Vacuum Pumps Application

Speaking of the application of vacuum pumps, there are too many, because there are many types of vacuum pumps, which are widely used in plastic machinery, pesticide chemical industry, Dyestuff Chemical industry, brick and tile machinery, cryogenic equipment, paper-making machinery, pharmaceutical chemical industry, food machinery, industrial electric furnace, electronic industry, vacuum equipment, petrochemical industry, metallurgy, mining and foundation treatment and other fields.

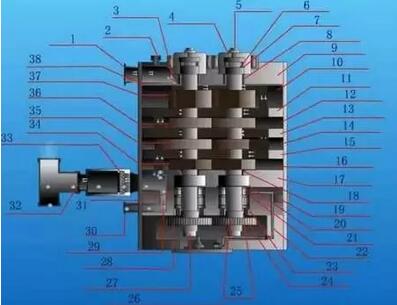

Claw type dry vacuum pump

Claw-type dry vacuum pump completes the suction and exhaust process by changing the volume of the closed cavity formed by the clearance and friction-free meshing between the claw-type rotors connected on two axes, between the rotors and the inner wall of the pump chamber, and between the rotors and the diaphragms.

The structure of claw type dry vacuum pump generally adopts the form of multi-stage rotor in series or Roots rotor in series with multi-stage rotor to form a multi-stage claw type dry vacuum pump.

As shown in the figure, the four-stage pump chambers are connected in series, and each stage pump chamber has a pair of claw-type rotors which engage in synchronous reverse motion.

The first stage pump chamber in the fourth stage pump chamber is the suction stage, and its suction volume is larger than the latter three stages, forming inter-stage compression.

Four pairs of rotors are mounted on two parallel axles. The axles are supported by bearings at the upper and lower ends. There is a separator between the pump chamber stage and the stage, and there is a suction and exhaust passage on the separator.

When the motor is installed upside down, the power is transmitted to the rotor shaft through the ferry gear. The rotor shaft is driven by a pair of synchronous time-limited gears, and the phase of the rotor is adjusted and fixed.

There is a small gap between the rotor and the inside of the pump chamber. The rotor suspended in the pump chamber makes the overflow part free of any substantive contact friction and lubrication. This ensures that the claw pump can maintain the limit vacuum, pumping speed, compression ratio unchanged for a long time and has a long service life.

Claw Dry Vacuum Pump Characteristic:

1. The pump chamber does not contain any medium, such as oil, and is clean for pumping. It does not pollute the environment.

2. High vacuum, up to 3 3a.

3. It has simple structure, easy operation and maintenance, and low operation cost.

4. It can work continuously under high pressure for a long time with low noise.

5. It can extract corrosive gases, toxic gases, flammable and explosive gases, radioactive gases, dusty gases and condensable gases (such as water vapor, organic gases, etc.).

6. It can be used as a gas transmission pump with good compression ratio up to 10-105.

7. The rotor pair is suspended in the pump chamber, the rotor pair is not in contact with the pump chamber, there is no friction, and the service life is long.

Claw Dry Vacuum Pump Application:

Petrochemical industry:

1.It can extract acidic gases, such as tetrahydrofuran.

2.Can extract condensable gases: such as alcohol, gasoline, etc.

3.It can extract flammable and explosive gases, such as oxygen, hydrogen, methane, etc.

4.Anti-corrosion series can extract strong acidic gases, such as hydrogen chloride, hydrogen fluoride, sulfuric acid, etc.

Pharmaceutical industry: crystallization, distillation, sublimation, drying, deodorization, polymerization, vacuum evaporation, negative pressure filtration, monomer recovery, adsorption/desorption, material transport decay, corrosive media, ethylene oxide disinfection, etc.

Food industry: sublimation, drying, dehydration, vacuum evaporation, vacuum preservation, vacuum packaging, etc.

Scientific research institutes: rotary steaming, distillation, distillation, polymerization, negative pressure filtration, vacuum drying, pilot plant, wind tunnel test, vacuum environment simulation, etc.

Electron photovoltaic: impregnation, vacuum coating, ion etching, molecular beam epitaxy, etc.

Aerospace and Aerospace: Brazing, Vacuum Coating, Electron Beam Welding, Wind Tunnel Test, Space Environment Simulation, etc.

Metallurgical industry: impregnation, extrusion, vacuum coating, ion etching, sludge degassing, molten steel degassing, molecular beam epitaxy, etc.

Nuclear industry: zero leakage claw pump can remove UF6 gas

Other industries: central air conditioning, indoor vacuum, sewage treatment, lithium battery manufacturing, etc.

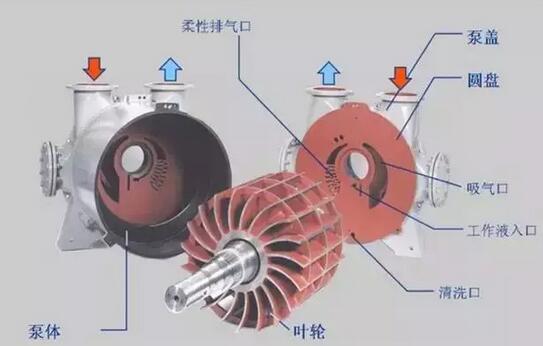

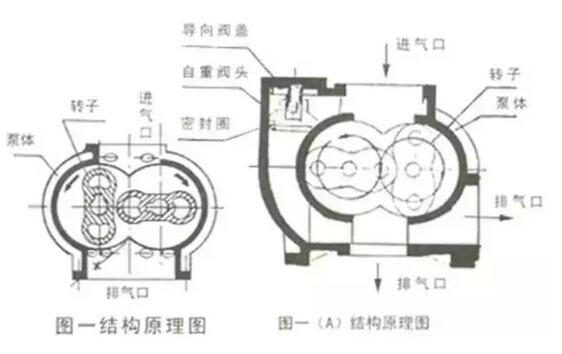

Water ring pumps can be divided into the following types according to different structures:

Single-stage single-acting water ring pump: single-stage refers to only one impeller, single-acting refers to the impeller every rotation cycle, suction, exhaust once. This kind of pump has higher limit vacuum, but lower pumping speed and efficiency.

Single-stage double-acting water ring pump: single-stage refers to only one impeller, double-acting refers to the impeller every rotation of a week, suction, exhaust twice. Under the same pumping speed, the size and weight of double-acting water ring pump are much smaller than that of single-acting water ring pump. Because the working chamber is symmetrically distributed on both sides of the pump hub, the load acting on the rotor is improved. The pumping speed and efficiency of this kind of pump are higher, but the limit vacuum is lower.

Double-stage water ring pump: Most of the double-stage water ring pumps are single-acting pumps in series. Essentially, the impellers of two single-stage single-acting water ring pumps are joined together by a common spindle. Its main characteristic is that it still has a large pumping speed at a higher vacuum, and its working condition is stable.

