Water ring pumps are used in the oil and gas industry

Liquid ring vacuum pump mechanical seal API682

In oil & gas industry, it’s usually required to equip double end sealed mechanical seal for liquid ring vacuum pump, complying with API682 standard. While external flushing system (named as cooling system) comes to be necessary.

here we would like to introduce the major flushing system for double end sealed mechanical seal as below:

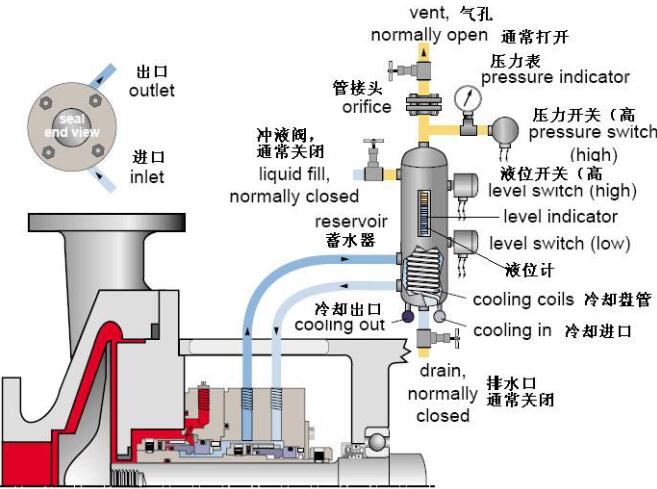

Plan 52 (serial sealing with non-pressure flushing tank)

Description: external flushing tank provides buffer solution for outboard mechanical seal. In normal operation, the internal fluid supply ring keeps circulation, the flushing tank keeps discharging steam to steam recycle system and keep small pressure in sealing chamber.

Advantage: external mechanical seal belongs to main seal, without or minimal waste discharge in working process, no pollution in working process.

Suitable application: seal with double end pressurized, high vapor pressure fluid, light hydrocarbon, danger/toxic fluid, diathermanous fluid.

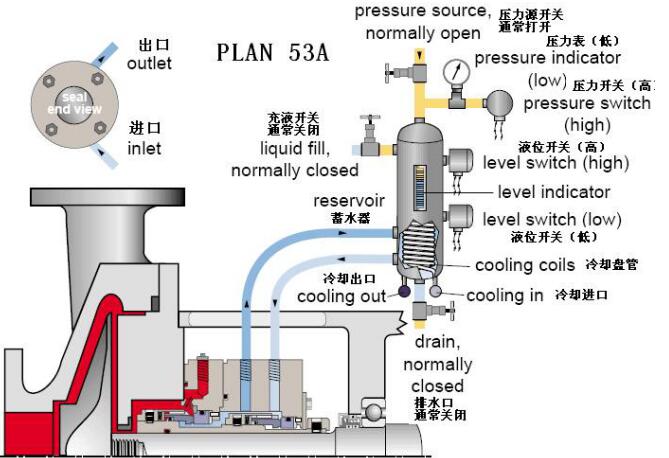

PLAN53A : double end sealed mechanical seal with pressurized sealing fluid.

Description: external pressurized isolation fluid tank provides clean fluid to sealing chamber. Circulation completed by internal liquid supply ring. Pressure in isolation fluid tank is higher than that of sealed working process fluid.

Advantage: isolate working fluid, zero working fluid discharge

Suitable application: seal with double end pressurized, high vapor pressure fluid, light hydrocarbon, danger/toxic fluid, diathermanous fluid, dirt , corrosive or polymerizable fluid.

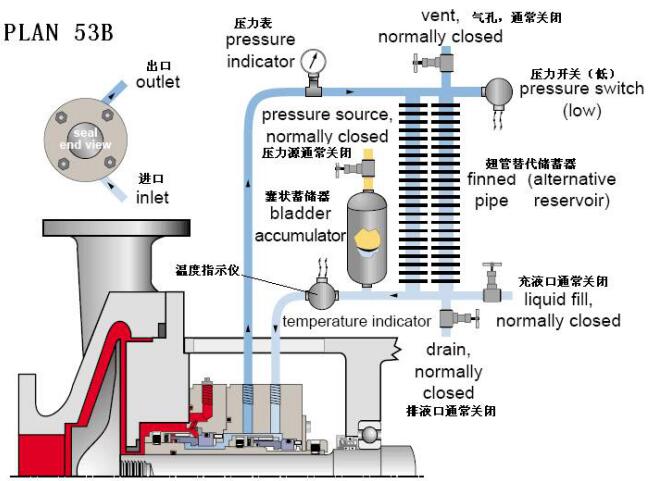

PLAN 53B (double end seal with compulsive circulation for sealing fluid)

Description: to provide fluid for outward sealing of pressurized double end sealing device through external piping system. The advanced pressurized pressure tank can provide pressure to circulation system. Its flow rate is kept through internal circulation liquid. The heat from circulation system is removed by air or water cooled heat exchanger.

