water ring pump in brick industry

As a kind of rectangular building material used for building walls, bricks are closely related to everyone’s life. The size of Chinese standard clay bricks is 240×115×53mm.

In the 1960s, China’s vacuum brick machines imported from abroad were equipped with water ring type vacuum pumps. Due to the limitation of China’s vacuum technology level at that time and the low level of brick machine manufacturing, domestic water ring pumps The application on the brick machine is very unsatisfactory, mainly manifested as: low ultimate vacuum, low pumping rate (under the same power state), unstable performance and many other shortcomings. However, due to the high price of imported equipment from abroad, it is not suitable for domestic production. In the environment, many manufacturers have to choose old-fashioned reciprocating vacuum pumps. Due to the structure and working principle of the reciprocating vacuum pump, the vacuum pump consumes a lot of fuel and is noisy, and each transmission part is purely mechanical friction. The replacement of wearing parts is very frequent, and it is often necessary to stop due to a small problem. , It affects the production efficiency of production enterprises and increases the operating cost of equipment.

After the first Wall and Roofing Material Production Equipment exhibition held in Chongqing in 1998, the water ring vacuum pump was gradually recognized and used by many manufacturers, and gradually replaced the reciprocating vacuum pump, becoming the mainstream configuration of the vacuum system of the vacuum brick machine.

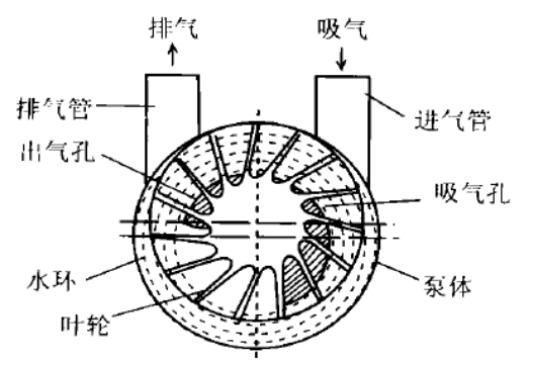

The water ring vacuum pump is a vacuum pump that obtains a rough vacuum. Its ultimate pressure is -0.098MPa for a two-stage pump, and can reach -0.099MPa if an atmospheric ejector is connected in series. The working principle of the water ring vacuum pump is shown in the following figure. The water ring pump is composed of several parts such as the suction hole and exhaust hole of the water ring of the impeller pump body. The impeller is eccentrically installed in the pump body. When the impeller rotates, the water is thrown out by centrifugal force, forming a rotating water ring between the inner wall of the pump and the impeller. The upper inner surface of the water ring is in contact with the impeller hub. When rotating in a clockwise direction, during the first half of the revolution, the inner surface of the water ring gradually separates from the hub, and the cavity formed between two adjacent blades gradually increases. The pumped air passes through the pump intake pipe and sucks in the crescent shape. The hole is continuously sucked into the cavity; during the second half of the revolution, the inner surface of the water ring gradually approaches the hub, and the cavity between two adjacent blades gradually shrinks, and the gas is compressed, so the pressure continues to increase. When the pressure increases to greater than When the external pressure is applied, the gas is discharged, and the gas is continuously pumped away to form a certain vacuum. In the working process, the heat generated by the work will cause the water ring to heat up, and part of the water and gas will be discharged together. Therefore, during the work, the water consumed in the pump must be supplemented to meet the working requirements of the pump. The two-stage water ring vacuum pump is composed of a high vacuum stage and a low vacuum stage, and each stage is composed of an impeller-pump body suction and exhaust disc. The working principle of each level is consistent with the above.