Atmospheric Water Ring Pump: Atmospheric Water Ring Pump is actually a unit of air ejector series water ring pump. The air pump in series in front of the water ring pump is designed to improve the limit vacuum and expand the use of the pump.

Compared with other types of mechanical vacuum pumps, water ring pumps have the following advantages:

1.The structure is simple, the manufacturing accuracy is not high, and it is easy to process. Simple operation and convenient maintenance.

2.Compact structure, the pump is usually directly connected with the motor, with a high speed. With smaller structure size, larger exhaust volume can be obtained.

3.There is no metal friction surface in the pump chamber, so there is no need to lubricate the pump. The sealing between the rotating part and the fixing part can be accomplished directly by the water seal.

4.The temperature change of the compressed gas in the pump chamber is very small, which can be considered as isothermal compression. Therefore, flammable and explosive gases can be removed.

5.Because there is no exhaust valve and friction surface, dust-laden gas, condensable gas and gas-water mixture can be removed.

water ring pump shortcomings :

1.Low efficiency, generally around 30%, better up to 50%.

2.Low vacuum. This is not only due to structural constraints, but also to the saturated vapor pressure of the working fluid.

Generally speaking, water ring pump has been widely used because of its outstanding advantages of isothermal compression and water sealing, which can extract flammable, explosive and corrosive gases, dust and moisture.

Water Ring Vacuum Pump Application :

Application in power industry: condenser vacuum pumping, vacuum water absorption, flue gas desulfurization, fly ash transportation, turbine sealed pipe exhaust, vacuum exhaust, geothermal exhaust.

Petrochemical industry : gas recovery, gas recovery, gas pressurization, enhanced oil recovery, gas collection, crude oil stabilization, vacuum distillation of crude oil, exhaust compression, steam recovery/gas pressurization, filtration/dewaxing, tail gas recovery, polyester production, PVC production, packaging, cyclic gas compression, pressure swing adsorption (PSA), production, acetylene and hydrogen, etc. Explosive gas compression, vacuum system on top of tower in vacuum distillation of crude oil, vacuum crystallization and drying, vacuum filtration and vacuum transportation of various materials.

Manufacturing industries: drying (pallets, rotations, reversals, cones and freeze dryers), reproducing/reactor drying, distillation, degassing, crystallization/vaporization, filling and/or material transfer.

Pulp and paper production: black liquor evaporation, crude pulp washer, lime slurry and filter, precipitate filter, vacuum dehydrator, raw material and white water degassing system, mixing box compressor, suction box, suction roll and transfer roll, vacuum pressing, wool suction box, blower box.

Plastic industry: extruder degassing, setting table (profile), EPS foaming, drying, pneumatic conveying device, vinyl chloride gas extraction and compression.

Application in instruments: Steam sterilization, breathing device, pneumatic mattress, protective clothing, dental instrument, central vacuum system.

Environmental protection industry: wastewater treatment, biogas compression, vacuum water addition, wastewater purification/activated sludge tank oxidation, fish pond ventilation, waste gas recovery (biogas), biogas recovery (biogas), waste treatment machine.

Food and beverage industry: salmon cleaner, mineral water degassing, salad oil and fat deodorization, tea and condiment sterilization, sausage and ham production, tobacco products humidification, vacuum evaporator.

Packaging industry: filling bags with air, opening bags by means of air extraction, transporting packaging materials and products, attaching labels and packing articles with glue, lifting cardboard boxes by means of vacuum manipulators, and assembling, vacuum packaging and ventilation packaging (MAP), PET container production, drying of plastic particles, conveying and extruding of plastic particles. Machine degassing, injection moulding, film removal and treatment of injection moulding parts, drying of injection moulding parts, blow moulding of bottles, plasma treatment, to set up isolation layer, pneumatic conveying of bottles, filling and filling, labeling, packaging and moulding, recycling.

Wood processing industry: maintenance and snatch, wood drying, wood preservation, log impregnation.

Marine industry: condenser exhaust, central vacuum pumping, marine low pressure air compressor, turbine sealed pipe exhaust.

Facility treatment: drying floor, water pipeline anti-corrosion protection, central vacuum cleaning system.

Metallurgical industry: steel degassing.

Sugar industry: preparation of carbon dioxide, filtrate of dirt, application in evaporator and vacuum sucker.

Key Points for Selection of Water Ring Vacuum Pump

I. Determination of Types of Water Ring Vacuum Pumps

The type of water ring vacuum pump is mainly determined by the medium pumped, the amount of gas required for operation, the vacuum degree or the exhaust pressure.

Two points should be paid attention to after the water ring vacuum pump works properly:

1. As far as possible, the vacuum degree of the selected vacuum pump is required to operate in the high efficiency range, that is, in the critical vacuum degree or the critical exhaust pressure area, so as to ensure that the vacuum pump can work normally according to the required conditions and requirements. Avoid operating near the maximum vacuum or exhaust pressure range of the vacuum pump.

Operating in this area, not only the efficiency is very low, but also the work is very unstable. It is easy to make the vacuum pump produce vibration and noise. For vacuum pumps with high vacuum, cavitation often occurs when they operate in this region. The obvious phenomenon is noise and vibration in the vacuum pump. Excessive cavitation will cause damage to the pump body, impeller and other parts, so that the vacuum pump can not work properly.

It can be seen that when the vacuum or gas pressure required by the vacuum pump is not high, it can be preferentially selected in the single-stage pump. If the requirement of vacuum or exhaust pressure is high, the single stage pump can not always meet the requirement, or the requirement that the pump still has a larger air volume at a higher vacuum, that is to say, the performance curve should be flat at a higher vacuum, so the two stage pump can be chosen. If the vacuum requirement is above – 710 mmHg, Roots water ring vacuum unit can be selected as the vacuum pumping device.

2. Correct selection of vacuum pumps according to the pumping capacity required by the system

If the type of vacuum pump or vacuum unit is selected, the correct type should be selected according to the pumping capacity required by the system.

Dry screw vacuum pump is a kind of suction and exhaust equipment which uses a pair of screw to synchronize high-speed reverse rotation in the pump housing.

Dry Screw Vacuum Pump Characteristics:

1. High reliability. The screw dry vacuum pump has few parts and no vulnerable parts, so it runs reliably and has a long service life.

2. Easy operation and maintenance.

3. Good dynamic balance. The screw dry vacuum pump has no unbalanced inertia force, and the machine can run smoothly and at high speed.

4. Strong adaptability. The screw dry vacuum pump has the characteristics of forced gas transmission. It can maintain a high pumping speed in a wide range of pressure, and the exhaust volume is almost unaffected by the exhaust pressure.

5. Multiphase Mixed Transport. Because there is a small gap between the tooth surfaces of the rotor of the screw dry vacuum pump, it can remove corrosive, toxic, dust, condensable vapor and other gases.

