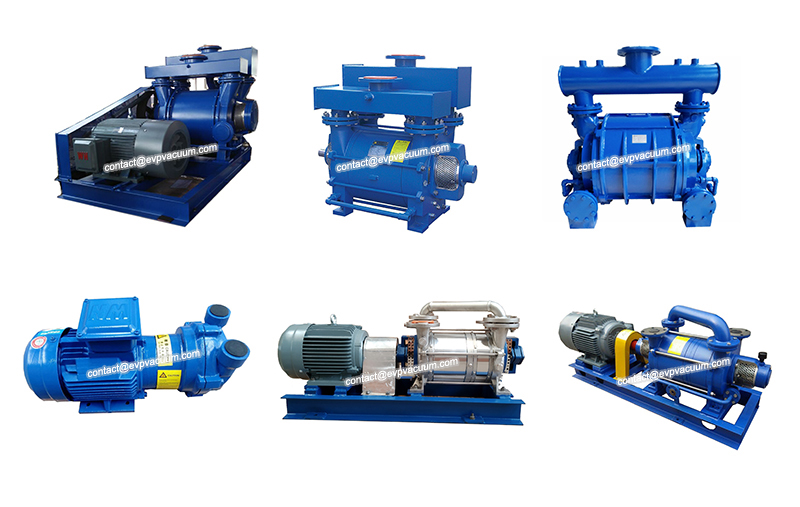

water ring vacuum pump in transportation and storage

Water ring vacuum pump is widely used in chemical industry, oil production and processing, steam turbine condenser vacuumizing, plastic industry, paper industry, food industry and many other industries. It is especially suitable for transportation and storage process industry.

The crude oil extracted from oil reservoir is always accompanied by low molecular weight hydrocarbon gases such as methane, ethane, propane and hydrogen sulfide gases. These gases must be removed before storage, transportation and distillation to stabilize the crude oil. At the same time, the components of aviation gasoline, especially their isomers (hydrocarbons with high seismic performance in the tender material), which are taken away by the volatilization of low molecular hydrocarbon gas, are recovered and utilized. In order to reduce the excessive loss of crude oil in the process of storage and transportation, stabilize the composition of crude oil and gasoline products, and not easily change the composition of fractions in storage, a large vacuum crude oil stabilization device has been set up in some foreign oil fields to degasify crude oil in a vacuum of 310-350mmhg to stabilize crude oil.

Vacuum refrigeration in order to store the propane and butane separated from the crude oil in the atmospheric sickle conveniently, the method of deep freezing was used to liquefy them in the past, but at present, many foreign manufacturers use vacuum refrigeration to evaporate the frozen part of propane under vacuum, so that the low temperature below – 48 ℃ can be easily obtained, and then the propane and butane are respectively at – 48 ℃ and – 10 ℃ Liquefied at low temperature, stored or transported in tanks.

After the air discharged from the oil tank is not loaded into the storage tank through stable crude oil, a lot of losses will be caused when the oil tank “breathes” due to the volatilization of light components. If the tank is evacuated by vacuum device, the liquefied petroleum gas (propane and butane) and liquefied natural gas (methane and ethane) can be removed, recycled and utilized.

Therefore, in the transportation, it can only be used to lift the lifting equipment to the lifting ring for handling, and the more detailed contents are as follows:

1. Before transporting the pump, it is necessary to drain the oil in the bearing box, screw off the drain plug with sealing gasket to drain the oil, and wipe off the oil drops on the box.

2. The oil in the shaft seal box (oil cup) does not need to be discharged.

3. The vacuum pump shall be transported and stored in a horizontal position. Otherwise, even before the pump is filled with oil, there is a risk of bearing box oil entering the pump cavity.

4. The pump can only be moved and installed horizontally. Otherwise, the oil in the shaft seal box will flow out.

5. The motor shall be protected from dust and water.

We can learn from the above that the water ring vacuum pump is very suitable for the transportation and storage industry.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)