Vacuum pump used in freeze drying of dairy products

Vacuum pump used in the production of granular skimmed mare milk powder

At present, more and more people are paying attention to the preservation and extension of the food quality guarantee period. The process of preservation and extension of the food quality guarantee period should be mild, and the ingredients of the food should not be changed or destroyed, nor should any additives be added. Therefore, to meet these needs, vacuum freeze-drying has gradually become an excellent storage method.

This method takes advantage of the physical properties of water, that is, water can directly change from a solid state to a gas state in a vacuum state. This process is called sublimation. In the freeze-drying process, quick-frozen food is placed in a vacuum environment and heated and dried. This process prevents the frozen water in the frozen food from melting, but evaporates in the form of water vapor. The operating temperature is much lower than -50°C. It is one of the gentlest methods for drying food, because it does little damage to the product itself.

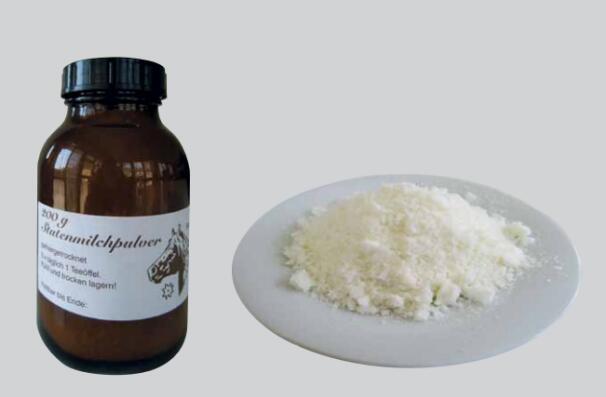

One of the most famous products processed by freeze-drying is granular skimmed milk powder. Granular milk powder keeps longer and retains all its nutritional value.

Because of its high quality and rich nutritional value, horse milk is becoming more and more popular. It is especially easy to digest, low in fat, and rich in minerals and enzymes.

Figure 1: Skim mare milk pellets produced by using vacuum drying

In particular, it has a higher content of isoenzymes and lactoferrin, which is very suitable for the medical industry. These enzymes are antibacterial and antibacterial, so they are also called natural antibiotics. For example, mare’s milk is recommended for the treatment of allergies, eczema, Crohn’s disease, metabolic disorders, and to improve the immune system and support the treatment. It can be used not only as food, but also in cosmetics. Mare milk is a veritable fountain of youth: it contains unique proteins, amino acids, lipids and minerals, which are ideal for relieving dry, dehydrated and wrinkled skin.

The mare milk farm uses freeze dryers to process mare milk into milk pellets. Even if these milk particles are transported over long distances, they will not cause loss of nutritional value.

In order to obtain the vacuum environment necessary for freeze drying, the manufacturer chose the solution provided by EVP Vacuum.

The mare’s milk was freeze-dried by EVP vacuum solution.

The freeze-drying equipment of the Mare’s Milk Farm is consists of circular stacked shelves, sealed by a bell-shaped container outside. Mare’s milk is taken directly from the refrigerator at about -34°C and placed on these shelves. Then, creating a low vacuum environment in an airtight bell-shaped glass container. The vacuum is obtained by a two-stage rotary vane pump with magnetic coupling technology. Because of its solid performance, easy maintenance, and high reliability.

Once the final pressure of about 1 hPa, which is lyophilized required to achieve, the system is heated to the rack, the water will sublimate milk – i.e. converted to a gas. A large capacitor between the bell-shaped glass container and the vacuum pump causes the water vapor to condense at 60°C. The complete freeze-drying process takes about one day.

The system can process 8 liters of mare’s milk into dry milk pellets per day. In contrast to cows, mares only milk their foals when they are present and well fed. Therefore, compared with dairy cattle fattening farms, the amount of milk obtained is much less, but the method of extracting milk is natural and harmless.

The advantages of the vacuum solution are as follows:

■ High operating safety

■ Firm structure, high reliability

■ Maintenance-free equipment

■ Compact structure, easy system integration

The vacuum system ensures the excellent quality and effective storage of mare milk. The vacuum solution used can fully meet customer requirements for vacuum pumps, that is, high reliability and durability, and long service life.

Figure 2: Freeze-drying at mare milk Farm

Figure 3: Rotary vane pump in freeze-drying equipment

We provide one-stop vacuum solutions

EVP VACUUM stands for providing customers with innovative and customized vacuum solutions, perfect technology, comprehensive support and reliable services worldwide.

Complete product line

From an accessory to a complex vacuum system: we are the only supplier that can provide a complete product line and technical services.

Perfect combination of theory and practice

We have decades of professional technology and perfect training system! We can provide you with a complete production technology improvement program and a global unified first-class field service.