What kind of vacuum pump is used in the suction machine?

Plastic absorber (also known as thermoplastic moulding machine) is a machine that absorbs thermoplastic coils such as PVC, PE, PP, PET, HIPS and so on, which are heated and plasticized, into advanced packaging boxes, frames and other products of various shapes. By using the vacuum suction produced by vacuum pump, the heated and softened thermoplastic sheets such as PVC, PET and so on were absorbed into various shapes of vacuum cover, absorbent tray and bubble shell through the mould.

Vacuum equipment

Vacuum system consists of vacuum pump, gas storage tank, valve, pipeline and vacuum meter. A single type vacuum pump is often used in vacuum forming. The vacuum degree of this pump should be above 0.07-0.09 Mpa (520 mmHg). Gas storage tanks are generally cylindrical boxes welded with thin steel plates, with oval bottoms. The capacity of the gas storage tank should be at least half that of the maximum forming chamber. The vacuum pipeline must be equipped with appropriate valves to control the narrow vacuum capacity.

The rotating power of the vacuum pump is determined by the size and speed of the forming equipment. The equipment with larger or faster forming speed is usually used up to 2-4KW. The size of the vacuum central system depends on the specific production and development requirements of the factory.

Vacuum Pump for Plastic Absorbing Machine Selection

Vacuum pumps are widely used in plastic suction machines. In humid weather in the south, the materials used for plastic suction will evaporate after heating, which requires that the vacuum pumps have the function of dewatering.

1. When choosing vacuum pump for plastic suction machine, it is necessary to select vacuum pump according to specific technology. The following two main parameters are used as reference:

2. Vacuum degree: The so-called vacuum degree is an expression of air rarefaction, usually expressed in Pa, Mba, mmHg and other units.

3. After the forming of the plastic-absorbing products, most of the bubbles are caused by the defect of the products because the vacuum degree can not meet the requirements. Compared with products with deep grooves, the vacuum requirement is higher.

4. Flow: refers to the amount of fluid pumped by a vacuum pump through a closed pipe or an effective cut-off body in a unit time. M3/H, L/S and L/Min are commonly used to express

5. Vacuum flow is an important indicator of suction. When choosing a vacuum pump, we should pay attention to the specifications and thickness of the product to calculate how much air it needs to be pumped out in an hour or a minute, so as to determine how much flow is required. Vacuum pump.

The SV rotary vane vacuum pump of EVP Vacuum Co., Ltd. belongs to the rotary vane vacuum pump. It is the most suitable vacuum pump for the use of plastic suction machine and the best sold vacuum pump product in China.

SV rotary vane vacuum pump is a single-stage rotary vane mechanical vacuum pump. It has simple structure, easy operation and convenient maintenance. It is a basic equipment for obtaining vacuum in a wide range of applications. Its working principle is the same as that of general volume pump. It consists of a rotor installed concentrically with drive shaft and in eccentric position in the pump body. There are three radial sliding blades on the rotor. The pump chamber is divided into three chambers, and the pump chamber is entered by the suction port. The pump chamber is entered through the open backstop valve and filter screen. When the rotor rotates, the suction chamber is self-connected with the pump chamber. The intake is isolated and the gas is compressed and discharged through the passage between the pump chamber and the exhaust box. Rotate for one week and repeat three times.

Rotary vane vacuum pump display picture

Technical parameter

| Model | Pump speed(m3/h) | Motor Power(KW) | Inlet Diam (inch) | Rotary speed(rpm) | Oil Capacity(L) | G.W(kg) | NoisedB (A) | Dimensions(mm) | |

| 50HZ | 60HZ | ||||||||

| SV-010 | 10 | 12 | 0.37 (3ph)0.55 (1ph) | G1/2 | 1400 | 0.5 | 20 | 64 | 405*253*210 |

| SV-020 | 20 | 24 | 0.75 (3ph)0.90 (1ph) | G1/2 | 2800 | 0.5 | 20 | 64 | 405*253*210 |

| SV-025 | 25 | 30 | 0.75 (3ph)0.90 (1ph) | G1/2 | 2800 | 0.5 | 22 | 64 | 405*253*210 |

| SV-040 | 40 | 48 | 1.5 (3ph)2.2 (1ph) | G11/4 | 1400 | 1.0 | 50 | 67 | 660*300*270 |

| SV-063 | 63 | 75 | 2.2 | G11/4 | 1400 | 2.0 | 83 | 68 | 695*420*295 |

| SV-100 | 100 | 120 | 3.0 | G11/4 | 1400 | 2.0 | 87 | 72 | 735*420*295 |

| SV-160 | 160 | 192 | 4.0 | G2 | 1400 | 4.5 | 152 | 74 | 805*520*410 |

| SV-200 | 200 | 240 | 5.5 | G2 | 1400 | 4.5 | 159 | 76 | 825*520*410 |

| SV-250 | 250 | 300 | 7.5 | G2 | 1400 | 7.0 | 230 | 76 | 1000*550*410 |

| SV-300 | 300 | 360 | 7.5 | G2 | 1400 | 7.0 | 236 | 76 | 1200*550*410 |

| SV-630 | 630 | 750 | 15.0 | DN100 | 960 | 35 | 620 | 75 | 1630*1300*980 |

| SV-750 | 750 | 900 | 18.5 | DN100 | 1150 | 35 | 640 | 76 | 1630*1300*980 |

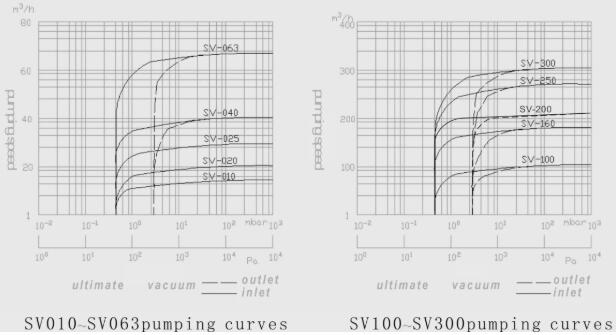

Performance curve

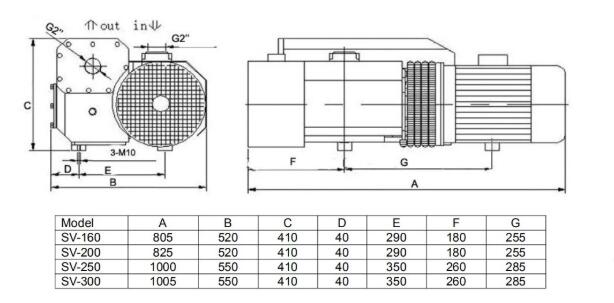

Installation dimension

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)