Dry Screw Vacuum Pump Application :

Screw dry vacuum pumps are widely used in electronics, nuclear energy, chemical industry, medicine, food industry and other fields. In the semiconductor industry, it is used to produce chips, liquid crystal displays, etching and CVD process of PLASMA.

In nuclear industry, it is used for vacuum acquisition in nuclear reactor and nuclear industry; in chemical industry, it is used for vacuum distillation and solvent extraction to recover solvents efficiently; in fatty acid production, it is used to eliminate water pollution and remove obstructions in ejectors; in pharmaceutical industry, it is used to recover pharmaceutical liquid and drug intermediates, to provide clean sterile conditions for the production of artificial organs, and to recover gas disinfectants; in food industry, it is used for perfume. Flavor concentrate, food packaging and so on.

It has a wide range of applications. Specifically as follows:

Specific applications: drying treatment, vacuum distillation, molecular distillation, solvent recovery, oil and gas recovery, factory ordinary vacuum, electronics, vacuum coating, aviation, nuclear industry can extract ordinary air, flammable and explosive gases, corrosive gases, especially to meet the requirements of a clean vacuum environment. Specific applications: vacuum coating, vacuum distillation, vacuum drying, pulling single crystal, special gas manufacturing, ion etching, etc.

Dry vacuum pumps are used in textile and metallurgical industries in spandex, aramid, fibre, metallurgy and other related processes, such as vacuum defoaming, VOD vacuum oxygen blowing decarbonization, etc.

One is the semiconductor industry, which requires the vacuum pump to return to zero in the pumped space to protect the workpiece from pollution. The requirements for vacuum systems used in semiconductor industry are generally divided into three levels.

1.Under clean conditions, only air or air containing a little water vapor is pumped out.

2.Under moderate conditions, the reaction gas in the process is extracted, but there is no solid particulate matter.

3.Exhaust under harsh conditions to remove chemical reactants (toxic or even carcinogenic) and solid particles.

The other is represented by the petrochemical industry, which requires vacuum pumps to extract a large number of condensable gases, or corrosive gases, or toxic gases, or gases containing micro-dust. Screw dry vacuum pumps are widely used in electronics, nuclear energy, chemical industry, medicine, food industry and other fields. In the semiconductor industry, it is used to produce chips, liquid crystal displays, etching and CVD process of PLASMA.

In nuclear industry, it is used for vacuum acquisition in nuclear reactor and nuclear industry; in chemical industry, it is used for vacuum distillation and solvent extraction to recover solvents efficiently; in fatty acid production, it is used to eliminate water pollution and remove obstructions in ejectors; in pharmaceutical industry, it is used to recover pharmaceutical liquid and drug intermediates, to provide clean sterile conditions for the production of artificial organs, and to recover gas disinfectants; in food industry, it is used for perfume. Flavor concentrate, food packaging and so on.

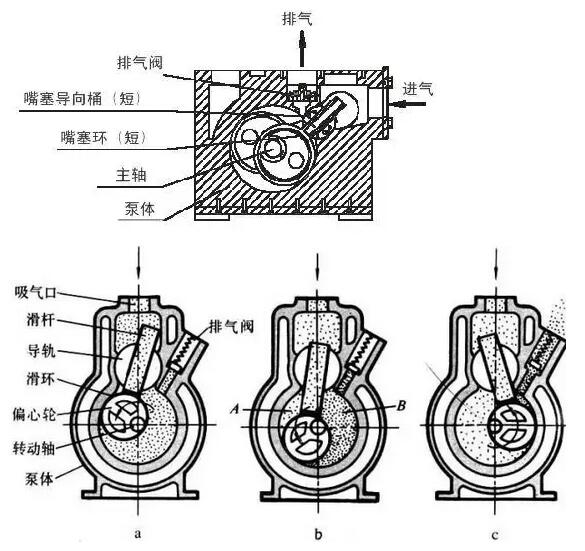

Reciprocating vacuum pump

Reciprocating vacuum pump (also known as piston vacuum pump) is one of the low vacuum acquisition equipment. Reciprocating vacuum pump makes the piston reciprocating in the cylinder by connecting rod crankshaft mechanism, periodically changes the volume of suction and exhaust chamber, and relies on suction and exhaust valve to complete suction and exhaust action, so as to obtain vacuum.

Its limit pressure is generally 1330-2660P reciprocating vacuum pump (referred to as reciprocating pump), also known as piston vacuum pump, which belongs to one of the low vacuum acquisition equipment. Compared with the rotary vane vacuum pump, it can be made into a pump with large pumping speed, and the efficiency is slightly higher than that of the water ring vacuum pump. The main drawbacks of this kind of pump are its complex structure, large volume and large vibration in operation. It can be replaced by liquid ring vacuum pump in many cases.

Reciprocating vacuum pump has a wide range of pumping speed, ranging from 50L/S to 600L/S. It is suitable for vacuum impregnation, vacuum treatment of molten steel, vacuum distillation, vacuum evaporation, vacuum concentration, vacuum crystallization, vacuum drying, vacuum filtration and vacuum operation of concrete in petroleum, chemical, pharmaceutical, food, light industry, metallurgy and electrical industries.

Reciprocating vacuum pumps are not suitable for pumping gases with excessive oxygen, explosive, corrosive to metals, and particulate dust, nor for conveying gases from one container to another. Reciprocating vacuum pump is suitable for pumping non-solid particles, non-corrosive gas. This kind of vacuum pump has higher pumping rate and higher vacuum. Therefore, it is widely used in chemical plants. But its structure is complex and its maintenance is large.

W-type reciprocating vacuum pump is one of the main equipment to obtain rough vacuum. It is used to extract vacuum or other gases from closed containers or reaction pots. It is not suitable for extracting corrosive gases or gases with hard grained ash powder.

Reciprocating Vacuum Pump Structure Composition:

The structure of W-type reciprocating vacuum pump consists of two main parts.

The mechanical transmission part and gas flow part of W-type reciprocating vacuum pump. The whole structure of the mechanical transmission part is installed in a closed body, and the crankshaft is supported in tapered roller bearings on both sides of the body.

The crankshaft of the W-type reciprocating vacuum pump is equipped with a large pulley at one end to drive the transmission part. The connecting rod connects the crankshaft journal with the cross head. One end of the piston rod is rotated into the screw hole of the cross head, and the other end is installed in the cone hole of the piston and fixed by a nut.

W-type reciprocating vacuum pump motor and the small pulley mounted on the shaft drive the crankshaft to rotate through triangular tape, so that the piston can reciprocate in the cylinder through the role of connecting rod and cross head.

When the connecting rod crankshaft mechanism of W-type reciprocating vacuum pump moves in the body, the oil in the oil pool splashes to lubricate the friction surfaces of bearings, crankshaft necks, crossheads and slideways. In order to facilitate inspection and maintenance of the transmission mechanism, removable door covers are installed on both sides and behind the body, and oil windows are installed on the back cover to indicate the oil level of the oil pool in the body.

