Three-lobes Roots blower for cement plant

Roots blower is one of the key equipment in cement production line. The quality and operation of Roots blower directly affect the yield and quality of clinker. Roots blower has stable performance and good operation condition, which provides guarantee for normal production.

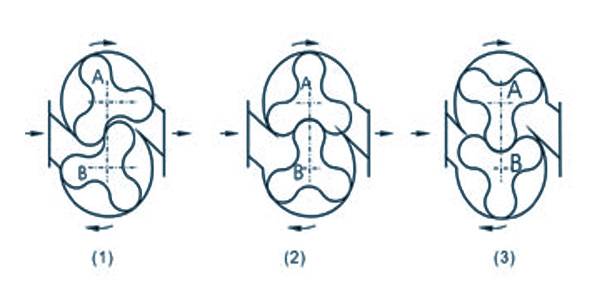

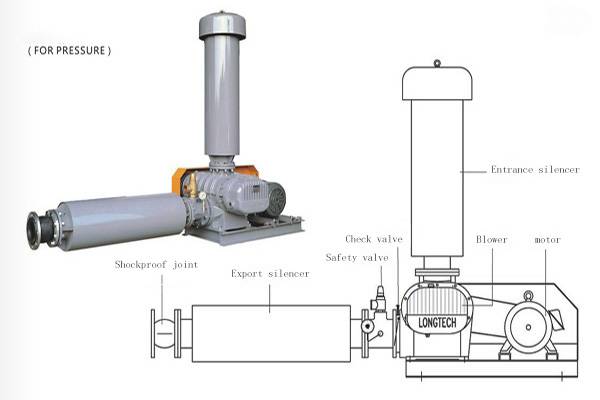

1.Principle of Roots Blower

Roots blower belongs to positive displacement type, the air volume is proportional to the number of revolutions, and the Roots blower is three lobes type(2 impeller, each impeller has three lobes), with strong versatility, convenient maintenance, long service life and good energy saving effect. The impeller of the three lobes type is sucked and discharged by two impellers three times each time. Compared with the two lobes type, the gas pulsation becomes less, the load change is small, the mechanical strength is high, the noise is low, and the vibration is small. Two three-lobes impellers are arranged on two parallel shafts. The inner hole surface of the wheel and the elliptical chassis and each impeller always maintain a small gap, because the impeller rotates uniformly in the opposite direction. The box and impeller are surrounded by a certain amount of gas from the suction side to the discharge side. Each impeller always keeps the correct phase by the synchronous gear and does not touch each other, so it can be high speed, no internal lubrication, simple structure, stable operation and stable performance.

2. Structure and Size of Roots blower:

3. Points for attention

Roots blower is simple in principle, stable in performance and easy to manage and maintain. However, the safe operation and service life of roots blower ultimately depend on the normal use and standard maintenance of the equipment. It is necessary to strengthen the inspection and inspection system of the equipment and deal with the abnormal or hidden trouble in time to ensure the safe, reliable and stable operation of the blower.

(1) Roots blower must start under the condition of no load, open all the inlet and exhaust valves of the blower before starting, and gradually adjust the valve after starting normally, so that the air volume reaches the required value, and the rated air volume is not allowed to be adjusted at one time.

(2) Roots blower should not stop suddenly at full load operation, and must gradually reduce the air volume before stopping to avoid damage to the blower.

(3)During the normal operation, each shift should be regularly inspected, with the focus on checking whether the bolts in each part are loose and whether there is oil leakage in the lubrication parts, and whether the temperature of both ends of the bearings and the fan shell is normal, etc., so as to make all inspection records

(4) Check the lubrication and cooling system of Roots blower regularly, pay attention to the quality of lubricating oil and listen carefully to whether there is any noise in the blower operation to judge the operation of rotor shaft and impeller.

(5) The overload or abnormal operation of Roots blower is gradually reflected, there is a quantitative process, pay attention to the inlet and exhaust pressure of the blower, the temperature rise of the bearing and the operating load current of the blower motor at any time. If the above parameters fluctuate, the blower should be diagnosed and checked in time to avoid further expansion of the fault.

(6) Regular annual overhaul of the Roots blower for timely inspection and adjustment of the clearance between impeller and impeller, impeller and shell, impeller and panel, if the clearance is beyond the allowable range, it shall be adjusted by experienced maintenance personnel.

(7) The inspection and repair of Roots blower shall be carried out by special personnel. All special tools shall be prepared before the shell and shaft are removed. The mechanical dimensions and clearance sizes shall be carefully measured and recorded during the disassembly process. It is best to mark the parts to ensure that the assembly dimensions meet the technical requirements of the factory and that the technical performance of Roots blower is maintained in an effective state.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)