Vacuum system for building drainage

In recent years, China’s urban domestic water consumption has increased year by year, so it is very important to use water for building construction. Therefore, it is necessary to choose a good vacuum system, and the application of building drainage is worthy of attention.

The application of vacuum system in building drainage belongs to the field of environmental protection equipment for drainage and sewage treatment. The vacuum pumping station system and toilet control system are not two independent systems in the current control system for building drainage system. The two systems share a vacuum detection switch. The system is operated and stopped by the same vacuum detection switch. Constant value control, once the vacuum detection switch fails, both systems will be disabled.

Vacuum pump and sewage pump are very useful in vacuum pumping station system. The standby pump is activated only if the current pump fails. Frequent start-up often shortens the life of the active pump. The parameter setting value of control module (such as toilet seat) in bathroom control system is fixed and cannot be modified, so it can not be used flexibly in every situation of the system.

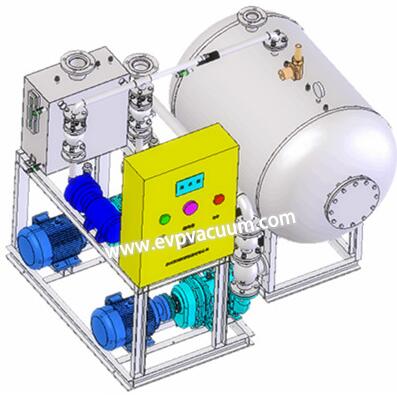

The purpose of this paper is to solve the problem that the vacuum pump and sewage pump in the existing building drainage system control device are not used correctly, the toilet seat and other control modules can not set and modify the parameters, and can not be displayed. It is used to confirm the fault of control modules such as toilet seat. In order to achieve the above purpose, technicians use a technical scheme of vacuum system to construct a vacuum drainage device of a building. The building includes a toilet control system, which is connected with the vacuum pumping system through a sewage pipe.

The vacuum system uses the vacuum pump to pump the air in the real empty box and pipe network, so that the pipe network can maintain a relative vacuum of 0.035 ~ 0.045 MPa for a long time, and the sewage discharge is rapid. It is sucked into the vacuum pipe through the pressure difference, and then enters the vacuum collector (tank); the sewage entering the collector (tank) can be discharged into the nearby gravity drainage network or sewage treatment plant, or can be transported to the equipment in the ecological sanitation.

The main vacuum pump of the system is started to work until the vacuum level of the vacuum tank reaches the upper limit set. The vacuum pump automatically stops running, and the vacuum automatically cuts off the check valve on the pipeline in the central vacuum system. If the vacuum in the vacuum tank decreases due to the need of work and is lower than the lower limit set, the standby vacuum pump unit will automatically start. Through this cycle, the vacuum of the vacuum system can maintain a stable vacuum source and meet the production requirements.

Compared with the traditional vacuum system, this vacuum system has more obvious economic, ecological and social benefits.

People’s living standard has been greatly improved, but it puts forward higher requirements for green environmental protection. The establishment of comfortable environment, comfortable living and working environment has become the focus of urban development. The demand of human life is promoting the development of science and technology. The vacuum system, which has many advantages such as environmental protection and water saving, gets rid of the limitation of gravity gradient of drainage in the history of construction, makes the pipeline laying more flexible and is favored by users.