Reciprocating Vacuum Pump Application:

W-type reciprocating vacuum pump has been widely used in various industrial sectors, such as vacuum distillation, evaporation, crystallization, drying and filtration in chemical or food industry, degassing in vacuum metallurgical industry, and infiltration in electrical industry.

It is not suitable for pumping gases with excessive oxygen, explosive, corrosive to metals, chemical reactions with pump oil and particulate dust, nor for conveying gases from one container to another for conveying pumps. Therefore, the selection of chemical and pharmaceutical industries should be cautious.

Guidelines for Selection of Reciprocating Vacuum Pumps

Reciprocating vacuum pump product name and model, reciprocating vacuum pump pipe diameter, reciprocating vacuum pump using lift (m), reciprocating vacuum pump motor power (KW), reciprocating vacuum pump motor speed (r/min), reciprocating vacuum pump voltage [V], reciprocating vacuum pump using suction (m), reciprocating vacuum pump using medium name, specific gravity, viscosity, corrosiveness, corrosiveness, etc. Toxicity.

Water jet vacuum pump

Water Jet Vacuum Pump Principle and Application:

Water jet vacuum pump is a kind of mechanical device with three kinds of effective energy, such as vacuum pumping, condensation and drainage. It uses a certain pressure of water to eject symmetrically and evenly into a certain side slope.

Because of the high velocity of jet water, vacuum is generated in the chamber. In addition, because of the direct contact between secondary steam and jet water, most of the steam condenses into water. A small amount of uncooled steam and non-condensable gas also mix and extrude through the diffuser because of friction with the high-speed jet water. Excluded, so that a higher vacuum in the chamber.

Hydraulic ejector is widely used in vacuum and evaporation systems, vacuum pumping, vacuum evaporation, vacuum filtration, vacuum crystallization, drying, deodorization and other processes. It is widely needed by sugar, pharmaceutical, chemical, food, salt, monosodium glutamate, milk, fermentation and some light industry and national defense departments. But at present, the manufacturers of hydraulic ejectors are small and the varieties are not complete.

The structure of multi-nozzle and steam ring (guide plate) is adopted. As well as the use of multi-stage pump intake, low installation, improve and improve its performance, so it has a certain degree of advanced, vacuum condensation equipment is an innovation.

Water Jet Vacuum Pump Structural Advantages:

The water jet vacuum pump consists of the body, cover, nozzle, nozzle seat plate, guide plate, diffuser tube and one-way valve. The nozzle is made of stainless steel. The nozzle seat plate is processed by high quality steel. The other parts are cast iron. The nozzle adopts the structure of multiple nozzles in order to obtain a larger water-vapor contact area, which is conducive to heat exchange and obtain a better vacuum effect.

The nozzle seat plate is precisely machined and has high precision, so that the jet water can accurately gather in the same focus. The guide disc is used to slow down the flow rate of steam (or air) so that the steam is evenly introduced into the chamber to avoid the deviation of the jet flow and reduce the efficiency of pumping.

The whole device of water jet vacuum pump has compact structure and high strength. It is used in vacuum evaporation system. Because it can combine the condensation function of condenser with the pumping function of vacuum pump in one device, it greatly simplifies the process flow. Compared with the original device of vacuum pump and old condenser, it can save the equipment of vacuum air pump, condenser and water distributor. And there are the following advantages:

1. Hydraulic injection has small volume, light weight and compact structure. And the efficiency is relatively high, the power consumption is lower than the vacuum system, and the investment is low.

2. Simple operation and convenient maintenance, no need for full-time personnel to take care of

Water Jet Vacuum Pumps Types:

Jet pump is a kind of fluid action pump, which uses the energy conversion of fluid flow to achieve the conveying flow. The working fluid of the jet pump can be steam, air, water and oil. Jet vacuum pump, also known as jet vacuum pump, uses the high-speed jet of the nozzle to extract the gas from the container to obtain vacuum. It is mainly used as a vacuum pump in chemical production and widely used in evaporation and distillation process.

The working fluid of jet pump can be steam, water or other liquids or gases. The working steam is ejected at a high speed through the nozzle at high pressure. During the ejection process, the static pressure energy of the steam is converted into kinetic energy, thus creating a low pressure zone at the suction port, which sucks the conveyed fluid. After mixing the inhaled fluid with steam, it enters the enlarged tube, the flow velocity decreases gradually, and the pressure increases accordingly, and discharges from the pressure outlet.

1. Steam Jet Pump

The working medium of steam jet pump is water vapor, which is a jet vacuum pump that can directly exhaust the atmosphere.

Its working process is divided into three stages:

One is the adiabatic expansion stage, that is, the working steam expands adiabatically through the nozzle. The working steam transforms its pressure energy into velocity energy and sprays out at a high speed.

Secondly, in the mixing stage, the working steam mixes with the exhausted gas and exchanges energy between the two streams. The speed of the exhausted gas is increased, and the working steam will carry the exhausted gas into the diffuser.

Third, in the compression stage, the working steam and the pumped gas continue to exchange energy while being gradually compressed, so that kinetic energy can be converted into potential energy. When they reach the throat of the diffuser, they complete the mixing stage and make the two airflows reach the same speed. Then they are diffused to further reduce the speed and expand the pressure. Then the pumped gas is discharged from the ejector to complete the steam injection. The working process of the pump.

2. Air jet pump

The working principle of air jet pump is similar to that of steam jet pump, but its working medium is compressed air or atmospheric air. According to whether the working medium is high pressure air or atmospheric air, it can be divided into general air jet pump and atmospheric jet pump.

General air jet pumps have to be equipped with large capacity air compressors because of the large consumption of working media; general air jet pumps. Most of them are used in single stage.

Atmospheric jet pump usually works in series with one or two to three stages, and is usually installed in the inlet VI of water ring vacuum pump to form a high vacuum unit, in order to improve the limit vacuum degree and expand the working pressure range of water ring vacuum pump.

3. Water jet vacuum pump

When the vacuum requirement is not too high, a certain pressure of water can be used as the working medium of the water jet vacuum pump. The speed of water injection is usually about 15-30m/s. Although it belongs to the coarse vacuum device, it has the dual function of producing vacuum and condensation steam, so it has been widely used. The working principle of water jet vacuum pump is similar to that of steam jet pump, and its efficiency is usually less than 30%.

Jet Vacuum Pump Application:

Jet vacuum pump has the advantages of simple structure, easy manufacture, no moving parts, easy failure and low maintenance workload. It can transport fluids with high temperature, corrosiveness and solid particles. But its efficiency is low, generally about 25%-30%. In petrochemical production, jet pumps are not only used to replace mechanical vacuum pumps, but also widely used in mixers, coolers, absorbers and so on.

Jet pumps are widely used in conveying and compressing mixed gases and vapors, liquids and solids. Gases or liquids are often used as power media. Jet pump is another very important application for generating vacuum.

