water ring vacuum pump corrosion resistant material

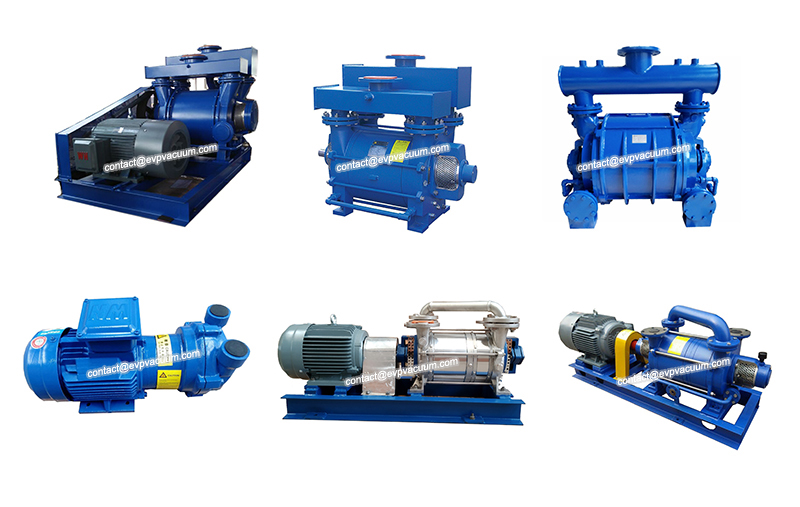

Water ring vacuum pump is often used in the industrial field, which is mainly used for vacuum extraction. It is undeniable that the working environment in the industrial field is mostly complex and harsh, especially there are many substances with corrosive substances, such as corrosive gases. At this time, the materials of the vacuum pump body required must be very good in corrosion resistance, otherwise, the vacuum pump will also be used after the completion of the work Will be damaged. Next, we will introduce the corrosion-resistant materials of the pump body of the water ring vacuum pump.

1. water ring vacuum pump gray cast iron material:

Grey cast iron is a kind of cast iron which is obtained by fully graphitization in the first stage. All or most of the carbon exists in the form of flake graphite, and the fracture is gray dark. Therefore, it is named as grey cast iron, inoculated cast iron, rare earth grey cast iron, etc. Gray cast iron has certain strength, but its plasticity and toughness are very low. This property is related to the properties of graphite itself and its existing form in cast iron structure. It has good shock absorption property. When making parts such as base or frame of machine equipment with gray cast iron, it can effectively absorb the vibration energy of machine; it has good lubrication performance; it has good thermal conductivity, because graphite is a good conductor of heat; in addition, its smelting is relatively convenient, and it has good casting performance. It is suitable for castings with complex structure and thin-walled castings because of its good fluidity, small linear shrinkage and volume shrinkage, and its castings are not easy to crack. It is mainly used in the complex parts of water ring vacuum pump, which has the characteristics of high strength and long service life, good corrosion resistance and low price.

2. water ring vacuum pump ductile iron material :

Spheroidal graphite is obtained by spheroidization and treatment, which effectively improves the mechanical properties of cast iron, especially the plasticity and toughness, so as to obtain higher strength than carbon steel. Nodular cast iron is a kind of high-strength cast iron material developed in the 1950s. Its comprehensive properties are close to that of steel. It is based on its excellent properties that nodular cast iron has been successfully used to cast some parts with complex stress, high strength, toughness and wear resistance requirements. Nodular cast iron has developed rapidly into a widely used cast iron material next to grey cast iron. The so-called “iron for steel” mainly refers to ductile iron.

3. water ring vacuum pump impeller stainless steel material :

Impeller stainless steel material has 304 stainless steel, 316 stainless steel, 316L stainless steel;

4. water ring vacuum pump material flow parts stainless steel:

2BV series water ring vacuum pump, pump body, disc and impeller are made of 304 stainless steel, 316 stainless steel and 316L stainless steel; impeller is made of stainless steel, which can be used in some specific environments or environments with low requirements and low corrosivity.

5. water ring vacuum pump integral stainless steel material :

2BV series water ring vacuum pump, pump body, disc, impeller, pump cover and pump shaft are made of 304 stainless steel, 316 stainless steel and 316L stainless steel; (2be series, 2SK series, SK series and Cl Series) pump body, disc, impeller, pump cover, pump shaft, connecting pipe, upper steam separator (2be series water ring vacuum pump is made of), etc. It is mainly used for gases with high humidity, relatively resistant to oxidation and relatively high price.

When the user selects the corrosion-resistant pump body material of water ring vacuum pump, he should first know what type of material his vacuum pump is suitable for, and combine with the relevant use conditions. He should not choose to buy this type of corrosion-resistant material if he thinks it is better, which is the key from the reality. The vacuum pump produced by the manufacturer with good reputation is guaranteed in all aspects, including its corrosion resistance, which is better than that of the general vacuum pump.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)