Vacuum System unit used in transformer vacuum drying process

Since the invention of the power transformer in the late 19th century, with the rapid development of the power industry, the power transformer is widely used as a commonly used power equipment in industrial production and daily life. The power transformer is mainly composed of iron core, coil and insulation material. After the transformer body is assembled, it needs to be dried and injected with transformer oil, so that the moisture and gas in the insulation material can be removed, and the water content can also be Controlled within the range of product quality requirements, increase the dielectric strength of the transformer and the service life of the product. In particular, the moisture content of the insulating material inside the high-voltage transformer should be controlled within 0.5%.

In the manufacturing process of transformers, vacuum drying is an important manufacturing process. It refers to the process of removing moisture and air from the body under vacuum, drying, and then performing general assembly and oil injection. By drying, a higher dielectric strength is obtained.

It can be said that the transformer drying process plays a decisive role in the performance and life of the transformer. Then in the transformer manufacturing, drying is a very critical step. At present, the commonly used transformer drying processes mainly include circulating hot air vacuum drying, circulating hot oil drying, pressure-variable valve vacuum drying, and kerosene gas phase drying.Compared with the first three, the kerosene gas phase drying process has uniform heating, fast heating speed, and good drying effect. And other advantages, widely used in the drying process of transformers.

The kerosene gas-phase drying process refers to the use of special kerosene as a heat-carrying medium to heat the kerosene in a vacuum environment. Since the specific heat capacity of kerosene is lower than that of water, the saturated steam pressure is between water and the transformer. Therefore, kerosene is easily volatilized after being heated. At the same time, the residual water in the transformer is taken away. After drying, all the kerosene in the transformer is evaporated after heating, and there is almost no residue in the transformer, which will not affect the transformer’s normal work. In addition, kerosene is also an excellent detergent. While taking away water, it can also bring dust, particles, impurities, etc. out of the transformer together, clean the transformer, improve the overall performance of the transformer, and thus improve the transformer Work efficiency.

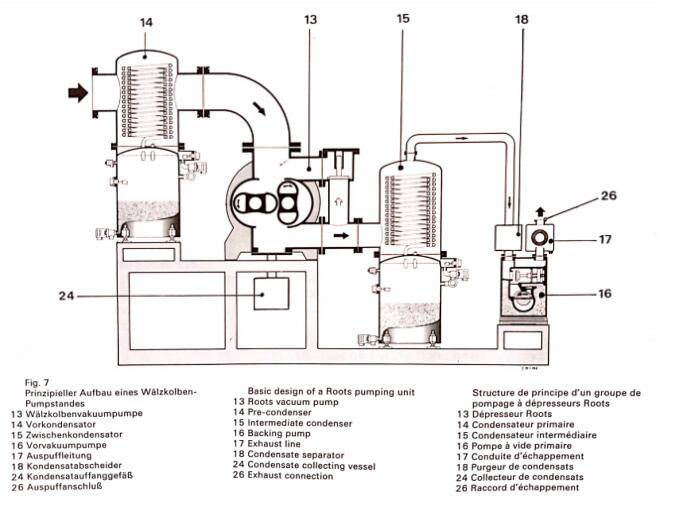

A good and stable vacuum environment plays a decisive factor in the success of the kerosene gas-phase drying process. The following figure is a flow chart of a typical vacuum system of kerosene gas phase drying process. The whole system consists of the front stage pump Part 16 (oil seal rotary vane pump), the intermediate condenser Part 15, the main pump (Roots booster pump) part 13, and the front condenser Part 14. The whole system is provided by the roots pump with high vacuum and pumping speed, the main function of the condenser is to condense the kerosene in the pumped gas to prevent it from being pumped into the pump and contaminating the vacuum pump. Especially for rotary vane pumps, pay attention to this.

EVP is a professional manufacturer of vacuum pumps, vacuum units and vacuum accessories. EVP have accumulated a lot of experience in the vacuum drying process of transformers. EVP’s Roots vacuum system has a reasonable ratio, stable performance, and less maintenance. It is the best choice for transformer vacuum drying industry. Two more classic configurations, one is the vacuum unit JZPH1200-8, which is composed of a Roots pump ZJP-1200 and a piston vacuum pump H-150, as shown below:

Another configuration is the vacuum unit JZPSV1200-6, the main pump is a Roots pump ZJP-1200, and the backing pump is an SV-630 ( air-cooled and water-cooled two versions)

Edited by: Lany SHEN; Copyright: EVP Vacuum Pump

Related products: Roots Rotary Piston Vacuum Equipment, Roots Rotary Vane Vacuum System

Application: Electric Power, Power Transformer

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)