Jet pumps are suitable for high temperature, high pressure and high vacuum fields, such as vacuum evaporation, vacuum drying, vacuum refrigeration, vacuum distillation, lifting liquid, alkali or suspension containing abrasives, and also for special environment with strong radiation.

Jet Pump in Vacuum Generation Application:

Because of the diversity of jet pump, it has been widely used in various fields, such as chemical reactor, exhaust system, water treatment equipment, mixing tank, storage tank, waste water treatment equipment, heating system, heating gas supply system, power plant, swimming pool, salmon factory water supply, etc. And the formation of vacuum in different industrial fields.

It is an important application field to form vacuum in jet pump with steam as power medium. The high-speed jet is several times the speed of sound, so the jet pump can also easily handle large-capacity materials in vacuum.

Because the single stage jet pump can only overcome the extremely limited compression ratio, when the suction pressure is low, several jet pumps must be installed in series. The suction pressure of multi-stage steam jet vacuum pump can reach as low as 0.01 mbar. In order to condense most of the power steam and minimize the suction capacity of the next stage, a condenser is usually placed between two jet pumps. According to the application situation, direct contact condenser or surface condenser is used.

Water vapor is the main power medium in jet pump. In most industries, water vapor is produced in large quantities as a basic energy, so it is very easy to obtain. In the condensation process of power steam, wastewater will be produced more or less. Although the quantity is very small and the steam jet pump is still the most economical vacuum pump even if the discharge cost of wastewater is taken into account, it always has a negative impact on the vacuum jet pump.

As an alternative, product steam is increasingly used in the operation of jet pumps. For example, solvent vapor, chlorobenzene, toluene, butanediol, ethylene, ethylene glycol, furan.

In this case, evaporation of power steam after condensation is used as power medium. Owing to the low evaporation temperature of organic steam, in most cases, this method of operation is more conducive to saving energy than steam operation.

Another important operating range of jet pump using product steam as power medium is that water is not allowed to be mixed into process materials. In order to obtain the best efficiency, the jet pump using product steam as power medium still needs to be studied in detail.

Advantages of jet pump: As far as structure and function are concerned, this kind of jet pump is not much different from vacuum jet pump using steam as power medium, and has the same advantages: simple structure; safe and reliable operation without maintenance; long service life and wear resistance; suitable material selection can be corrosion resistant; all materials can be manufactured. In addition, due to the recycling of condensate, there is no emission pollution.

Jet vacuum pumps are used in various industrial fields. The following are several important applications.

GEA Jet Pump Company has developed combined pumps in chemical industry and has been widely used. This pump is characterized by compact shape and dual design. Two parallel pumps can operate independently and alternately or simultaneously, so they may be repaired without stopping.

In chemical industry, if stainless steel can not meet the requirements of corrosion resistance, ceramic/graphite vacuum jet pump can be used to remove corrosive gas and steam. The jet pump is made of ceramics and the surface condenser is made of graphite. Surface condenser is a compact combination of condensers. This structure has the advantages of small size, less space and simple field assembly.

In refineries, the combination of steam vacuum jet pump and liquid ring pump is used in vacuum distillation column system of refineries. The combination of the two pumps maintains very low consumption of steam, water and electricity. The steam vacuum jet pump of GEA Jet Pump Company is very suitable for this purpose because of the large amount of gas that can be transported (in the range of 104-106 m3/h). At the same time, the operation is safe and reliable, and it is not easy to break down.

Similarly, large volume flow is involved in the vacuum generation of degassing in steelmaking. In order to produce a certain quality of steel, the treatment of some raw steel needs to be carried out in vacuum. This vacuum pump must have two functions. One is to quickly empty the container to achieve the required pressure. This means that the initial suction capacity of the vacuum jet pump must be very large (thousands of kg/h). The second is to remove a large number of inert gases (about 0.6 mbar, several hundred kg/h) while maintaining low pressure.

In addition, vacuum jet pumps are also used for deodorization of edible oils, production of polymers from chemical syntheses, desalination of seawater, oil dehydration, conditioning of food, beverage and tobacco, suction of spinning baths and many other applications.

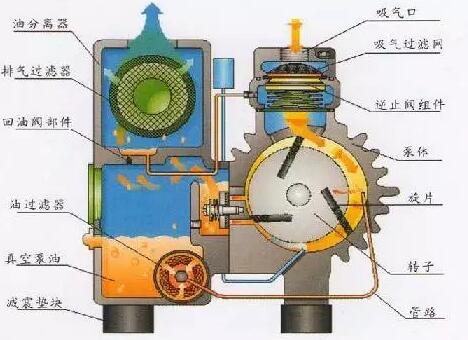

Rotary vane vacuum pump is an oil-sealed mechanical vacuum pump, which is one of the most basic vacuum acquisition equipment in vacuum technology.

Rotary vane vacuum pump can extract the dry gas from the sealed container, and a certain amount of condensable gas can also be extracted if a gas ballast device is attached. But it is not suitable for extracting gases with excessive oxygen, corrosive to metals, chemical reaction to pump oil and particulate dust. There are two kinds of single-stage rotary vane vacuum pump and double-stage vacuum pump.

rotary vane vacuum pump Structural description:

Rotary vane vacuum pump is a kind of volume pump. It sucks and compresses the gas through the continuous operation of the vane in the pump chamber, and finally discharges the gas through the exhaust port. The pump is mainly composed of stator, rotor, rotor and so on. The rotor is eccentrically loaded into the stator cavity. There are two rotating blades in the rotor slot, and the spring of the rotating blade is placed between the two rotating blades. The inlet and exhaust ports of the stator are separated by the rotor and the rotor.

When the rotor rotates in the stator chamber, under the combined action of spring tension and centrifugal force, the end of the rotor slides close to the inner wall of the pump chamber, periodically expands the volume of the chamber on the side of the air inlet and inhales the gas, gradually reduces the volume of the exhaust port, compresses the inhaled gas, and then discharges it from the exhaust port to achieve the purpose of exhaustion.

Rotary vane vacuum pump characteristics and application scope :

Rotary vane vacuum pump features:

The suction port of the vacuum pump is equipped with a coarse filter with wire mesh. It can prevent solid particles from being sucked into the pump chamber. The oil separator is equipped with an exhaust transitor with high efficiency for oil and gas separation. When the pump stops, the suction valve built in the suction port isolates the pump from the pumped system and prevents oil from returning to the pumped system. The pump is cooled by air. All pumps of XD rotary vane vacuum pump are driven by direct motor through elastic coupling.

rotary vane vacuum pump scope of application:

1. Vacuum pumps are suitable for vacuum pumping in closed systems. Such as vacuum packaging, vacuum forming, vacuum attraction.

2. Inlet pressure range: 100Pa-100000Pa. Oil mist will be generated at the outlet of the vacuum pump working beyond this range. The working environment temperature and the inhalation gas temperature of XD rotary vane vacuum pump should be between 5 ~40 C.

