Vacuum technology used for food freeze drying

In recent years, with the innovation of science and technology and the industrialization of food processing, people’s life rhythm has been accelerating, and the time invested in cooking has been decreasing. At the same time, with the improvement of living standards and changes in consumption concepts, people’s pursuit of food tends to be more green, convenient and nutritious. A few days ago, there are some problems with convenience foods, including the incomplete variety of convenience foods; meat staple foods are mostly fried and puffed, while the market share of convenience foods for Chinese dishes is small and the production technology is not perfect. The rise of freeze-drying technology can well meet people’s needs for green, convenience and nutrition.

Vacuum freeze-drying technology is a new type of drying method that freezes water-containing materials into solids and uses the sublimation performance of water under low temperature and low pressure conditions to dehydrate the materials at low temperatures to achieve drying. Because the vacuum freeze-drying technology is carried out in a low-temperature and low-oxygen environment, most biological reactions are stagnant, and there is no liquid water in the treatment process, and the water is directly sublimated in a solid state, so that the original structure and shape of the material are protected to the greatest extent, and the appearance is finally obtained. High-quality dry products with intrinsic quality.

At present, the vacuum freeze-drying technology has been widely used in many fields, especially the use of this technology in food processing to obtain high-quality dehydrated food.

Water has three phases: solid, liquid and gas. According to the theory of phase equilibrium in thermodynamics, as the pressure decreases, the freezing point of water does not change much, but the boiling point is getting lower and lower, approaching the freezing point. When the pressure drops to a certain degree of vacuum, the boiling point of water and the freezing point coincide, and the ice can be directly vaporized into a gas without passing through the liquid state. This process is called sublimation. The vacuum freeze-drying of food is below the triple point of water, that is, under low temperature and low pressure conditions, the frozen water in the food is sublimated and removed.

So, what is the vacuum freeze-drying process?

Pre-treatment: The source and application of raw materials are different, and the pre-treatment methods are also different. For example, the pretreatment of fruits is to select, clean and cut them, vegetables need to be blanched, and instant porridges need to be steamed and plated.

Pre-freezing: Generally, the raw materials are pre-frozen after pretreatment. This is due to the fact that if there is a lot of moisture inside the material, if the vacuum treatment is performed directly, the gas dissolved in the water will escape due to the reduction of the external pressure, forming bubbles, which will cause voids inside and on the surface of the raw material, affecting the sensory quality.

Quick freezing: In order to solidify the moisture inside the material, it is usually necessary to perform quick freezing. The shorter the freezing time, the faster the material freezes, the smaller its internal crystallization, and the less the mechanical damage to the material cells. Therefore, it is necessary to select an appropriate freezing speed according to actual production.

Vacuum drying: Vacuum drying is usually divided into two stages: sublimation drying and analytical drying. Sublimation drying is mainly aimed at the free water in the material; analytical drying is mainly to remove the adsorbed water that is strongly bound to the solid. The vacuum, temperature and thickness of the tray during the drying process directly affect the drying process and product quality.

In the entire vacuum freezing process, the choice of vacuum pump is particularly important. High-quality vacuum pumps allow foods to freeze-dry faster and better while maintaining nutrients. So, how should the vacuum pump be selected in this process? The user can flexibly select the vacuum pump according to the required pumping volume/budget, etc.

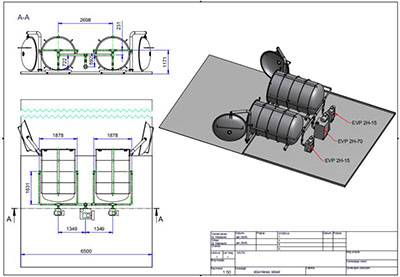

The vacuum pump provided by Shanghai EVP Vacuum Technology Co., Ltd. can meet the needs of different models/different sizes of freeze dryers. Among the several vacuum pumps that are selling well are:

1. Sliding valve type vacuum pump, the ultimate vacuum of the single-stage pump is 1Pa, and the gas volume is 70~300 L/s; the ultimate vacuum of the two-stage pump is 0.06Pa, and the gas volume is 15~150 L/s.

2. Oil-free dry scroll vacuum pump, water-free and oil-free, compact and easy to operate, is the first choice for small freeze dryer. The ultimate vacuum is below 10Pa, 2~16 L/s.

3. Oil-free dry screw vacuum pumps, screw pumps can not meet the requirements, but still want to use dry pumps, screw pumps are a good choice. Ultimate vacuum 0.01 Pa, gas volume 50 ~ 300 L/s.

4. Oil-sealed rotary vane pump. This rotary vane pump needs oil as working fluid. You can choose this type of vacuum pump when the customer budget is limited. Ultimate vacuum 1 Pa, gas volume 1 ~ 25 L/s.

EVP Vacuum has extensive experience in the freeze-drying industry, please feel free to communicate any questions.

Edited by: Emily Fu; Copyright: EVP Vacuum Solutions

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)