water ring compressors for quality acceptance standards

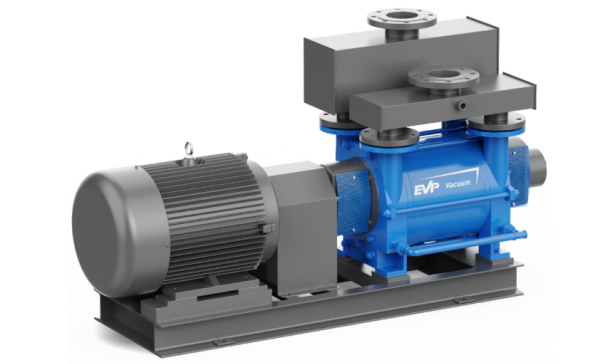

The water ring compressor, as a type of positive displacement compressor, forms a closed space inside the compression chamber by rotating the water ring, achieving the purpose of compressing gas. Due to its excellent sealing performance and noise reduction effect, it is widely used in various fields such as pharmaceuticals, chemicals, food processing, and papermaking. It is crucial to establish and implement strict quality acceptance standards to ensure the quality and performance of compressors.

1. Appearance inspection is the primary step. Check whether the compressor casing is intact and undamaged, and the surface should be free of rust, corrosion, and obvious scratches. At the same time, the installation of wires should be neat and well grounded to ensure electrical safety. In addition, product identification and nameplates should be clearly visible for easy maintenance and operation in the future.

2. Performance acceptance is a crucial step. Professional testing instruments are required to measure the flow rate and pressure of the water ring compressor to ensure its rated flow rate and pressure stability. During overload operation, the temperature rise should be controlled within a reasonable range to avoid overheating and damage. Noise testing cannot be ignored to ensure that the noise of the compressor does not exceed the specified standards, in order to reduce the impact on operators and the environment.

3. The acceptance of work environment also needs to be taken seriously. Check whether the installation position of the compressor meets the requirements, whether the ventilation is good, and ensure that the compressor can operate in a better state. At the same time, confirm that there are no flammable or explosive materials around to ensure production safety. In addition, it is necessary to check whether safety measures such as power supply and grounding are properly set up to prevent electrical accidents.

In summary, the quality acceptance criteria for water ring compressors cover multiple aspects such as appearance, performance, and working environment. Only by strictly implementing these standards can we ensure the purchase of qualified and reliable compressors, providing stable gas compression support for the production process. Meanwhile, regular maintenance and upkeep are also important means to extend the service life and improve production efficiency.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)