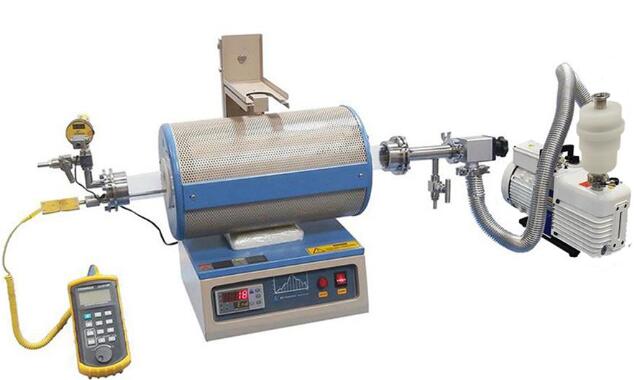

Vacuum system of vacuum tube furnace

The vacuum tube furnace is no longer unfamiliar. The basic style is cycle operation. Usually industrial and mining enterprises, laboratories, scientific research institutions, etc. use vacuum tube furnaces for heating of small steel parts such as quenching, annealing and tempering.

As the name implies, the vacuum tube furnace cannot be lacking a vacuum system. The vacuum system of a general vacuum tube furnace should be equipped with: quickly extract the vacuum degree of the vacuum tube furnace to the specified requirements, and promptly eliminate all the parts released by the processed workpieces and furnace components. There are three requirements for this kind of gas, and the vacuum unit has a small footprint, safe and reliable operation, and easy operation.

Because there are many types of vacuum tube furnaces, and each has different requirements for the vacuum system of vacuum tube furnaces, we have three systems, low vacuum, medium vacuum, and high vacuum in terms of vacuum degree. Let’s talk about the difference between these three vacuum systems in detail below.

1. Low vacuum system

The low vacuum system of the vacuum tube furnace is suitable for vacuum tube furnaces with a vacuum degree in the range of 2-1333Pa, such as pre-evacuated low vacuum pit furnaces, mostly oil-sealed rotary mechanical pumps.

2. Medium vacuum system

The medium vacuum system is suitable for vacuum tube furnaces with a vacuum degree in the range of 3×10—1.333Pa. The medium vacuum system is widely used in vacuum tube furnaces and usually consists of a two-stage vacuum pump unit. The primary pump is mostly a rotary mechanical pump or a sliding valve mechanical pump, and the main pump is a mechanical booster pump or an oil booster pump.

3.High vacuum system

The high vacuum system is suitable for vacuum tube furnaces with a vacuum degree of 6.6×10—1.333x10Pa, such as vacuum annealing furnaces and vacuum brazing furnaces. Usually composed of a three-stage vacuum pump unit, the main pump usually uses an oil diffusion pump, an ion pump, and the primary pump is mostly a rotating machinery or a sliding valve mechanical pump.

Do you know the vacuum system of vacuum tube furnace? You can make a reference, and then choose a suitable vacuum system according to your needs.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)