3. Vacuum pumps cannot pump water or other liquids. No explosive, flammable, excessive oxygen and corrosive gases can be removed.

4. Generally supplied motors are not explosion-proof. If explosion-proof or other special requirements are required, the motor must meet the relevant standards.

rotary vane vacuum pump Application :

Its working pressure range is 101325-1.33 *10-2 (Pa), which belongs to low vacuum pump. It can be used alone or as the front pump of other high vacuum pumps or ultra-high vacuum pumps. It has been widely used in metallurgy, machinery, military industry, electronics, chemical industry, light industry, petroleum, medicine and other production and scientific research departments. Rotary vane vacuum pump is one of the basic equipment for gas extraction. It can be used alone or connected with super high pumps such as booster pump, diffusion pump, molecular pump and so on.

Rotary vane vacuum pump is the basic equipment used to extract gases from a specific sealed container, so that the container can obtain a certain vacuum. Due to the high development of modern science and technology, the application of rotary vane vacuum pump is widely used in various scientific fields and various enterprises and institutions. It can be used in metallurgy, chemical industry, light industry, petroleum, medical treatment, pharmaceuticals, printing and dyeing, electrical appliances, vacuum, semiconductor, food and raw materials. Scientific research institutions such as Zineng and textile, colleges and universities, industrial and mining enterprises are used for scientific research, production and teaching. It is widely used in oil press.

Because the rotary vane vacuum pump is made of ferrous metal, and is more precise, the work of the whole pump is linked together, so the rotary vane vacuum pump is not suitable for pumping out all kinds of gases which contain too much oxygen, poisonous, explosive erosion of ferrous metal and have chemical effect on vacuum oil, nor can it be used as a compressor and delivery pump. If there is a pump with an air-ballast device, a certain amount of condensable vapor can be removed.

rotary vane vacuum pump use

Before starting, check whether the cooling water of the water-cooled pump is connected or not. When the ambient temperature is low, the pulley can be moved by hand so that the oil in the pump chamber can be discharged into the tank. Then press the motor button to send electricity, pay attention to whether the direction of power supply is reversed, and whether the direction of pump rotation is correct.

Check whether the oil quantity of the vacuum pump is near the oil mark line; do not open too fast when connecting the valve of the pumped system to prevent a large amount of fuel injection; pay attention to abnormal noise and shock during operation, pay attention to the increase of the oil temperature of the pump, stop the pump immediately when there is partial overheating, to prevent the pump from sticking or wearing. Pump shutdown must be amplified from the pump inlet (generally purchased units have automatic release valves); after power failure, water will be cut off.

rotary vane vacuum pump performance characteristics :

Rotary vane vacuum pump is a vacuum pump with periodic volume change of pump chamber separated by rotating vane to realize pumping. When working fluid is used to lubricate and fill the dead gap of pump chamber and separate exhaust valve and atmosphere, it is commonly called rotary vane vacuum pump of Schindler vacuum pump. Its performance has the following characteristics:

1. Small size, light weight and low noise;

2. An air ballast valve is provided to remove a small amount of water vapor.

3. High vacuum limit;

4. Compulsory oil feeding, full lubrication, reliable performance;

5. Double safety device for automatic oil return prevention is installed.

6. Continuous operation can be maintained at the intake pressure of 1.33 *10 Pa.

7. No oil leakage, no oil injection and no pollution to the working environment. The exhaust device has a special oil mist collector.

8. It can be equipped with small caliber transfer joint and international standard KF interface.

rotary vane vacuum pump application characteristics:

Pumping rate: 4-100L/S (liter/second)

Limit pressure: <6*10-2Pa(Pa)

Limit Vacuum: <1.3Pa (Pa)

Gas type: Clean and dry air without other mixtures at room temperature. No air containing other dust and moisture is allowed.

Requirements: When the inlet pressure is greater than 6500 Pa, continuous working time should not exceed 3 minutes to avoid pump damage caused by fuel injection.

Working requirements: The import pressure is less than 1330 pa, allowing long-term continuous work.

Ambient temperature: Vacuum pumps are generally used at room temperature of not less than 5 C and relative temperature of not more than 90%.

Piston Vacuum Pump Structural Characteristics:

Piston vacuum pump is a kind of oil seal vacuum pump commonly used in industrial field. Unlike other oil-sealed vacuum pumps, its greatest feature is that the sliding valve type rotor makes mechanical movement in the pump, and changes the volume of the cavity to achieve a specific pump mother. So piston vacuum pump is also a kind of volumetric pump. Like other oil-sealed vacuum pumps, it can also extract general gas or contain a small amount of condensable gas, which is widely used in vacuum in different fields.

Like general rotary vane vacuum pumps, piston vacuum pumps can be divided into single-stage and bipolar ones. Of course, according to their structural characteristics, there are two different structural forms, vertical and horizontal. The limit vacuum value of single-stage piston vacuum pump can be pumped to 0.4 ^-1.3 pa, and the limit pressure of double-stage piston vacuum pump can be pumped to the range of 6 X 10-2-10-‘Pa. In practical industrial applications, the single-stage sliding valve vacuum pump is usually used when the pumping speed exceeds 150L/S.

Because of its structural characteristics, the pump has the advantages of long-term working under high pressure and poor pumping conditions, long service life and so on. It has been widely used in various fields (such as vacuum smelting, vacuum drying, vacuum coating, vacuum immersion, etc.). Because the piston vacuum pump is durable and reliable, and can work in harsh pumping environment, it can be used alone or as the front pump of other vacuum pumps.

Piston vacuum pump has single-stage H-type and double-stage 2H-type. Piston vacuum pump is suitable for pumping air and other general gases. When using gas ballast, it can also suck a small amount of condensable gases (such as water vapor) in the palm.

When pumping gases containing too much oxygen, explosive, corrosive to ferrous metals and chemical reaction to vacuum oil, additional devices should be installed. This type of pump can be used alone or as the front pump of high vacuum pumps such as diffusion pump, oil booster pump and Roots pump. Compared with rotary vane vacuum pump, H type piston vacuum pump is durable and has long service life. The pump is widely used in vacuum coating, vacuum heat treatment, vacuum sintering, molecular distillation and aviation simulation test.

Piston Vacuum Pump Characteristics :

1) After optimum design, the weight has less vibration and low noise.

2) Bearing seal chamber is separated from pump chamber by oil supply alone, which avoids impurities entering bearing and premature damage of seal.

3) According to user’s requirement, auxiliary oil tank can be attached to achieve the function of cooling vacuum oil to separate impurities.

4) Except for the old H-150, the motors are placed above the pump with compact structure and less floor area.

Piston Vacuum Pump Application Range:

It is widely used in aerospace, aviation, atomic, petroleum, chemical, pharmaceutical, electrical, ceramics, smelting, new materials, vacuum heat treatment, vacuum coating and other industries. The sliding valve vacuum unit has remarkable energy-saving effect, high vacuum degree and large pumping capacity in high vacuum interval. It can be widely used in vacuum impregnation and vacuum drying of transformers, wires, cables and capacitors in power industry.

