What is a vacuum pump

Vacuum pump refers to the device or equipment that obtains vacuum by mechanical, physical, chemical or physical chemical methods. Generally speaking, vacuum pump is a device that improves, generates and maintains vacuum in a closed space by various methods.

With the development of vacuum application, many kinds of vacuum pumps have been developed. Their pumping speed has risen from zero to hundreds of thousands and millions of liters per second. With the application of vacuum technology in the field of production and scientific research, the pressure range of vacuum technology is becoming wider and wider. Most vacuum pumps need to be composed of several vacuum pumps to suck together before they can meet the requirements of production and scientific research. Because the working pressure range of vacuum application department is very wide, any type of vacuum pump can not be fully applied. All working pressure ranges can only use different types of vacuum pumps according to different working pressure ranges and different working requirements. In order to use conveniently and meet the needs of various vacuum process, sometimes all kinds of vacuum pumps are combined according to their performance requirements for unit type application.

Common vacuum pumps include dry screw vacuum pump, water ring pump, reciprocating pump, slide valve pump, rotary vane pump, Roots pump and diffusion pump. These pumps are indispensable main pumps in the application of vacuum technology in various industries of national economy. In recent years, with the sustained and high-speed development of China’s economy, the downstream application industry of vacuum pumps has maintained a rapid growth momentum. At the same time, the vacuum pump industry in China has achieved sustained, stable and rapid development driven by the constant expansion of the application field of vacuum pumps and other factors.

(1) pump general structure:

The layout structure of the pump body of the vacuum pump determines the overall structure of the pump.

Vertical structure of the intake and exhaust port level settings, assembly and connection pipelines are more convenient. But the center of gravity of the pump is high and its stability is poor at high speed, so this type of pump is mostly used in small pumps.

Horizontal pump intake is in the upper, exhaust is in the lower. Sometimes in order to facilitate the installation and connection of the vacuum system pipeline, the exhaust outlet can be connected from the horizontal direction, that is, the direction of intake and exhaust is mutually perpendicular. At this time, the exhaust outlet can be opened in both left and right directions. In addition to one end of the exhaust pipe, the other end is blocked or connected with a bypass valve. The pump has low center of gravity and good stability at high speed. Generally large and medium-sized pumps use this structure.

The two rotor shafts of the pump are installed vertically with the horizontal plane. The assembly clearance of the structure is easy to control, the assembly of the rotor is convenient, and the area of the pump is small. But the center of gravity of the pump is high and the gear disassembly and assembly is inconvenient, and the lubrication mechanism is relatively complex.

(2) pump driving mode:

The two rotors of the vacuum pump operate relatively synchronously through a pair of high precision gears. The drive shaft is connected with the motor through a coupling. There are two main types of transmission structure arrangement: one is that the motor and the gear are placed on the same side of the rotor as shown in the figure. The driven rotor is driven directly by the end gear of the motor, so that the torsional deformation of the active rotor shaft is small, and the clearance between the two rotors will not change because of the torsional deformation of the active shaft, so that the clearance between the rotors is uniform in the course of operation. The biggest disadvantage of this transmission mode is: a. There are three bearings on the drive shaft, which increases the difficulty of processing and assembling the pump, and the disassembly and adjustment of the gears are inconvenient; B. The overall structure is not symmetrical, and the center of gravity of the pump is biased to the side of the motor and gear box.

Vacuum pump characteristics:

(1) There is a large pumping speed in a wide pressure range;

(2) The rotor has good geometric symmetry, so it has small vibration and smooth operation. There are clearances between the rotors and between the rotors and the housing. Without lubrication, the friction loss is small, which can greatly reduce the driving power and achieve higher speed.

(3) There is no need for oil seal and lubrication in the pump chamber, which can reduce the pollution of oil vapor to the vacuum system.

(4) There is no compression and exhaust valve in the pump chamber. Its structure is simple and compact, and it is insensitive to dust and water vapor in the exhausted gas.

(5) Compression ratio is low and the effect of hydrogen extraction is poor.

(6) The surface of the rotor is a curved cylindrical surface with complex shape, so it is difficult to process and inspect.

