vertical screw dry vacuum pump structural principle

Vertical screw dry vacuum pump is a kind of equipment that can be vacuumized. The reason why it can replace other similar products and become common equipment in industrial production is due to its better product performance and advantages, and it shows high stability in various environmental processes. So let’s learn about the vertical screw dry vacuum pump?

Dry vacuum pump belongs to environmental protection type vacuum pump, no sewage, recyclable solvent. Dry vacuum pump can be used in chemical, pharmaceutical, petrochemical, scientific research and other industries. It can be used normally in corrosive, corrosive, condensable and dust environment.

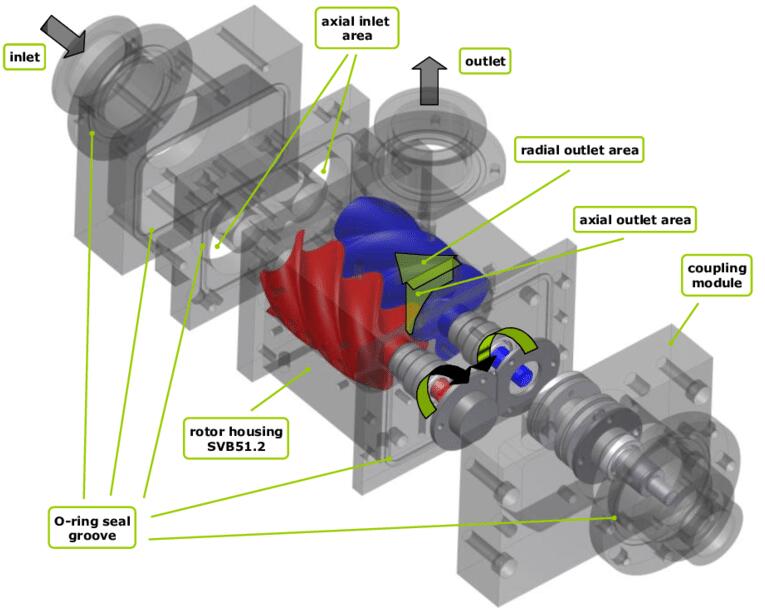

The vertical screw dry vacuum pump is mainly composed of three parts: driving part, transmission part and working part. The driving part is driven by high-performance three-phase asynchronous motor.

Transmission part: a number of high-precision synchronous gears in the transmission part, including the motor drive gear, the intermediate wheel and a pair of synchronous time limit gears connected with the rotor shaft, transmit the power generated by the motor to the working part; all the transmission gears are lubricated with oil, and at the same time, a forced lubricating oil pump is set at the bottom of the transmission box for forced lubrication of each bearing, greatly extending the maintenance period of the bearing.

Working part: a closed pump cavity is composed of the intake and exhaust pump cover and the pump shell. Inside the pump chamber, a pair of parallel male and female rotors are meshed with each other, and are suspended vertically in the closed pump cavity through the upper and lower end bearings. There are small gaps between the tooth surfaces of the male and female rotors and between the rotors and the pump cavity. The rotors rotate in the pump cavity without any friction and lubrication. Both ends of rotor shaft adopt special customized combined seal, which can ensure no leakage in various harsh processes. A complete water cooling jacket cooling system is formed in the closed pump cavity to cool the pump cavity, exhaust end, bearing and seal, and take away the heat of gas compression and bearing seal friction in time, so as to ensure the smooth rise of inlet and exhaust temperature, improve the production safety, and greatly extend the service life of bearings and seals.

Compared with the starting motor, the vertical screw dry vacuum pump has low vacuum degree and small air supply, but its volume is exquisite, easy to install, easy to maintain, convenient to move, and not to pollute the environment. It is also good to use it in places with high requirements. Therefore, in the purchase of screw vacuum pump to determine the required vacuum degree, if the demand is high, the selected screw vacuum pump will be higher than the required vacuum degree, otherwise it will not meet the working standard.

Vertical screw dry vacuum pump itself will not occupy a lot of space, and its installation is more convenient, users can easily operate it, especially it will not pollute the environment.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)