water ring pump coupling installation and adjustment

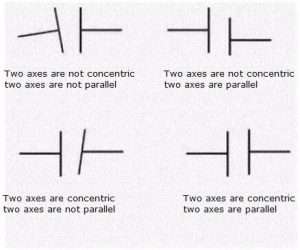

Coupling alignment is also called finding a concentricity. After the pump and the motor are all installed, the last task is to find the pump and the motor to be concentric, that is, to align the pump and the axis of the prime mover on the same straight line so that it will not vibrate during operation. When the newly installed pump is aligned, radial and axial errors of the coupling may occur in the following four situations:

First Method:

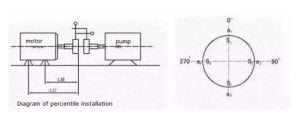

General pumps (pumps, small pumps) can be used for rough measurements with flat or feeler gauges, but most devices require precision measurements with a dial indicator. The level of the general pump has been found to be good, with the pump on the basis of the wheel, measuring and adjusting the motor on the wheel, to ensure the two-axis alignment of the motor and the pump.

Note: a1, a2, a3, a4 are radial clearances, S1, S2, S3, S4 are for axial clearance measurements. The radial clearance a1 and axial clearance S1 of the dial indicator at 0° are measured first, and then measured separately. The radial and axial clearances of 90°, 180°, and 270° are recorded and recorded in the circles and circles shown above. When the measurement returns to 0°, it must be consistent with the original reading. Otherwise, the cause must be searched, which is usually caused by loose shaft or loose anchor bolts. The last measurement data must also meet the following conditions to indicate that the calculation is correct.

Second Method:

Put the dial indicator to the pump end, dial the dial indicator to zero, rotate the wheel one revolution, get a value every 90 degrees, and finally the dial indicator must return to zero when it returns to its original position. The addition of the left and right readings should be equal to The sum of the upper and lower numerical values. Then according to the readings, the relative spatial positions of the two axes are analyzed, and appropriate adjustments are made according to the deviation values. First adjust the left-right deviation of the coupling to the allowable value, and then adjust the height to within the standard.

Find the formula:

S1 = ± (axial difference between the wheel (open mouth absolute value) × foot 1 to the measuring point distance) measuring point diameter ± circumferential radial interpolation (difference) value / 2;

S2 = ±(Axial difference of the pair of wheels × Distance from the foot 2 to the measuring point) Measured point diameter ± circumferential radial interpolation (difference) value/2.

The first ±: If you are on the top of the wheel, take the “+” sign; if it is the bottom of the mouth, take the “-” sign can be understood as going from the top to the bottom;

The second ±: Take “+” when the motor is low, and “-” when the motor is high. It can be understood that the table is positive or negative.

If S1 is positive (the upper mouth is open and the motor is low), it means that the shim should be cushioned, and the S1 number is the thickness of the shim to be cushioned.

Another: The measuring point diameter is the measuring point rotation diameter, not the coupling diameter. The adjustment is similar to that of the left and right.

Third Method:

Addition and subtraction cushion calculation method

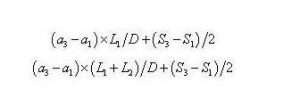

From this formula:

A indicates the axial reading

D indicates the diameter of the backrest wheel

L1 represents the distance from the backrest wheel to the front leg of the motor

L2 represents the distance from the front to the rear of the motor

S indicates radial table reading

The result of this is the number of mats your motor will add to the forefoot and back.

Tags : water ring pump

Edited by Jinny Zhang / EVP vacuum solution

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)