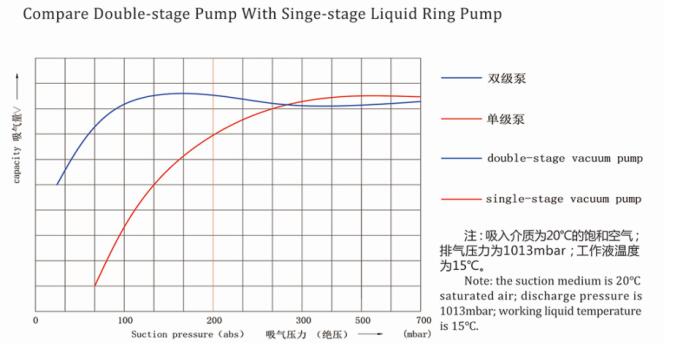

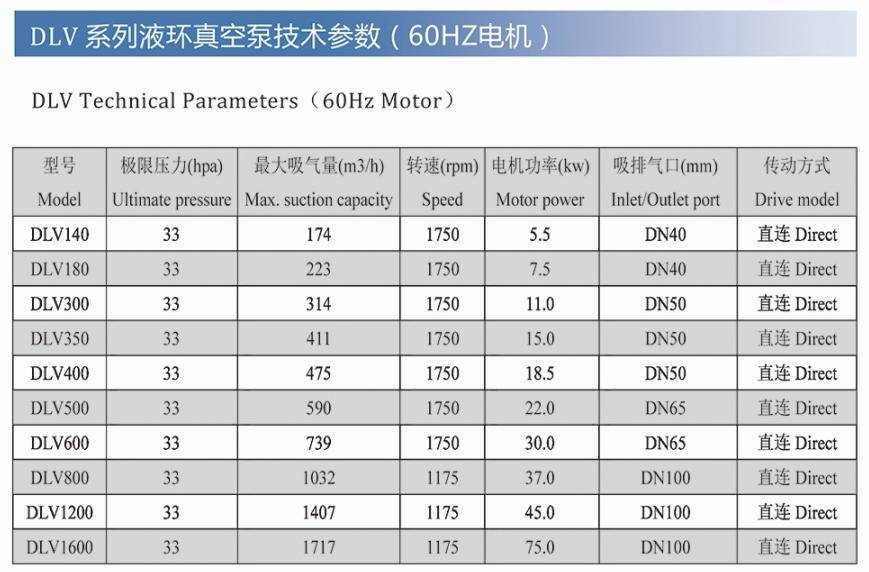

The two-stage water ring vacuum pump commonly used in the brick industry is the DLV series. The DLV series two-stage water ring vacuum pump is a new type of two-stage water ring vacuum pump developed by our company on the basis of the 2SK series and combined with the German two-stage pump design index. DLV series water ring vacuum pumps are designed with a two-stage compression process. The pumping speed is stable in a higher vacuum range, or it can maintain a higher vacuum in a large pumping rate range. When working in a higher vacuum, the efficiency is 35% to 40% higher than that of a single-stage water ring pump, and energy consumption is correspondingly reduced.

It can be seen from the curve above that the single-stage water ring vacuum pump is suitable for use in working conditions where the vacuum degree is not required, and its suction capacity is relatively large. But when working in a higher vacuum range, the suction volume is severely attenuated (below 200mbar starts to attenuate sharply, and when it is less than 100mbar, the attenuation is severe). Under this working condition, the vacuum pump has extremely low efficiency and high power consumption. The two-stage water ring vacuum pump can obtain a larger suction volume in a higher vacuum range, and the efficiency is 30% to 40% higher than that of the single-stage water ring pump in the high vacuum working state, and the energy consumption is correspondingly reduced. The two-stage water ring pump is more suitable for working conditions that require a larger pumping volume while maintaining a higher vacuum.

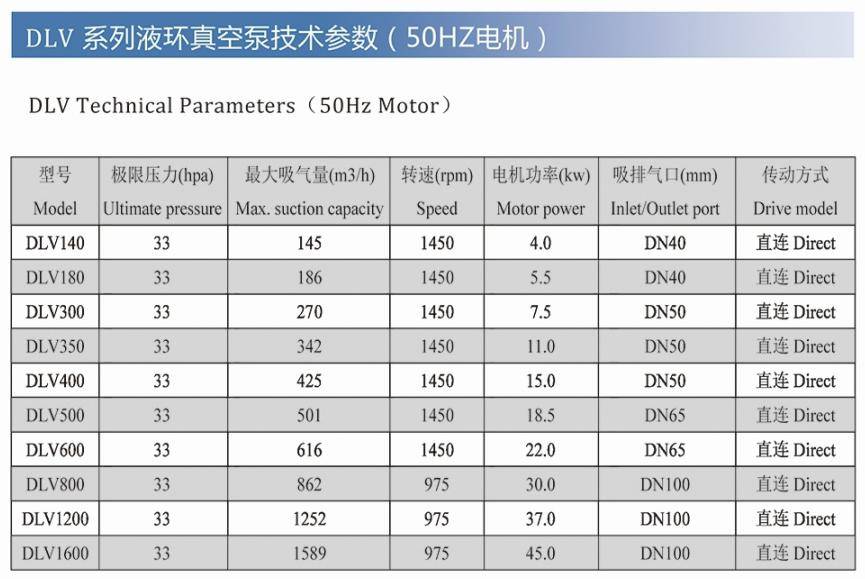

The following is the basic parameter table of DLV. Customers can choose the appropriate vacuum pump according to the required parameters. If you have any questions, you can contact us.

Edited by: Emily Fu; Copyright: EVP Vacuum Solutions

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)