water ring vacuum pump in plastic extrusion machine for degassing

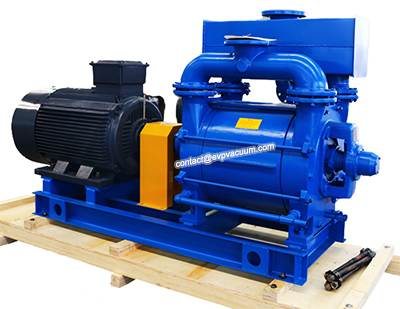

The water ring vacuum pump is applied to the plastic extrusion machine for degassing. The plastic extrusion degassing system provided is specially developed for degassing the plastic melt in the extruder. In this field, our company has many years of rich experience. Plastic extrusion degassing system is usually equipped with water ring vacuum pump, which is extremely energy-saving and suitable for variable frequency motor. Next, we will explain why we choose water ring vacuum pump instead of other types of vacuum pump.

The reason why we choose water ring vacuum pump to achieve continuous speed control of this kind of equipment is not only because we are the main supplier of this kind of vacuum technology, but also based on his good cooperation experience with us in the plastic industry for so many years, plus this water ring vacuum pump has many advantages.

Water ring vacuum pump has the following advantages:

1. The vacuum degree is as high as – 98kpa, leading in the industry.

2. It is equipped with rubber shock pad, which makes the operation more stable.

3. 100% oil-free and maintenance free.

4. Mute and control the noise at about 55dB.

5. Small size and beautiful appearance.

6. It is equipped with overload protector and will not burn out due to overload.

In the face of this special application demand, the two sets of plastic extrusion degassing systems provided completely meet the needs of customers. The system is mounted in a mobile frame and can be moved and connected to the degassing hood as required. The degasser controller is connected to the extruder through a simple plug-in and allows automatic operation of the entire system. The extruder controller sends “start / stop” and vacuum setting signals to the degassing system. The controller continuously sends the tested vacuum value back to the extruder controller and gives an alarm when the setting deviates from the test value or the equipment fails. The system also includes an integrated separation system for condensing gas and water vapor.

This modern technology has been applied to all material processes of twin-screw mixing extruder, including high temperature polyamide, with melting point temperature up to 350 ° C and PP, PC, PC / ABS, POM and PLA. Application in the production of micro particle products is a specialty of our company.

Only dry vacuum pumps can be used in this application. The traditional vacuum pump has the disadvantage that the working fluid is polluted: the extracted gas and water vapor will mix with the working fluid of the vacuum pump. In this environment, the oil lubricated vacuum pump also needs high maintenance cost, and its working oil and filter element must be replaced frequently. Therefore, water ring vacuum pump is the most suitable choice in this field.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)