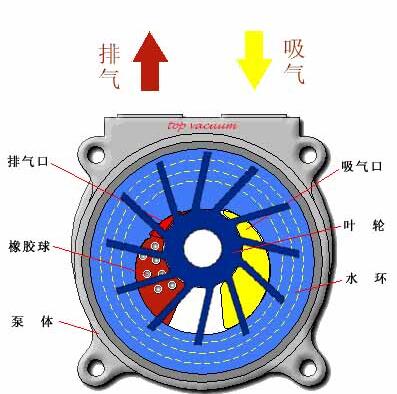

1. Water Ring Vacuum Pump Working Principle:

The impeller of the blade of the water ring vacuum pump is eccentrically installed in the cylindrical pump shell. A certain amount of water is injected into the pump. When the impeller rotates, the water is thrown to the pump shell to form a water ring whose inner surface is tangent to the hub of the impeller. Because the pump shell and impeller are not centrifugal, the intake space 4 between the right hub and the water ring gradually expands, thus forming a vacuum, so that the gas enters the intake space of the pump through the intake pipe. Then the gas enters the left half. As the volume between the hub rings is gradually compressed and the pressure is increased, the gas is discharged to the pump through the exhaust space and exhaust pipe.

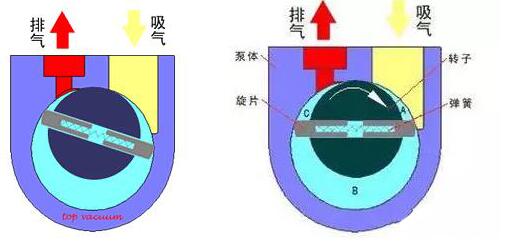

2.rotary vane vacuum pump working principle:

Rotary vane vacuum pump (Rotary vane pump) is an oil-sealed mechanical vacuum pump. Its working pressure ranges from 101 325 to 1.33 x 10-2 (pa) and belongs to low vacuum pump. It can be used alone or as the front pump of other high vacuum pumps or ultra-high vacuum pumps. It has been widely used in metallurgy, machinery, military industry, electronics, chemical industry, light industry, petroleum, medicine and other production and scientific research departments.

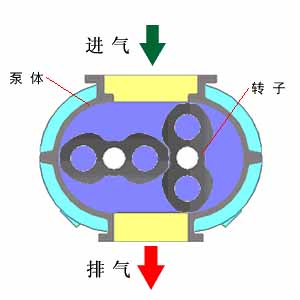

3. Roots Vacuum Pump Working Principle :

The working principle of Roots pump is similar to that of Roots blower. Because of the continuous rotation of the rotor, the exhausted gas is sucked into the space between the rotor and the pump shell from the intake port, and then discharged through the exhaust port. Because the space of V0 is completely closed after inhalation, there is no compression and expansion of gas in the pump chamber. But when the top of the rotor rotates around the edge of the exhaust port and the space of V0 is connected with the exhaust side, because the pressure of the exhaust side is high, some of the gas rushes back into the space of v0, which makes the pressure of the gas suddenly increase. When the rotor continues to rotate, the gas is discharged out of the pump.

The quality of vacuum pump depends on its mechanical structure and oil quality. It must be well protected when using vacuum pump. If the volatile organic solvents are distilled, the organic solvents will be absorbed by the oil and the vapor pressure will be increased, thus reducing the pumping efficiency. If it is acid gas, it will corrode the oil pump. If it is water vapor, it will make the oil into emulsion and destroy the vacuum pump.

Therefore, the following points should be paid attention to when using vacuum pumps:

Absorption devices must be installed between the distillation system and the vacuum pump.

Before distillation, the vapor of organic solvent in the system must be thoroughly pumped out by water pump.

If pumps can be used to pump air, then try to use water pumps, such as distilled substances containing volatile substances, you can first use water pumps to reduce pressure, and then use oil pumps.

The decompression system must be airtight, all rubber plugs should be of appropriate size and aperture, and rubber pipes should be vacuum rubber pipes. The ground glass is coated with vacuum grease.

Vacuum pumps can be classified into three categories according to their range of use and pumping efficiency.

(1) General pumps, pressure can reach 1.333-100kPa (10-760mmHg) for “rough” vacuum.

(2) Oil pump, the pressure can reach 0.133-133.3Pa (0.001-1 mmHg) for the “sub-high” vacuum.

(3) Diffusion pump, the pressure can reach below 0.133 3a, (10-3 mmHg) is a “high” vacuum.

If you want lower pressure, you need to use oil pumps, good pumps can pump up to 133.3a (1mmHg).

There are two kinds of vacuum pumps commonly used in organic chemistry laboratories: water pump and vacuum pump. If the pressure is not very low, the pump can be used. If the pump is well constructed and the water pressure is high, the pumping efficiency can reach 106 7-3333 Pa (8-25 mmHg). The minimum pressure pumped by the pump is theoretically equivalent to the vapor pressure at the water temperature at that time. For example, when the water temperature is 25, 20 and 10, the pressure of water vapor is 3192, 2394 and 1197 Pa (8-25 mmHg), respectively. When pumping, safety bottles should be installed in front of the pump to reduce the water pressure and reverse the water flow. Before stopping pumping, the pump should be deflated first and then shut down.

