What is pneumatic vacuum ball valve

Our pneumatic ball valve is specially designed and meticulously manufactured on the basis of the introduction of foreign advanced technology. Matched with electric valve positioner, input 4-20madc signal and 0.5-0.7mpa gas source to control operation and realize the adjustment of pressure, flow, temperature, liquid level and other parameters.

It is driven by compressed air, and the valve stem drives the valve core to rotate 90 ° in the valve body, which can realize the action of full open and full close. The product is divided into metal seal and soft seal according to its sealing performance. Guq series vacuum (pressure) ball valve is suitable for connecting or cutting off the medium flow of pipeline in vacuum system. The valve is a straight through ball valve, sealed by spherical surface, so it can be used not only in vacuum state, but also in low pressure state, and can be installed at any position.

Guq pneumatic vacuum ball valve drives the ball valve by changing the direction of the air circuit through the electromagnetic directional valve and controlling the executive cylinder to connect or cut off the medium flow in the vacuum (pressure) system pipeline.

The applicable working medium is acid and alkaline gas or liquid, which is used in vacuum, dairy products, wine industry, bioengineering, food, pharmacy, beverage, cosmetics and chemical industry. Optional feedback signal device and electric valve positioner.

pneumatic vacuum ball valve features:

1. It adopts 1 / 4 rotary pneumatic or electric actuator, which works stably. The valve switch has electric signal output and can be used for both hand and electricity.

2. Not only the structure is simple, the sealing is good, but also the installation size is small, the driving torque is small, the operation is simple, and it is easy to realize quick opening and closing

3. It can be used in high vacuum or low-pressure system to achieve the advantages of both positive and negative pressure

pneumatic vacuum ball valve working principle and structure:

Pneumatic ball valve is composed of pneumatic piston actuator and o-ball valve.

At (GT) series pneumatic actuators are double acting and single acting (spring return) with the same specification; the standard rotating shaft angle can be adjusted from – 5 to + 50; all sliding parts adopt plastic bearing bush and guide to maintain the minimum friction and effectively resist wear; the shell surface is anodized and electroplated to prevent corrosion; the rotating shaft is coated with hard nickel phosphorus alloy; screws The nut is made of stainless steel; the single acting spring is preassembled in the spring seat, which is easy to assemble or supplement the spring quantity; the connection and installation interface are designed with standardized module, which is convenient to assemble ball valve, signal box and control accessories; the rotation direction can be selected to rotate clockwise or anticlockwise; the two end adjusting screws can be adjusted less than the calibration angle. Stainless steel shell can be used in special corrosive environment.

The floating ball valve adopts a special design of double bevel elastic sealing ring, which effectively reduces the friction between the ball and the sealing ring and reduces the operating torque. When the medium pressure is small, the angle area between the seal ring and the ball is small, so there is a large sealing pressure ratio to ensure reliable sealing. When the medium force is large, the area of the seal ring and the sphere also increases. Therefore, the sealing ring can bear a large medium thrust without damage, so as to ensure reliable sealing. When the scour force of the medium is large, the specially designed valve seat anti scour structure can effectively prevent the scour of the medium and ensure the service life of the sealing ring. For the ball valve used in low pressure, ultra-low pressure or vacuum conditions, because the pressure of the medium itself can not ensure the reliable sealing of the valve seat, and the preload will decay after long-term use. The specially designed spring loaded sealing structure can ensure the long-term reliable use of the valve.

Material of main parts

Valve body, bonnet and stem: stainless steel

Seals: Teflon, NBR, Viton, ppl.

Actuator and accessories

Can be equipped with actuator – GTD / GTE series, at series, AW series.

Accessories available – solenoid valve, travel switch, air filter pressure reducer, electric / pneumatic valve positioner, handwheel, etc.

pneumatic vacuum ball valve main technical data :

|

applicability(Pa) |

Quick release flange(KF)2×105 ~1.3×10-6 |

| looper flange 6×105 ~1.3×10-6 | |

| Valve leak rate(Pa.L/S) | ≤1.3×10-6 |

| Applicable temperature(℃) | Standard delivery:-30~+150 |

| Special designation:-30~+240 | |

| Air source pressure(MPa) | 0.4~0.8 |

| Flange standard | GB4982;GB/T6070 |

| Installation position | arbitrarily |

| supply voltage | Standard delivery:AC220V/50Hz |

| Special designation:①AC110V;②DC24V;③DC12V | |

| signal feedback | Standard delivery:Valve position indicator |

| Special designation:① Microswitch ② intelligent 4 ~ 20mA DC ③ explosion proof microswitch | |

| Cylinder Optional | Standard delivery:Double acting |

| Special designation:Single acting (with spring return) available in N.O. or N.C |

pneumatic vacuum ball valve boundary dimension and connection dimension (mm):

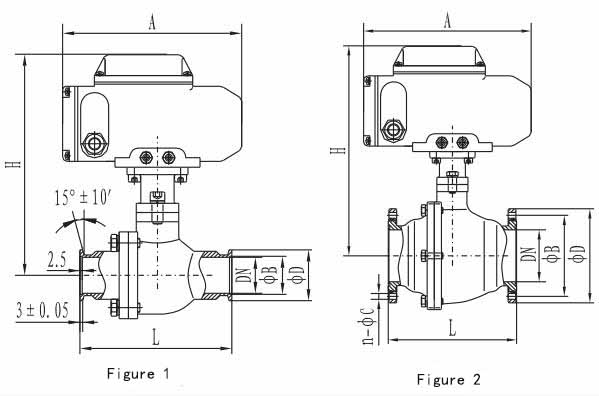

Figure 1 quick release flange (KF) connection and boundary dimension (gb4982)

| model | Drift diameter(DN) | ΦD | ΦB | H | L | A |

| GUQ-10/KF | 10 | 30 | 12.2 | 160 | 92 | 146 |

| GUQ-16/KF | 16 | 30 | 17.2 | 162 | 100 | 146 |

| GUQ-25/KF | 25 | 40 | 26.2 | 191 | 114 | 168 |

| GUQ-40/KF | 40 | 55 | 41.2 | 267 | 165 | 260 |

| GUQ-50/KF | 50 | 75 | 52.2 | 289 | 175 | 268 |

Figure 2 looper flange connection and boundary dimension (GB / t6070)

| model | Drift diameter(DN) | ΦD | ΦB | H | L | A | n-ΦC |

| GUQ-10 | 10 | 50 | 40 | 160 | 92 | 146 | 4-Φ6.5 |

| GUQ-16 | 16 | 60 | 45 | 162 | 100 | 146 | |

| GUQ-20 | 20 | 65 | 50 | 191 | 114 | 168 | |

| GUQ-25 | 25 | 70 | 55 | 191 | 114 | 168 | |

| GUQ-32 | 32 | 90 | 70 | 230 | 140 | 204 | 4-Φ9 |

| GUQ-40 | 40 | 100 | 80 | 267 | 165 | 260 | |

| GUQ-50 | 50 | 110 | 90 | 289 | 175 | 268 | |

| GUQ-63 | 63 | 130 | 110 | 313 | 186 | 268 | |

| GUQ-80 | 80 | 145 | 125 | 346 | 198 | 298 | 8-Φ9 |

| GUQ-100 | 100 | 165 | 145 | 375 | 220 | 298 | |

| GUQ-125 | 125 | 200 | 175 | 444 | 266 | 458 | 8-Φ11 |

| GUQ-150 | 150 | 225 | 200 | 497 | 296 | 525 | |

| GUQ-200 | 200 | 285 | 260 | 620 | 390 | 602 | 12-Φ12 |