vacuum pump vacuum system for Vacuum coating machine

Provide equipment and vacuum coating process for 3D parts used in automotive lamp or interior lighting industry. Such as headlights and taillights, rearview mirrors, interior lighting, etc. Reflective coating and hydrophobic coating (lotus effect) process are typically used in automotive headlights, taillights and interior lighting.

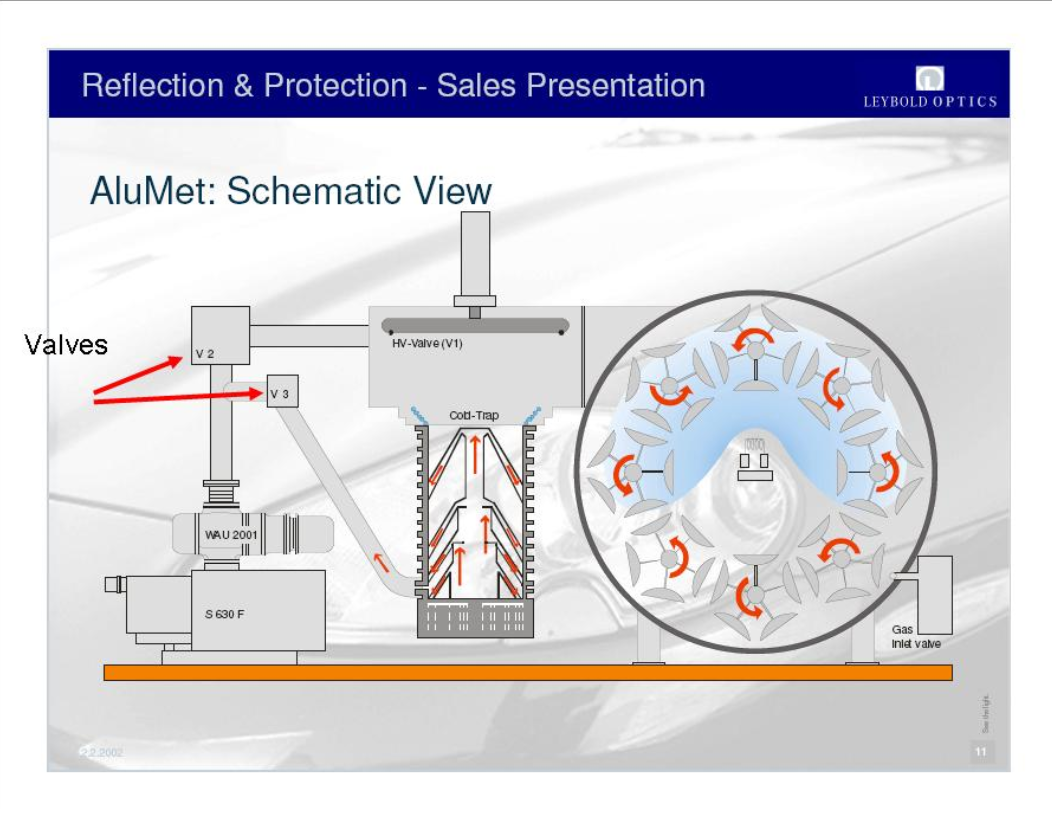

Plasma enhanced chemical vapor deposition (PECVD) is used for surface coating corrosion protection of reflective and decorative metal layers with combination of sputtering, thermal evaporation. Further application is through reactive magnetron sputtering, transparent layer surface engineering, such as wipe layer and easy to clean layer (with lotus effect), layer stack is the highest reflectivity of automobile rearview mirror and silver layer stack.

According to the type of vacuum chamber, the vacuum coating equipment of automatic lamp produced by our company can be divided into horizontal and vertical type. The main functions of the equipment include: high-pressure ion bombardment, one-time aluminum plating in the vacuum chamber and extra hard protective film (SIO). The superhard protective film improves the anti nitriding ability of the aluminum layer and keeps the long-term high reflectivity of the aluminum layer. The reflective film of the automobile lamps and lanterns has reached the national standard of automobile lamps and lanterns, and passed the experiments of acid resistance, alkali resistance and salt resistance. The equipment adopts computer to control and monitor the operation status and coating process of the equipment. It improves work efficiency, ensures the stability and consistency of product quality, and reduces the influence of human factors.

