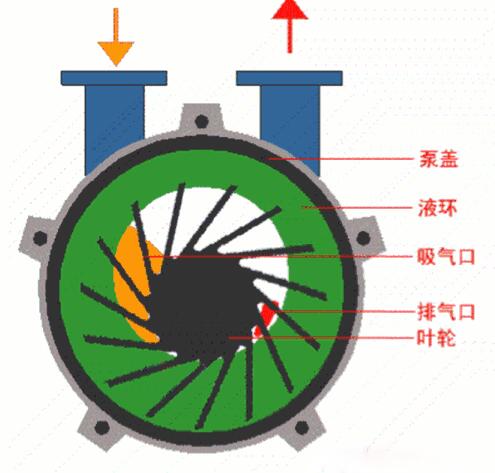

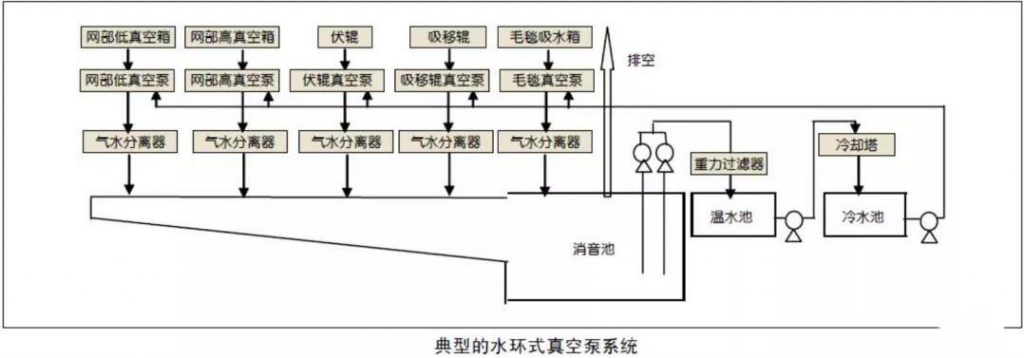

Water ring vacuum pumps

Water ring vacuum pump is one of the most commonly used vacuum pumps in paper industry. Most of the paper machine projects completed at present still use water ring vacuum pump as the standard of vacuum system.

water ring vacuum pump Advantages :

1. The structure is simple, the manufacturing accuracy is not high, and it is easy to process.

2. Compact structure, high speed pump, generally can be directly connected with the motor, without deceleration device. Therefore, with a small structure size, we can get a large amount of exhaust gas and occupy a small area.

3. Compressed gases are basically isothermal, i.e. the temperature change of the compressed gases is very small.

4. Because there is no metal friction surface in the pump chamber, there is no need to lubricate the pump, and the wear is very small. Sealing between rotating parts and fixtures can be accomplished directly by water seal.

5. Inhalation uniformity, stable and reliable work, simple operation, easy maintenance.

water ring vacuum pump shortcomings :

1. Low efficiency, generally around 30%, better up to 50%.

2. The low vacuum is not only limited by the structure, but also by the saturated vapor pressure of the working fluid. Using water as working fluid, the limit pressure can only reach 2000-4000Pa.

water ring vacuum pump energy saving:

1. The higher the temperature, the larger the volume of the gas. When the vacuum pump reaches the same vacuum degree, the suction flow will also rise, which will lead to the increase of load and energy consumption. Therefore, it is very important to control the temperature of circulating white water in summer, which requires the cooling system to maintain a good cooling effect. It is generally believed that recycled white water is best not to exceed 35 degrees Celsius. If the temperature is too high in summer, the cooling water flow can be increased appropriately, but at the same time, it should be noted that the excessive cooling water flow can also increase energy consumption, so the cooling water flow should be reduced appropriately in winter.

2. If the capacity of the vacuum pump obviously exceeds the demand of the vacuum system, there will be excess vacuum, which will result in waste of the effective pumping efficiency of the pump. By adjusting the frequency of the frequency converter through PID control, the effective pumping rate of the mechanical pump can be adjusted, and the purpose of energy saving and consumption reduction can be achieved.

3. When the motor speed is fixed and the water level is within a certain range, the water ring formed by the high water level is large and the water ring formed by the low water level is small. That is to say, when the water ring is larger, the power consumption will increase, so the efficiency of the water ring vacuum pump will decrease and the power loss will increase. Regular monitoring of the surface vacuum value of the water-loop pump and human intervention in the water supply can ensure the maximum efficiency of the vacuum pump (can also be made into PID adjustment).

4. Internal wear: After 3-5 years of operation, because of the wear of the rotor and distribution plate, the clearance between the rotor and the pump shell increases, and the vacuum will leak, which will result in the decrease of the suction capacity. It is necessary to arrange for the repair or replacement of the rotor and distribution plate, so as to prevent the increase of energy consumption caused by the decrease of the vacuum suction capacity.

water ring vacuum pumps operating problems :

1. In the paper industry, the working medium of vacuum pump (i.e. supplementary liquid) is mainly clear water or white water. Northern clean water usually has high hardness, while the metal ions in white water are complex, so the internal parts of vacuum pump will form scales after a long physical and chemical process. The scaling problem of vacuum pump can be solved by series washing. After the vacuum system is completely cleaned and replaced with clean water, 5% dilute hydrochloric acid and appropriate system cleaning agent are added. The temperature is maintained at 45-50 C. After 2 hours of circulation, water series washing can be added. The cleaning cycle is usually 3 months. At the same time, the scale inhibitor can be used for a long time to keep the impeller clean and the whole vacuum circulation system clean.

2. Vibration problems often occur in water-loop vacuum pumps. Fracture of valve plates, scaling of rotor blades, damage of rubber pad of coupling, large change of water ring and other problems may lead to vibration. During the downtime, the above problems need to be checked one by one to ensure that abnormal problems are found and solved in advance.

3. The impeller of a water ring vacuum pump may vaporize when the pressure in the local area of the pump falls below the saturated vapor pressure of the corresponding temperature of the liquid, resulting in bubbles which will eventually cause high frequency water hammer; or because of misoperation, suddenly close or open the valve, resulting in a sudden change in the flow velocity of the liquid, resulting in repeated and sharp changes in the direction and size of the pressure in the pipeline. Water hammer phenomenon occurs and metal surface is damaged.

Measures to prevent impeller cavitation:

(1) Increase the flow area at the suction port of the pump, reduce the flow rate and increase the pressure of the suction port.

(2) Maintain the reasonable water level of the steam-water separator (300 m below the full water level), avoid the blockage of the heat exchanger, and ensure the appropriate height of the liquid level of the vacuum pump.

(3) To shorten the length of suction pipe of vacuum pump as far as possible, reduce unnecessary pipe fittings, and make the center line of pump as close as possible to the liquid level of steam-water separator. When sucking saturated water, the negative installation height should be taken as far as possible to maximize the injection height to improve the suction performance of the pump.

(4) Using anti-cavitation materials. When the operating conditions of the pump are limited and it is impossible to avoid cavitation completely, the impeller should be manufactured with good anti-cavitation materials (such as 2Cr13, copper-based alloy, etc.) or sprayed on the surface of the pump shell and impeller runner to prolong the service life of the impeller.

(5) After the occurrence of cavitation, the pump must be stopped and the impeller must be repaired in time to coat with anticorrosive materials.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)