Advantage: able to separate fluid of working process, zero flow path emission, higher pressure than Plan 53A

Suitable application: seal with double end pressurized, high vapor pressure fluid, light hydrocarbon, danger/toxic fluid, diathermanous fluid, dirt , corrosive or polymerizable fluid.

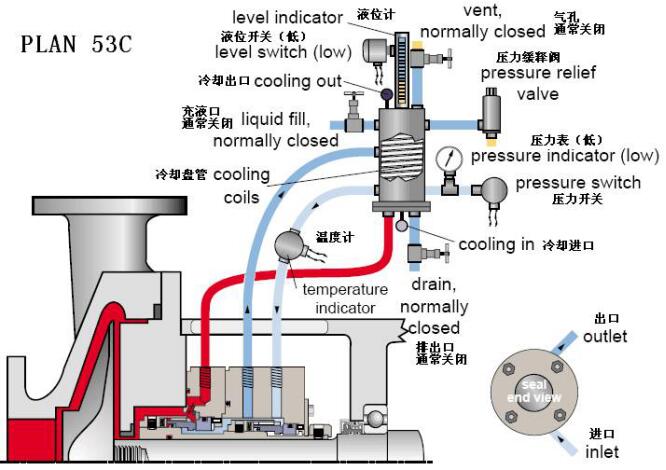

PLAN53C : double end sealed mechanical seal with pressurizing tank.

Description: external pipeline system provides isolation fluid for outboard seal of mechanical seal. Pressure of circulation system is provided by pipeline from sealing chamber to plunger accumulator. Flow is ensured by internal fluid supply ring. The heat from circulation system is cooled by air or water cooled heat exchanger.

Advantage: isolate working fluid, zero working fluid discharge, higher pressure than PLAM53A, dynamic track on system pressure.

Suitable application: seal with double end pressurized, high vapor pressure fluid.

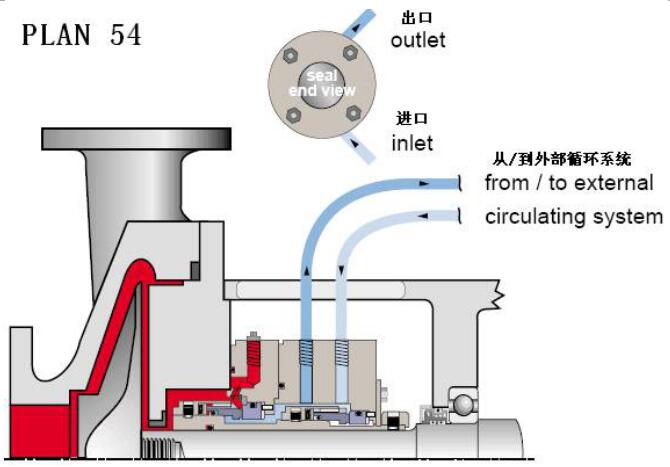

PLAN54 (double end seal with external led sealing fluid)

Description: set with external pressurizing separation fluid tank or system to provide clean fluid for sealing chamber. Its sealing fluid circulation is completed by external pump or pressure system. The pressure on fluid tank should be higher than pressure of working fluid.

Advantage: able to separate fluid of working process, zero flow path emission, sealing is unable to promote circulation.

Suitable application: seal with double end pressurized, high vapor pressure fluid, light hydrocarbon, danger/toxic fluid, diathermanous fluid, dirt , corrosive or polymerizable fluid.

EVP has sufficient experience for such system, followed case uses our 2BE1-203 pump model, with EagleBurgmann mechanical seal in PLAN 52 flushing system for one of government owned oil & gas company.

Tags: liquid ring vacuum pump,Liquid ring vacuum pump system

Edited by Shell Hu