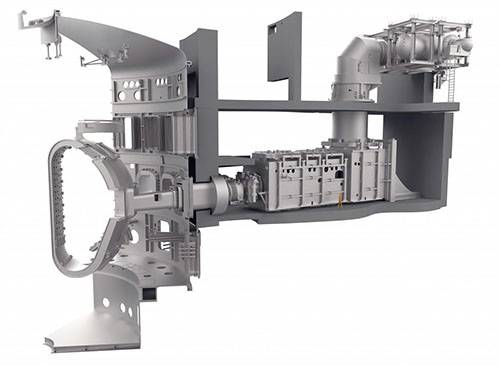

vacuum system in neutral beam injector

In neutral beam injector, the performance of vacuum system has great influence on beam transmission efficiency, service life and safety of related components in the whole beam line. Neutral beam injector (NBI) is a set of equipment that generates high-energy neutral particle beam and transports it to fusion device. Vacuum system is an important subsystem of NBI.

Neutral beam injection heating has always been a core topic in fusion research. It involves plasma physics, control, vacuum and other disciplines. Its development is closely related to the development of these disciplines. As far as the vacuum technology is concerned, the performance of the vacuum pump system is related to the beam transmission efficiency and the service life and safety of other components in the whole beam line.

Requirements of neutral beam injector for vacuum pump system:

It consists of ion source, accelerating electrode, neutralization chamber, deflecting magnet, ion eliminator, drift tube, power measuring target and several restricted orifice plates. The ion generated by the ion source is accelerated by the accelerating electrode to form high energy ion beam, which can be neutralized into high energy neutral particle beam in the neutralization chamber. At present, one of the methods to neutralize high-energy ion beams is to neutralize the high-energy ion (h *) by colliding with the gas target molecule (H2) in the neutralization chamber to generate charge exchange. The thickness of gas target is the key factor affecting the neutralization efficiency. In order to obtain the best neutralization efficiency, the pressure in the neutralization chamber should be maintained at the order of 10-4Pa. The specific size can be adjusted by the intake system according to the changes of beam parameters in the experiment. In the drift section of neutral particles, theoretically, the lower the pressure is, the smaller the loss of beam will be. However, considering that the pressure should match the pressure in the fusion device, the drift section pressure is usually selected to be one order of magnitude lower than the dynamic pressure in the fusion device, and the drift section pressure should be maintained in the order of 10-4Pa.

The application of vacuum system in neutral beam injector has many advantages

① When a vacuum source is needed, the required vacuum degree can be achieved in a very short time.

② The vacuum source is more stable and sufficient.

③ One system can be used by multiple worktables at the same time without affecting the operation of different units.

④ When the vacuum source stored in the pressure vessel is sufficient, the vacuum pump can stop working / stop operation in turn, so as to prolong the rest time of the pump, so as to reduce the loss of pump, parts and oil, reduce the operation and maintenance costs, and reduce the noise in the workplace.

⑤ It is easy to operate and master.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)