Vacuum pump lubricant

In vacuum pumps, vacuum pump oil not only acts as a medium to obtain vacuum, but also lubricates, cools and seals mechanical friction points.

This is the most important performance of vacuum pump oil. Because of the high vacuum requirement of vacuum pump, paraffin-based narrow fraction lubricant is generally used. For diffusion vacuum pump, silicone oil or other synthetic oil with low vapor pressure can also be used.

As the volume of the vacuum pump chamber changes continuously, the exhaust effect is formed. It is required that the lubricating oil should have proper viscosity and viscous-temperature characteristics.

Vacuum pumps are developing at a high speed. Because of the high-speed friction between slider and pump body, oil is easy to oxidize and decompose. Especially, diffusion pumps often work in a high temperature environment, which makes the vapor pressure in the system increase and the vacuum degree decrease. Therefore, the vacuum pump oil is required to have good thermal oxidation stability.

If the vacuum pump inhales corrosive gas, it will react with the oil and corrode the parts of the pump. Inhaled air often contains water vapor condensate, which causes the emulsification of the vacuum pump oil and metal corrosion, so good corrosion resistance and emulsification resistance are required.

In order to avoid affecting the saturated vapor pressure of oil products, the vacuum pump should not carry light components.

Limit pressure is an important performance index of vacuum pump oil to understand the limit pressure of vacuum pump under the lowest vacuum limit pressure.

High Temperature of Vacuum Pump Motor

A company’s 300 MW units, each unit equipped with two mechanical vacuum pumps, one of which operates, one standby. Vacuum pump is used to vacuum the unit at start-up and to extract the unconsolidated gas in condenser at normal operation. The pump is equipped with motor 160kW, speed 590r/min, rated current 330 A, voltage 380V, B insulation, and current 220-230A in normal operation. Every summer, the motor temperature will exceed the limit, forced to install temporary cooling fan, but the effect is not good. Long-term high temperature operation of motor will cause insulation aging and shorten its service life. The reasons for the high temperature of vacuum pump motor are analyzed as follows.

Cause analysis

(1) The motor has high power, high working current and high calorific value.

(2) The fan has low speed, low air pressure and low air volume.

(3) The number of fan blades is small, and the amount of wind generated is small.

(4) Dust and oil are attached to the motor, which reduces the heat dissipation capacity.

(5) The bus voltage of the vacuum pump motor is 380V. Because of the uneven voltage drop and load distribution of the cable, the actual voltage applied by the motor is only 365V. The low voltage results in a large operating current.

countermeasure

The power and speed of the motor are matched with the vacuum pump and can not be changed. The fan is installed on the main shaft of the motor, and the speed of the motor determines the speed of the fan, which can not be replaced. Increasing the number of fan blades can play a role, but when the number of blades increases, the dynamic balance is not easy to find. If the corrections are not good, the vibration of the motor will increase.

(1) The original fan cover is lengthened by 40 cm, and an axial fan with the same diameter as the fan cover is installed inside. The motor power of the axial fan is 850W, the speed is 1489r/min, and the voltage is 380V. The original fan remains. There is another power supply control for the axial fan, and there is no linkage between the axial fan and the main motor. After the start of the vacuum pump, the axial fan is started in time, and the axial fan is stopped 30 minutes after the shutdown of the vacuum pump, so that the main motor can be fully cooled.

(2) Clean up the dust on the motor regularly, keep the motor radiator clean and increase its heat dissipation capacity;

(3) The bus voltage of the vacuum pump is adjusted to 400 V.

Effect

(1) The cooling effect is greatly enhanced due to the high speed of the axial flow fan and the large air pressure and volume. Under the same ambient temperature and load current, the temperature of the main motor decreases by 12 degrees. The temperature of the main motor in summer has not exceeded the limit.

(2) The axial-flow fan can be controlled artificially. After the main motor is out of operation, the axial-flow fan can still operate, which can make the main motor fully cooled.

(3) Make the load distribution of the two buses balanced as far as possible, so as to prevent the voltage of a bus from falling too much because of the overload.

(4) After voltage adjustment, the operating current of the vacuum pump drops to 210A, and the calorific value decreases relatively.

(5) The insulation aging speed of the main motor is slowed down and its service life is prolonged.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)