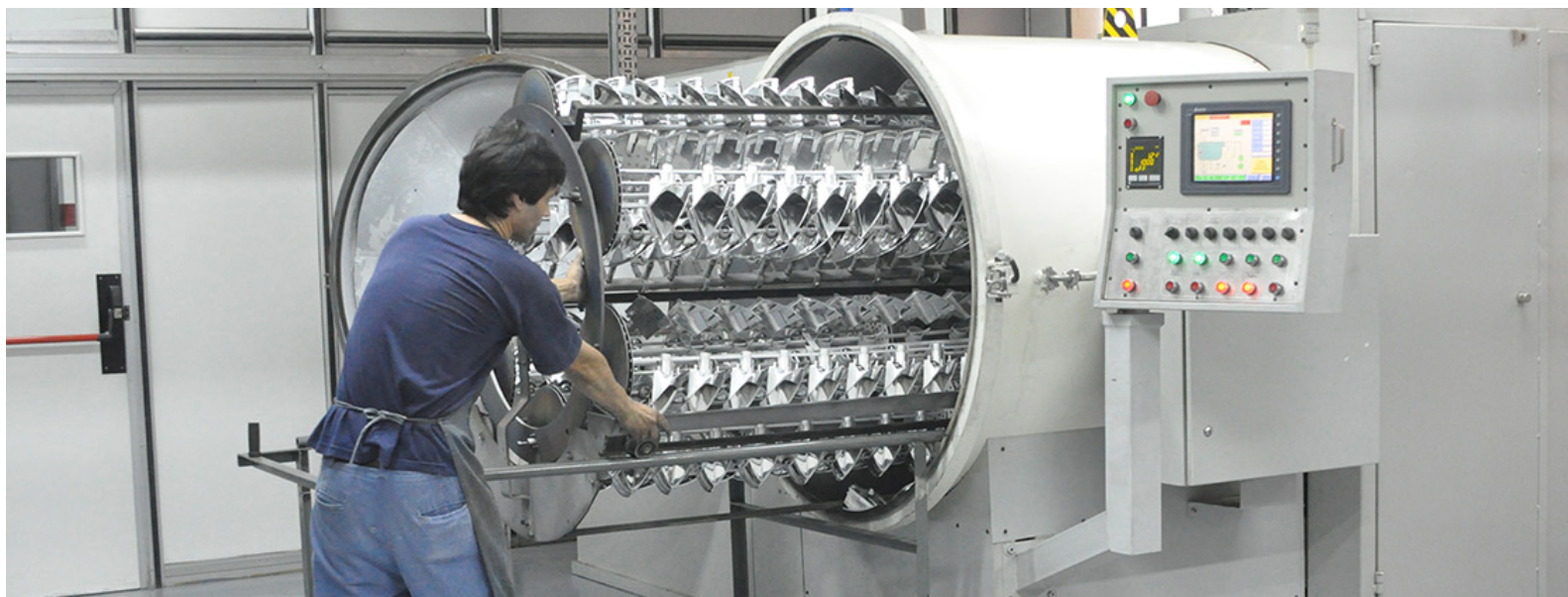

Coating machine (for lamp coating, in vacuum environment, evaporated aluminum wire covers the plastic surface with aluminum)

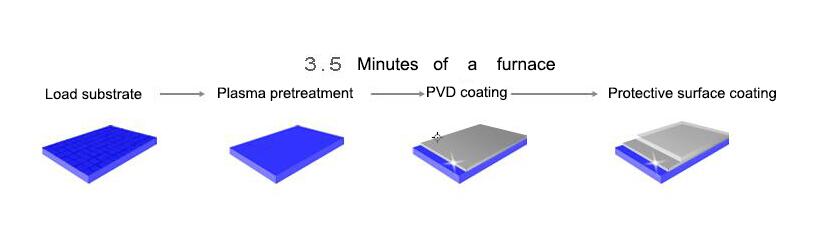

The reflective coating of automobile headlights and taillights made by injection molding in plastic mold is realized by Al (aluminum) with reflectivity of 90% and Ag (silver) with reflectivity of 95% – 98%. The reflective coating of vacuum equipment exceeds the specifications of all headlights, greatly exceeds the standard of NaOH test for 10 minutes in automobile industry. Our system is designed to have very fast work Cycle, can cooperate with injection molding machine production line operation. The following are four steps of high-speed, high-quality automobile lighting coating process:

Vacuum coating machine for roof coating

Detailed introduction of “configuration table of vacuum coater”

1、vacuum unit

Vacuum coating machine for vacuum system (diffusion + Roots + rotary disc)

1. 2×30 rotary vane pump (Nanguang)

2. 2×70 rotary vane pump (Nanguang)

3. Rto300s roots pump (Ziman)

4. Kt500 diffusion pump (Zhenlong)

5. Valve: gdz2x500a high valve (all stainless steel structure), maintenance valve, front stage valve and pre extraction valve are gdq100 (all stainless steel structure), ddc65 and ddc80 electromagnetic charging valves (Shanghai two valves), and bypass valve is the valve installed in roots pump;

2、Tank

1. TISCO SUS304 stainless steel with water-cooled jacket structure, inner size 1500 * 1600mm, inner wall plate thickness of 10 mm, outer wall plate thickness of 5 mm; twelve arc source positions, divided into four columns, three staggered arrangement in each column.

2. 2 sets of workpiece support rods, 19mm;

3. 2 sets of inner lining plates

4. Air distribution pipeline

5. Air filter is added to the air release valve

3、standard parts: sealing ring, air circuit parts (two position five way solenoid valve is imported from Germany Burkert products), stainless steel water valve, stainless steel water circuit connector, stainless steel screw, pressure gauge, thermocouple, motor, reducer and wooden box packaging, etc.

4、 heater: U-shaped tubular 15kw, center + periphery

5、Workpiece turntable: lower turntable, 6 stations, rotation diameter 370mm, with shield cover.

6、arc source (including power supply) titanium target 100, pneumatic arc striking; DC inverter arc power dc160a (Shenzhen Ruiling)

7、Mass flowmeter: Seven Star Huachuang d07-7b 500sccm

8、Full automatic electrical control system: Mitsubishi FX2N series PLC and weinview touch screen, fcs410 gas flow controller, hy99401b compound meter, flx12 grating valve angle controller, contactor, air switch, circuit breaker, relay, switch button, island electric temperature control meter, digital electric pressure meter, frequency converter, potentiometer, cabinet, panel, wiring (main components are foreign brands, Weiwei DeMille, Mitsubishi, Schneider, etc.)

9、bias power supply: pulse inverter pls30kw (Zhuhai Shengpu, etc.)

10、random spare parts: Seal drawing, bearing, oil seal, special tools, etc.