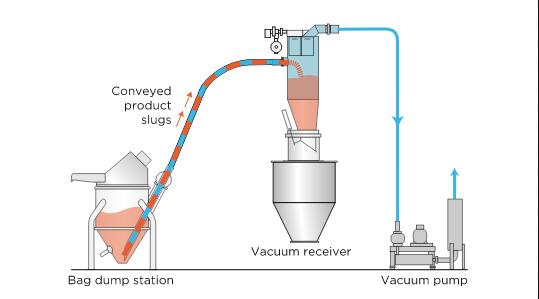

Vacuum suction pneumatic conveying system

In the dilute medium and low vacuum suction pneumatic conveying system, the air in the suction system of the new negative pressure roots vacuum pump installed at the end of the conveying system and the negative pressure air flow below the atmospheric pressure are formed in the conveying pipe. The material enters the pipe from the starting suction nozzle together with the atmosphere. As the air flow is transmitted to the end separator, the material particles are separated from the air flow by gravity or centrifugal force The dust remover is separated and the gas is discharged into the atmosphere through the silencer at the outlet of the negative pressure roots vacuum pump after dust removal.

vacuum suction pneumatic conveying system characteristics:

This system is a kind of negative pressure pneumatic conveying system, which uses the new negative pressure roots vacuum pump as the vacuum air source and continuously sucks and delivers materials. The system has the advantages of centralized conveying of granular materials from several places to one place; low conveying pressure, reliable conveying and simple equipment; because the pressure in the system is lower than the atmospheric pressure, the transported materials will not escape from the system; because the suction nozzle sucks materials, the dust flying at the sampling point can be avoided and the production efficiency is high. Vacuum conveying is the first successful way to transport light materials in industry. Such as: tobacco, tea, fiber materials, and later developed to transport grain and warehouse, port for powder, granular material loading and unloading operations. At present, it is also used to transport molding sand (including new sand, old sand, clay particles), coal powder and mineral sand in the foundry workshop. Its application has almost spread across all industrial sectors, and it has been increasingly developed in transportation, building materials, machinery, chemical industry, agriculture, electricity, metallurgy, mining, casting, food, paper, pharmaceutical and other industrial sectors.

vacuum suction pneumatic conveying system introduction:

The dilute medium and low vacuum suction pneumatic conveying system has the following characteristics:

1. The equipment is simple in structure, convenient in manufacture, processing and installation, less in control cost and short in construction time. The main component of the vacuum conveying system is the welding structure of section steel plate, which is composed of the components with the shape of pipe and tank. There is no relative movement between the components, and the maintenance operation is relatively easy. If some control equipment is added, it is easy to realize the automatic operation.

2. High transportation efficiency, no return transportation of equipment. Other transportation processes have the disadvantage of air return, and the transportation medium of vacuum transportation is air, which only needs to be emptied after the terminal dedusting. In the transportation process, the feed port can continuously feed to realize continuous transportation.

3. It is beneficial to realize bulk transportation, save packaging materials and transportation cost. Taking the transportation of cement or fly ash as an example, pneumatic bulk transportation was adopted, and the paper bags were cancelled, so that the cost per ton was reduced by 16 yuan, accounting for 15% of its value. In the process of transportation, the average loss was 2-3% because the paper bags were easy to be damaged or not clean, and the vacuum transportation could be reduced to less than 1%.

4. The working and sanitary conditions are good. During the vacuum transportation, the materials run in the pipe, which is under the negtive pressure. The dust will not escape and fly, and the materials will not fly away and pollute the environment.

5. In the process of transportation, only separation, drying and other intermediate treatment can be carried out. For example, if the material is transported under negative pressure, the figure shows that the water is easy to evaporate under negative pressure. Therefore, even if other drying methods are not used, the material with higher water content will get certain drying effect in the transportation process. According to the different particle characteristics of the material, the proper discharge port can be designed to separate the material.

6. It can transport heated materials and play a cooling role in the conveying process. For example, the hot sand in the foundry workshop does not need to be transported after being cooled, so as to shorten the working cycle.

In addition, the vacuum transmission pipeline is convenient to set up the pipe network according to local conditions. The layout is simple and flexible. It can make full use of the workshop area and adapt to the workshop environment.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)