Water Ejector Pump System

What is water ejector pump system

The water ejector pump system is a stable and reliable evacuation device. The water jet vacuum pump is suitable for various process occasions such as distillation, concentration, drying, absorption, mass transfer, and sewage biochemical treatment.

Water Ejector Pump System Features and application :

Simple structure, small maintenance amount (low maintenance cost), long service life, reliable technology, stable vacuum degree (not with long service time, more maintenance times, but reduce vacuum degree) easy to use (without foundation and foundation, on the ground flat); it can directly suck some corrosive gas, flammable and explosive gas, various liquids and granular media; it can be used as vacuum crystallization , concentration, drying, evaporation, distillation, dehydration, filtration, vacuum conveying materials, chemical absorption, degassing, oxygen supply, large water pump for water diversion, can also be used for environmental protection to absorb tail gas and dust, change environmental pollution and working conditions. It is used in chemical industry, pharmaceutical industry, grease industry, light industry, rubber industry, textile industry, brick industry, sugar industry, salt industry, paper industry, food industry, ceramics industry, metallurgy industry, petroleum industry, environmental protection industry, mine concentration plant, etc.

SP type water jet vacuum pump performance parameters:

| SP——04 Type | SP——06 Type | SP——1 Type | SP——2 Type | SP——3 Type | |||||||

| kpa | mmhg | kg/h | m3/h | kg/h | m3/h | kg/h | m3/h | kg/h | m3/h | kg/h | m3/h |

| 4 | 30 | 2.4 | 51 | 3 | 76 | 6 | 126 | ||||

| 5.3 | 40 | 3.6 | 57 | 3.8 | 60 | 7.2 | 114 | ||||

| 6.6 | 50 | 4.5 | 56 | 5 | 64 | 8.4 | 106 | ||||

| 8 | 60 | 2 | 20 | 2.5 | 27 | 7 | 74 | 7.5 | 79 | 11.3 | 119 |

| 14.6 | 110 | 2.9 | 17 | 3.6 | 21 | 7.8 | 45 | 8.7 | 50 | 16.8 | 97 |

| 21.3 | 160 | 4.6 | 18 | 5.8 | 23 | 13 | 53 | 17 | 67 | 26.5 | 105 |

| 28 | 210 | 6.3 | 19 | 7.7 | 24 | 17 | 51 | 22 | 65 | 34 | 102 |

| 34.6 | 260 | 8 | 20 | 10 | 25 | 22 | 53 | 27 | 66 | 43 | 105 |

| 41.3 | 310 | 10.5 | 22 | 13 | 26 | 29 | 59 | 34 | 69 | 50.5 | 103 |

| 48 | 360 | 12 | 21 | 15 | 27 | 34 | 59 | 39 | 68 | 65 | 114 |

| 54.6 | 410 | 14.5 | 23 | 18 | 28 | 38.5 | 60 | 46 | 70 | 84 | 126 |

| 61.3 | 460 | 16 | 22 | 19 | 27 | 46 | 63 | 54 | 75 | 114 | 157 |

| 68 | 510 | 19 | 24 | 22 | 27 | 55 | 69 | 65 | 80 | 139 | 173 |

| 74.6 | 560 | 23 | 26 | 25 | 29 | 67 | 76 | 77 | 87 | 168 | 190 |

| 81.3 | 610 | 28 | 29 | 33 | 34 | 79 | 82 | 91 | 95 | 198 | 206 |

| 88 | 660 | 36 | 35 | 42 | 40 | 103 | 99 | 115 | 110 | 253 | 242 |

| 94.6 | 710 | 48 | 43 | 72 | 65 | 115 | 103 | 180 | 161 | 336 | 300 |

| 100 | 760 | 58 | 48 | 84 | 70 | 132 | 110 | 240 | 200 | 396 | 330 |

| Electromotor kw | 3 | 4 | 5.5 | 7.5 | 11 | ||||||

| Working water temperature 0C | 25 | 25 | 25 | 25 | 25 | ||||||

| SP——4 Type | SP——5 Type | SP——6 Type | SP——7 Type | SP——8 Type | |||||||

| kpa | mmhg | kg/h | m3/h | kg/h | m3/h | kg/h | m3/h | kg/h | m3/h | kg/h | m3/h |

| 4 | 30 | 7.2 | 152 | 8 | 117 | 10 | 203 | 11 | 253 | 13 | 304 |

| 5.3 | 40 | 8.4 | 133 | 10 | 152 | 12 | 190 | 14 | 247 | 16 | 285 |

| 6.6 | 50 | 9.6 | 122 | 13 | 183 | 16 | 213 | 18 | 243 | 20 | 274 |

| 8 | 60 | 15 | 152 | 19 | 203 | 22 | 228 | 24 | 253 | 27 | 279 |

| 14.6 | 110 | 24 | 138 | 31 | 180 | 36 | 208 | 43 | 249 | 48 | 277 |

| 21.3 | 160 | 36 | 143 | 41 | 162 | 53 | 209 | 60 | 238 | 67 | 266 |

| 28 | 210 | 46 | 138 | 53 | 160 | 66 | 200 | 75 | 225 | 94 | 283 |

| 34.6 | 260 | 54 | 132 | 63 | 152 | 84 | 205 | 96 | 234 | 118 | 287 |

| 41.3 | 310 | 65 | 133 | 82 | 167 | 102 | 209 | 132 | 270 | 149 | 304 |

| 48 | 360 | 84 | 148 | 96 | 169 | 132 | 232 | 178 | 312 | 184 | 339 |

| 54.6 | 410 | 110 | 170 | 132 | 204 | 162 | 250 | 203 | 314 | 216 | 334 |

| 61.3 | 460 | 114 | 198 | 156 | 215 | 198 | 273 | 252 | 347 | 276 | 380 |

| 68 | 510 | 163 | 203 | 204 | 253 | 240 | 298 | 324 | 402 | 348 | 432 |

| 74.6 | 560 | 190 | 215 | 240 | 272 | 312 | 353 | 360 | 407 | 408 | 462 |

| 81.3 | 610 | 240 | 250 | 300 | 312 | 384 | 398 | 432 | 449 | 504 | 523 |

| 88 | 660 | 324 | 310 | 456 | 438 | 504 | 484 | 540 | 519 | 600 | 576 |

| 94.6 | 710 | 372 | 332 | 564 | 503 | 648 | 578 | 732 | 653 | 810 | 728 |

| 100 | 760 | 480 | 400 | 624 | 520 | 720 | 600 | 840 | 700 | 960 | 800 |

| Electromotor kw | 15 | 18.5 | 22 | 30 | 37 | ||||||

| Working water temperature 0C | 25 | 25 | 25 | 25 | 25 | ||||||

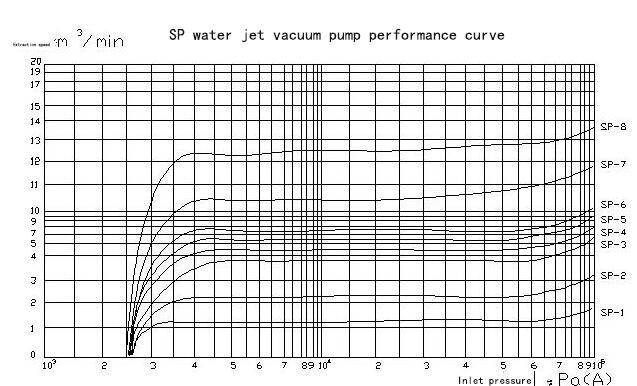

SP type water jet vacuum pump performance curve: