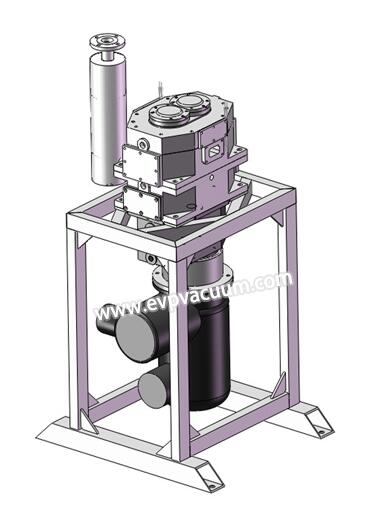

Vertical dry screw vacuum pump

The vertical dry-type screw vacuum pump, after years of dedicated research by the team, has broken through various technical difficulties on the basis of combining the most advanced international technology and process application. It is the real vertical dry screw vacuum pump at present.

Vertical dry screw vacuum pump design optimization, screw rotor has a unique profile, variable pitch design, with high vacuum, low exhaust temperature, stable operation characteristics. Due to the unique design, only static seal, so there is no leakage and wear of dynamic seal. It has a unique solution to the current working conditions of liquid and dust. The structure is simple, and the working parts and transmission parts are completely separated in the design, and the working parts can be cleaned and replaced without disassembly of the whole machine, and there are no vulnerable parts, so the management cost is saved.

vertical dry screw vacuum pump advantages and features:

There is no oil and no water in the cavity, providing clean vacuum, easy maintenance and cleaning.

Seal: no dynamic seal, industrial labyrinth seal ring, no leakage and wear,

Lubrication: there is no support or lubrication at the suction end. Forced lubrication with thin oil at exhaust end.

Vacuum degree: 1-2pa, 7.5 * 10-3mmhg

Exhaust temperature: < = 60 ℃ (under limit test)

Vibration, low noise: C-type flange connection, quiet operation, can be equipped with sound insulation cover, noise decibel < 70dB (a)

Unique solution: the unique design concept of vertical screw vacuum pump, top-down suction and exhaust mode, the use of free sedimentation and high-speed air flow, the liquid and dust can be smoothly discharged from the pump cavity, without dust and liquid entrapment accumulation problems. At the same time, it can be configured with automatic on-line cleaning, temperature and other automatic monitoring, which can avoid the horizontal screw dry pump in liquid and dust conditions The disadvantages of normal operation of the method.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)