It is an ideal vacuum equipment for vacuum coating, vacuum smelting, vacuum heat treatment, vacuum oil filtration, freeze-drying and aviation simulation test. If a small amount of water vapor or dust is sucked, a filter device should be installed.

Key Points of Application of Piston Vacuum Pump

Piston vacuum pump is an old pump, but compared with rotary vane pump, it has the outstanding advantages of allowing high working pressure (104Pa), large pumping capacity, continuous working in harsh environment and durability, so it has been widely used in vacuum smelting, vacuum drying, vacuum impregnation, vacuum distillation and other industries. With the increasing application of vacuum, it has been widely used in vacuum drying, vacuum distillation and other industries. In vacuum impregnation, vacuum dehydration, vacuum smelting and other industries, there is a large amount of water vapor in the gas pumped by sliding valve pumps.

If the vacuum pump can not be eliminated in time, it will pollute the vacuum pump oil, resulting in a reduction in the pumping performance of the vacuum pump. Although a gas ballast valve is installed on the pump to approve reducing the limit vacuum of the pump and extracting condensable gas by gas ballast method, the gas ballast method is not ideal for vacuum drying, dehydration, sludge refining and other processes with high water vapor content. Generally, the following methods can be tried out:

A piston vacuum pump and condenser are used together. At present, most domestic manufacturers adopt this scheme. The principle is to connect the condenser in series between the pump and the pumped container, and capture a large amount of water vapor in the vacuum process equipment into water with the condenser, so as to reduce the amount of water vapor entering the vacuum pump and reduce the pollution degree of pump oil. If the flow rate of the condenser outlet valve is properly adjusted and the ballast valve on the vacuum pump is brought into full play, better pumping effect can be achieved.

B Change piston vacuum pump to heat pump. According to the physical characteristics of water and the principle of phase diagram, the sliding valve vacuum pump can be changed into heat pump. In this way, a large amount of condensable water vapor can be pumped out at higher pump chamber temperature. Its working principle is as follows: a set of automatic temperature control controller is used to control the temperature of the pump chamber by automatically controlling the cooling water flow of the pump. In the process of pumping, the temperature of the pump chamber is always controlled at a temperature higher than the saturated vapor pressure of water, which makes a large amount of vapor in the pumped gas be discharged smoothly.

In order to avoid the phenomena of thinning of pump oil, decreasing of vacuum degree and stuck operation parts due to high temperature in pump chamber, high temperature resistant pump oil (N-62 or N-68) and high temperature resistant bearing can be used in design, and the clearance of operation parts can be increased.

Roots Vacuum Pump Structure :

1. General structure of pump

The layout of the pump body of Roots vacuum pump determines the overall structure of the pump. At present, there are roughly three types of Roots vacuum pumps at home and abroad:

Vertical structure of the intake and exhaust port level settings, assembly and connection pipelines are more convenient. But the center of gravity of the pump is high and its stability is poor at high speed, so this type of pump is mostly used in small pumps.

Horizontal pump intake is in the upper, exhaust is in the lower. Sometimes in order to facilitate the installation and connection of the vacuum system pipeline, the exhaust outlet can be connected from the horizontal direction, that is, the direction of intake and exhaust is mutually perpendicular. At this time, the exhaust outlet can be opened in both left and right directions. In addition to one end of the exhaust pipe, the other end is blocked or connected with a bypass valve. The pump has low center of gravity and good stability at high speed. Generally large and medium-sized pumps use this structure.

The two rotor shafts of the pump are installed vertically with the horizontal plane. The assembly clearance of the structure is easy to control, the assembly of the rotor is convenient, and the area of the pump is small. But the center of gravity of the pump is high and the gear disassembly and assembly is inconvenient, and the lubrication mechanism is relatively complex. It is only found in foreign products.

2. Driving mode of pump

The two rotors of Roots vacuum pump are synchronized by a pair of high precision gears. The drive shaft is connected with the motor through a coupling. There are two main types of transmission structure arrangement:

One is that the motor and the gear are placed on the same side of the rotor as shown in the figure. The driven rotor is driven directly by the end gear of the motor, so that the torsional deformation of the active rotor shaft is small, and the clearance between the two rotors will not change because of the torsional deformation of the active shaft, so that the clearance between the rotors is uniform in the course of operation.

The biggest disadvantage of this transmission mode is: a. There are three bearings on the drive shaft, which increases the difficulty of processing and assembling the pump, and the disassembly and adjustment of the gears are inconvenient; B. The overall structure is not symmetrical, and the center of gravity of the pump is biased to the side of the motor and gear box.

The other is that the motor and the transmission gear are installed on both sides of the rotor respectively. This form makes the overall structure of the pump symmetrical, but the torsional deformation of the driving shaft is large. In order to ensure that the clearance of the rotor is uniform in the process of operation, it is required that the shaft should have sufficient stiffness and the connection between the shaft and the rotor should be tightened (at present, the rotor and the shaft are welded or cast into one structure). This kind of structure is very convenient to disassemble and assemble, so it is widely used.

Roots Vacuum Pump Characteristics:

Quick start-up, low power consumption, low operating protection cost, high pumping speed, high efficiency, insensitive to a large number of water vapor and dust contained in the exhausted gas, large pumping rate in the pressure scale of 100-1 Pa, can quickly eliminate sudden gas release.

This pressure scale is just between the oil-sealed mechanical vacuum pump and the decentralized pump. Therefore, it is often connected in series between the distributed pump and the oil-sealed mechanical vacuum pump to improve the pumping capacity of the pressure scale at both ends. At this time it is also called mechanical booster pump.

1. Large pumping speed in a wide pressure range;

2. The rotor has good geometric symmetry, so it has small vibration and runs bumpy. There are clearances between the rotors and between the rotors and the shells, which do not need to be smooth, and the friction loss is small. The driving power can be greatly reduced, so that the higher speed can be achieved.

3. There is no need for oil sealing and smoothness in the pump chamber, which can increase the purification of the vacuum system by oil vapor.

4. There is no contraction and no exhaust valve in the pump chamber. The structure is simple and compact, and insensitive to dust and water vapor in the exhausted gas.

5. The contraction ratio is low and the consequence of hydrogen extraction is poor.

Roots Vacuum Pump Application:

Roots vacuum pump has been tested by long-term operation in petroleum, chemical industry, plastics, pesticides, steam turbine rotor dynamic balance, aerospace space simulation and other devices, so it should be vigorously promoted and applied in China.

At the same time, Roots vacuum pump is widely used in vacuum metallurgy smelting, degassing, rolling, as well as in food, pharmaceutical industry, vacuum distillation, vacuum concentration and vacuum drying. Vacuum pump accessories for noise control of vacuum pump, vacuum pump muffler.

