oil sealed rotary screw vacuum pumps

Oil seal rotary screw vacuum pump, also known as GV, combines powerful oil seal rotary screw technology with advanced screw design.

GV oil seal rotary screw vacuum pump combines oil seal rotary screw technology and advanced screw design. These systems operate in a pressure range from 1 to 500 mbar. The two screw elements rotate at low speeds, so the GV operates at sound levels as low as 69 DBA. The technology has no contract, so there is no wear and tear. GV is equipped with super large motor and efficient oil mist separation device. The state-of-the-art coalescence filter reduces oil mist residue in the environment, thereby reducing the amount of oil, lowering the operating temperature and reducing the power consumption of the motor.

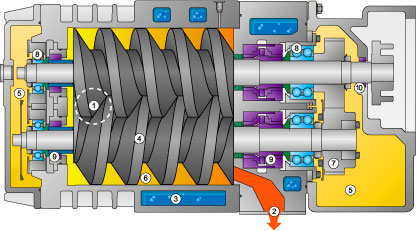

Oil seal rotary screw vacuum pump structure description:

As shown in the structural drawing of oil seal rotary screw vacuum pump, the key components of the pump are as follows:

1. Screw rotor: the screw rotor of the pump is made of high-performance nodular cast iron. After strict heat treatment, it is processed by high-precision CNC machine tool to ensure the high-precision requirements of screw profile. The screw processing accuracy is the key to ensure the performance of the whole machine. The screw must undergo high precision dynamic balance test. The screw with special requirements is also covered with wear-resistant and corrosion-resistant coatings.

2. Synchronous gear: synchronous gear is an important part of screw vacuum pump. In addition to providing sufficient torque for driven screw, synchronous gear also ensures that the meshing surface of two counter rotating screws always keeps a certain gap and never rubs. The surface of the gear is quenched by high frequency and ground and polished by high precision gear grinding machine, so as to ensure low noise, low temperature rise and stable operation of the pump.

3. Bearing: the fixed end of the pump adopts double row angular contact ball bearing, and the movable end adopts roller bearing with high load capacity. In this way, the high speed and heavy load of the pump can be ensured. Besides the clearance between gears and screws, the pump can run smoothly, with lower noise and lower temperature rise.

4. Shaft seal: the inner shaft seal of screw pump adopts two-way lip seal, which can effectively prevent the two-way mutual flow of medium and keep the medium from being polluted. The seal at the shaft outlet of the driving shaft is sealed by skeleton oil seal.

5. Oil level mirror: the normal height of oil level of gearbox is 1 / 2 of the height of mirror window. If the oil level is too low, gears and bearings will be damaged due to lack of proper lubricating oil. The minimum oil level shall not be lower than 1 / 4 height of the mirror window. Before starting the pump, the height of the oil and whether the oil is contaminated must be checked. Otherwise, the oil should be replenished or replaced with new oil. The lubricating oil lubricates and cools the bearing and shaft seal by means of high-speed rotating synchronous gear splash.

Oil seal rotary screw vacuum pump features:

Efficient field vacuum

The oil sealed rotary screw system adopts efficient vacuum technology, and its operating pressure range is 1 mbar (a) to 500 mbar (a). Its two screw assemblies rotate at low speeds so that the GV can operate at sound levels as low as 69 dB (a). This silent operation allows you to install the GV near the point of use.

Reliable Performance

Reliability is a key feature of GV vacuum system. The technology used has no contact, so there is no wear. As an added advantage, oil seal technology brings strong trouble free operation. In addition to this advanced technology, GV is equipped with reliable extra large motor and efficient oil-gas separation system. The coalescing filter reduces the amount of oil mist in the environment, thus reducing the amount of additional fuel, reducing the operating temperature and engine power consumption.

Oil sealed rotary screw vacuum pump advantages:

Maximum efficiency: GV outperforms all other vacuum technologies in its operating pressure range due to the highest performance output per kilowatt input.

Configuration capability according to requirement: the modular valve is directly installed on the pump inlet.

Plug and play installation.

The use of lifting cover instead of swing door, so space saving.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)