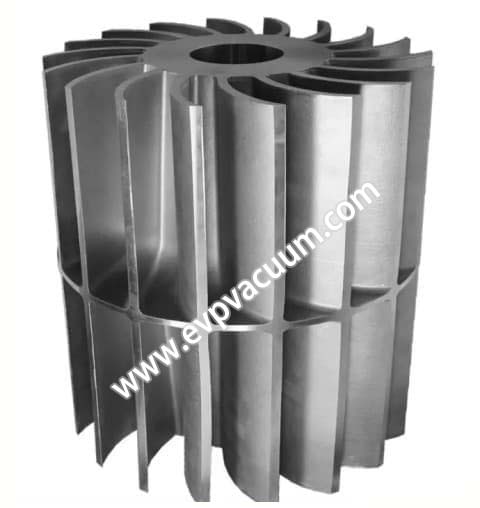

water ring vacuum pump impeller repair method

Impeller is a very important part of water ring vacuum pump, which has a great impact on the work of water ring vacuum pump. Once the impeller has problems, it will certainly affect the working state and efficiency of water ring vacuum pump. So we found the fault, the first thing is to see the specific damage, timely repair or replacement. Then EVP water ring vacuum pump manufacturers to share some of the impeller repair methods, hoping to help you.

The repair methods for impeller of water ring vacuum pump are as follows:

1. In case of groove marks or slight eccentric wear, abrasive cloth can be used to polish the wheel hub, and the wheel can be polished if the thickness is allowed. Or use metal spraying method to restore the original size.

2. General impeller corrosion, such as not serious sand holes, can be repaired by repair welding. The copper impeller of water ring vacuum pump is repaired with brass, and the cast iron impeller is also welded with brass.

3. When the sealing edge of the double ring inner ring of the impeller of water ring vacuum pump is worn out with groove marks, or the phenomenon of eccentric wear is not serious, it can also be polished with abrasive cloth. If the thickness is allowed, it can also be turned smooth. If the wear or eccentric wear is serious, the new inner ring can be replaced.

4. The repair welding method of water ring vacuum pump impeller is to clean the parts to be welded before welding to remove oil, rust and oxide scale. It can be partially or wholly preheated to 250 ~ 450. Powder 30i is generally used as welding powder, wire 224 silicon brass as welding wire. Slight oxidation flame or neutral flame shall be used for welding wire and gas welding flame. Pressure welding method is generally used during operation to reduce overheating of weld metal and improve weld formation. During operation, direct contact between high temperature flame core and molten pool metal shall be avoided as far as possible to avoid porosity in weld metal. Heat preservation and slow cooling after welding to eliminate stress and improve performance. After cooling, machining can be carried out.

5. Static balance test should be carried out on the impeller of water ring vacuum pump or repaired impeller of water ring vacuum pump. Put the tested impeller on the milling machine, and mill the chips with the same weight as the object clamped by the lighter side during the balance test on the heavier side. However, the thickness milled on the impeller cover plate shall not exceed 1 / 3 of the thickness of the impeller cover plate, and it is allowed to cut on the front and rear cover plates, and the cutting part trace shall be smooth transition with the cover plate disc.

How to deal with the impeller, we should first know what causes the impeller damage, so as to solve the fundamental problem, and then repair the impeller, so as to avoid the possibility of impeller damage again. At the same time, after the impeller is repaired, the EVP water ring vacuum pump manufacturer suggests to do some related maintenance, which can effectively improve the repair quality.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)