The appearance of the rotor is a complex curved cylinder, which is difficult to process and review. Roots pump has been developed rapidly at home and abroad in recent years. It has been widely used in smelting, petrochemical, electrical and electronic industries.

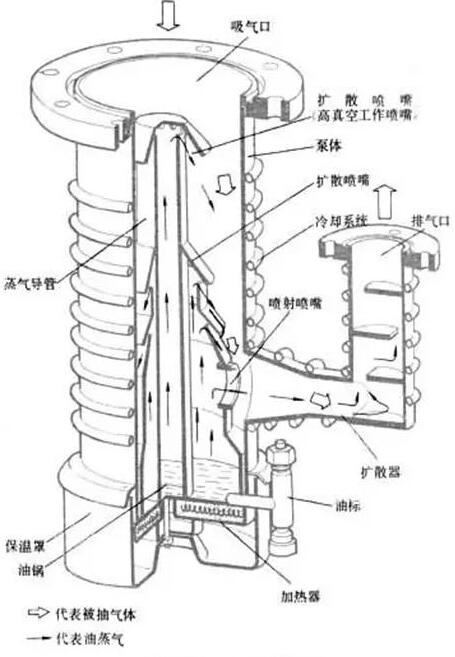

diffusion pump performance parameters :

Usually, the performance of diffusion pump depends on the limit vacuum, maximum back pressure, pumping rate and setting of cold trap or low temperature baffle.

1. Limit vacuum

If the structure of general oil diffusion pump is improved, such as reducing the reflux of oil vapor, adding a pick-up device, rationally distributing heating power, improving the design of nozzle angle, adding oil cap, baffle or cold trap, adsorption trap, etc., the performance of the diffusion pump can be greatly improved, and the ultimate vacuum can achieve lower pressure.

2. Maximum Backpressure

The maximum back pressure is the maximum allowable pre-pressure of the diffusion pump. If the pressure produced by the front pump is higher than the maximum back pressure, the diffusion pump will not work properly.

3. Pumping rate

The pumping speed of diffusion pump can be calculated according to the theory of gas molecule motion.

4. Reasons for setting cold traps and low temperature baffles

Because of the oil vapor molecule ejected from the nozzle of the diffusion pump, most of it is condensed by the pump wall, which is due to the installation of cooling water jacket or cooling pipe outside the pump wall. However, a small number of vapor molecules are reflected by the pump wall, and scattering will return to the pumped space. This phenomenon should be paid special attention in low temperature laboratories.

If a cold trap or a low temperature baffle is added before the diffusion pump and the pumped container, the back-added vapor can be condensed and the back-flow of oil vapor can be cut off.

Diffusion Pump Application Range:

The working principle of diffusion pump is similar to that of steam jet pump. Both of them use high-speed steam jet to carry gas in order to achieve the purpose of pumping. Therefore, diffusion pump has similar characteristics with steam jet pump.

The main difference is that the diffusion pump works in the high vacuum region, and its working pressure ranges from 10-2 to 10-6 PA. Diffusion pumps are widely used in electronic, chemical, metallurgical, mechanical, petroleum and atomic energy industries.

diffusion pump Influencing factors:

1. Reflux of oil diffusion pump.

2. Reverse diffusion of gas molecules.

3. Diffusion pump oil cracking decomposition, the general diffusion pump to its working oil requirements are saturated vapor pressure (at room temperature about 0.00000001Pa), good thermal stability, not easy to be oxidized, high molecular weight of high boiling point liquid, such as silicone oil is the ideal working oil in the diffusion pump.

4. Pump cleaning is not clean, pollutants remain in the pump and recycle repeatedly, affecting its vacuum.

Diffusion pump is a kind of secondary pump. It needs mechanical pump. At present, diffusion pump is one of the most widely used and main tools to obtain high vacuum. As the front pump. High vacuum diffusion pump is mainly composed of pump body, cooling cap, nozzle, steam guide pipe, heater and cooler.

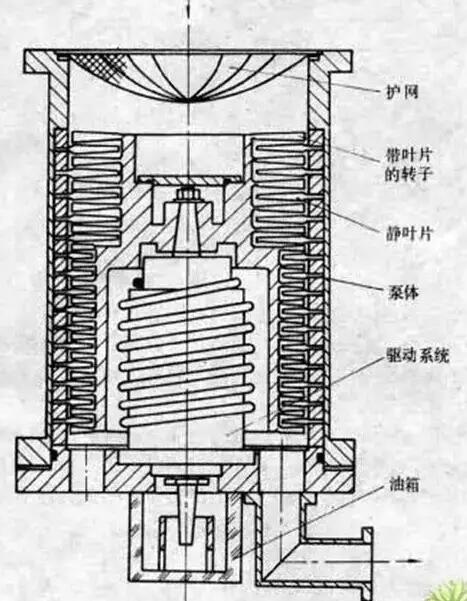

Molecular pump is a kind of vacuum pump which transfers momentum to gas molecule by high-speed rotating rotor to obtain directional velocity, and then is compressed and driven to the exhaust port and pumped out for the front stage. Because the groove of the profile of the simple traction pump is located on the outer surface of the rotor cylinder or the inner surface of the pump, it can make full use of the higher linear velocity of the outer cylinder to transfer momentum of the gas molecule and improve the pumping effect of the pump.

Because the turbine stage has a large extraction area and a large extraction speed, and the traction stage has a small groove extraction area, the flow pattern of gas molecules compressed by the turbine blade suddenly changes at the junction of the two structures, which makes the movement of gas molecules change from orderly to disorderly at the junction, and then makes the reflux increase and the extraction capacity decrease.

Molecular Pumps Working Conditions :

1. Rotor speed reaches 20000r/min, so the start-up time of molecular pump is longer.

2. Gas is in the state of molecular flow, so it needs to be equipped with a front-stage pump, which usually uses a rotary vane pump as the front-stage pump.

Molecular Pumps Characteristics:

Oil Lubricated Molecular Pump: Small amount of lubricating oil, and in the front vacuum section, less pollution to the vacuum chamber.

Grease Lubricated Molecular Pump: The amount of grease is very small, and the clean vacuum without oil can be obtained by the front graded dry pump.

All-Magnetically Suspended Molecular Pump: Without lubrication, it can be used with dry pump to obtain a clean vacuum environment without oil.

Other Common Applications of Molecular Pumps

1. Analysis (Mass Spectrometry, Electron Microscopy, etc.)

2. Semiconductors (electronic components, integrated circuits, flexible solar cells, etc.)

3. Optical/glass (thermal protection, antireflective, reflective, optical filter)

4. Coating (surface protection, decorative paint, display, screen)

5. Vacuum metallurgy (vacuum furnace, vacuum brazing, vacuum sintering, vacuum alloys,)

6. Leak Detection (Vacuum System, Vehicle Fuel Tank, Safety Air Bag)

7. Research experiments (medical magnetic resonance imaging, nuclear particle physics, nuclear fusion research, laser applications and many more)

8. Lamp production industry and related

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)