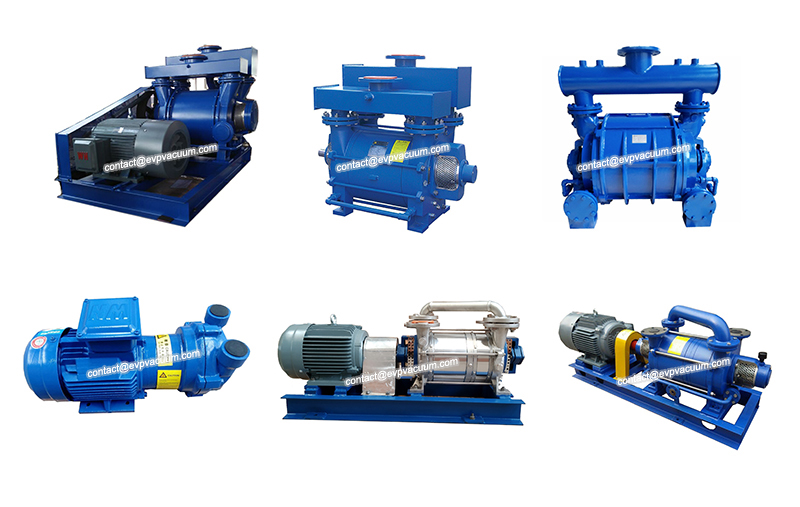

water ring pump type

As a kind of crude vacuum pump, water ring pump has a great disadvantage in environmental protection, but it is still widely used in many fields because of its easy processing, isothermal compression, flammable and explosive gas pumping and other characteristics. Before this, we introduced some basic information about the water ring pump. The introduction about the type of water ring pump is only a simple one. This time, we will make up for it here.

There are four types of water ring pump in practical application

1. Single stage single acting water ring pump

The water ring pump has only one impeller, that is, the so-called single-stage, single action refers to that every rotation of the impeller, suction and exhaust are carried out once respectively. It is the simplest type of water ring pump, with low ultimate pressure, low pumping speed and efficiency.

2. Single stage double acting water ring pump

On the basis of single-stage single acting water ring pump, the suction and exhaust actions of the impeller will be carried out twice for each rotation cycle, which is referred to as double acting. Under the same pumping speed, the double acting double ring vacuum pump has smaller size and weight than the single acting one. At the same time, because the working cavity is symmetrically distributed on both sides of the hub, the load on the rotor is effectively improved. In practical application, the double acting water ring pump has high pumping speed, high efficiency and relatively high limit pressure. However, due to the complexity of single action in structure, it is very difficult to process.

3. Double stage water ring pump

The two-stage water ring pump can be simply understood as two single-acting pumps in series, which connect the impellers of two single-stage single acting water ring pumps with one mandrel. The main feature of this type of water ring pump is that it still has a large pumping speed under low pressure.

4. Gas ejector + water ring pump unit

Water ring pump unit is generally composed of air ejector and water ring pump, which is mainly to improve the pumping speed of the equipment under low pressure, avoid cavitation phenomenon of water ring vacuum pump, and expand the scope of use of water ring pump. In practical application, the ejector is connected with the air inlet of the water ring pump. Firstly, the water ring vacuum pump is started to make the pre vacuum and differential pressure required for the operation of the air ejector, which drives the gas; after momentum exchange and compression between the ejector and the extracted gas, the gas enters the water ring pump, and then is discharged after compression.

These four kinds are the common types of water ring pump. Of course, in practice, the water ring pump is often used as the front pump in various vacuum units.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)