vacuum pump structure and transmission mode

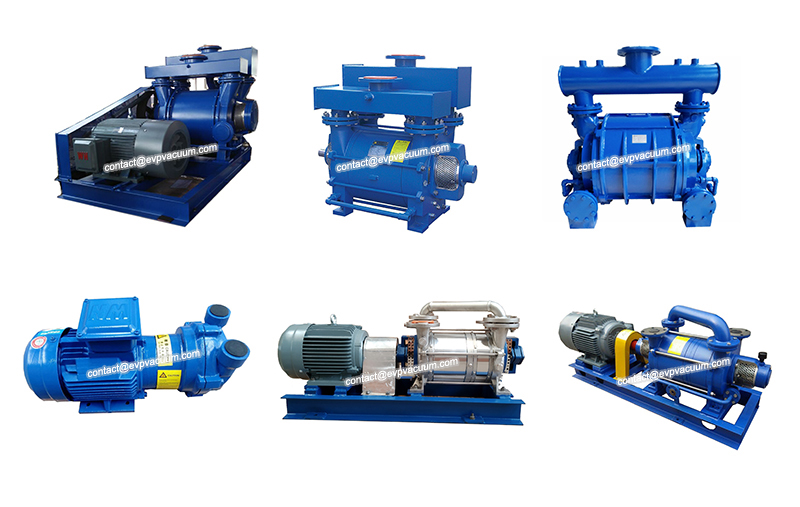

Vacuum pump is a large quantity and wide range of products with large output and low output value, but it is indeed an essential basic product that directly affects the performance and quality of vacuum complete equipment. Vacuum pump from high / Ultra vacuum to coarse / low vacuum, its products can be roughly divided into 14 categories:

High / Ultra vacuum: low temperature pump, molecular pump, sputtering ion pump, titanium sublimation pump, diffusion pump.

Medium vacuum:dry vacuum pump, two-stage rotary vane pump, roots vacuum pump, oil booster pump, water vapor jet pump.

Coarse / low vacuum:single stage rotary vane pump, slide valve pump, liquid ring vacuum pump, reciprocating vacuum pump.

The market of vacuum pump changes dynamically according to the needs of users. The main driving force of market growth comes from the rapid development of semiconductor industry and the expanding application fields of dry pump and molecular pump.

With the rapid development of China’s industry, the application of vacuum pump is more and more extensive. For example, in plastic machinery, pesticide chemical industry, dye chemical industry, low-temperature equipment pharmaceutical chemical industry, food machinery, electronic industry, vacuum equipment and other fields. In order to let the industry better understand the vacuum pump, EVP vacuum pump manufacturer specially collated a detailed information about the structure and transmission mode of vacuum pump.

The overall structure of the vacuum pump is determined by the arrangement of the pump body. The vertical structure has horizontal inlet and outlet, and it is convenient to assemble and connect pipelines. However, the center of gravity of vacuum pump is high and its stability is poor at high speed, so this type of pump is mostly used for small pump.

The air inlet of the horizontal pump is on the top and the air outlet is on the bottom. Sometimes, in order to facilitate the installation and connection of vacuum system pipes, the exhaust port can be connected from the horizontal direction, that is, the inlet and exhaust directions are mutually perpendicular. At this time, the exhaust port can be opened from the left or right direction. In addition to connecting one end of the exhaust pipe, the other end is blocked or connected with the bypass valve. The pump has low center of gravity and good stability at high speed. Generally, large and medium-sized pumps use this structure.

The two rotor shafts of the vacuum pump are installed vertically with the horizontal plane. The assembly clearance of the structure is easy to control, the rotor is easy to assemble and the pump occupies a small area. However, the center of gravity of the pump is high and the gear is inconvenient to be disassembled, and the lubricating mechanism is relatively complex. The two rotors of the vacuum pump are operated synchronously by a pair of high-precision gears. The driving shaft is connected with the motor through the coupling.

There are mainly two types of transmission structure: one is that the motor and gear are placed on the same side of the rotor. Driven rotor is directly driven by the motor end gear, so that the torsional deformation of the active rotor shaft is small, the gap between the two rotors will not be changed due to the large torsional deformation of the active shaft, so that the gap between the rotors is even in the operation process. The biggest disadvantages of this kind of transmission mode are: A. There are three bearings on the driving shaft, which increases the difficulty of pump processing and assembly, and the disassembly and adjustment of gears are also inconvenient; B. the overall structure is uneven, and the center of gravity of the pump is inclined to one side of the motor and gearbox.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)