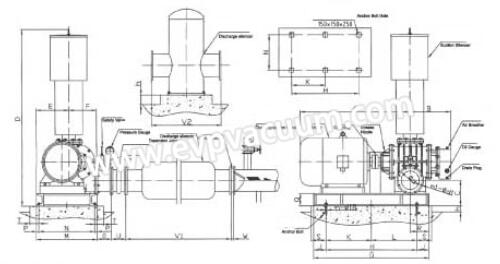

Directly connected to Roots blower

I want to buy directly connected Roots blower from EVP Company.

Directly connected to the safe operation of roots blower type and service life, often depends on whether the correct maintenance and maintenance, and attention should be paid to any accident to believe, if long time don’t use direct type roots blower, will cut off all the power on the its body and placed it in a dry and ventilated places, so that it can effectively avoid the body in the long term is not in use and produce the phenomenon such as rust. In addition, in the use process of Roots blower to oil it regularly, only in this way can maximize to ensure the flexibility of the operation of three blades Roots blower.

Size:

Strong strength, perennial to stainless steel; Cast iron; Cast steel material directly connected roots blower product production, its main use is exhaust. There are many types of products, among which SSR is popular and popular. The weight is 500kg, and the product types can be supplied according to customers’ requirements. In the development of fan and exhaust equipment industry, we mainly provide small and medium-sized enterprises with directly connected Roots fan and other products.

Install roots blower

Before installing roots blower, parts to be used should be cleaned and inspected

In the process of using Roots blower, it is often found that the current of equipment is too high, and then a series of problems occur. Once the current of the equipment is too high, the motor will be overloaded and then affect our normal operation. Then what is the cause of the overflow of roots blower?

As the outlet of the fan is not clear and the wind is blocked, the pressure rises, and the motor becomes overvoltage overload, the pipe is blocked, and then the equipment ammeter rises. Faulty operation of current overload may also cause problems during operation. For example, if the device is reversed, the valve is not fully open, and this operation may result in instantaneous motor combustion.

In the operation, should be carried out in accordance with the provisions, do not cause unnecessary trouble. Lubricating Oil In the absence of lubricating oil for the equipment, the fan will continue to operate without lubricating oil. The impellers collide, the gears wear away at each other, and the load on the motor increases. It will only increase the burden of the motor to accelerate the loss.

The problem of the fan itself is the quality problem in the factory. When installing a fan, many components are poorly combined, which can create rating conflicts.

Roots blower manufacturer maintenance and parts replacement rules, based on blower failure analysis of the preparation work, confirm the location and scale of maintenance, prepare parts that may need to be replaced. Prepare appropriate inspection items and measuring tools according to the structure of the parts. According to the quality of the blower, the overhaul plan was made.

Implement safety measures. When removing precautions, the size of important parts and the orientation of the device should be marked so that the check mark is reset during assembly to prevent seizures. For example, the thickness of various gaskets is measured and recorded, the clearance of various parts of the rotor is measured and recorded, and a set of summaries are made of the main and driven gears and corresponding symbols on the tooth slots.

Before installing roots blower, parts to be used should be cleaned and inspected. With respect to disassembled parts, the appearance of the machining shall be protected and placed in accordance with certain rules. Parts of the same part, such as bearing housing, bearing gland and adjusting washer of the same part, shall be put together. The missing parts should be included in the special equipment. Matching applications should be stored together.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)