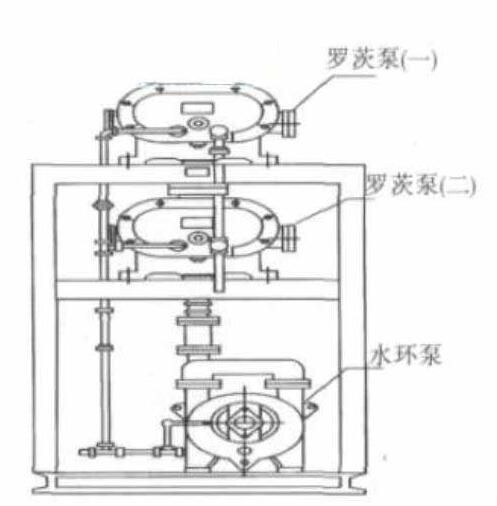

Roots Vacuum Pump-Water Ring Pump Unit

The characteristics of Roots Vacuum Pump-Water Ring Pump Unit are as follows:

1. In Roots vacuum Pump-Water ring pump unit, there is a certain gap between the rotor of Roots vacuum pump and the pump chamber, between the rotor and the rotor, which is not in contact with each other and does not need oil lubrication.

2. The rotor of Roots vacuum pump has good geometric symmetry, which can improve the rotational speed, so that a compact pump can be manufactured.

3. Roots Vacuum Pump-Water Ring Pump Unit has small vibration and large volume when working.

4. There is no compression phenomenon like mechanical vacuum pump in Roots vacuum pump chamber, so it does not need exhaust valve. Because of this, condensable fatty acid vapor can be removed.

5. Fast start-up, can reach the limit vacuum in a short time, low power consumption, low operation and maintenance costs;

6. Roots vacuum pump has a large pumping speed in a wide pressure range (1 Pa~1000 Pa) and can expel distilled gas rapidly.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)