Why vacuum coating should be coated under vacuum conditions?

When they first learn about or come into contact with the vacuum coating machine industry, many people are curious as to why the evaporation vacuum coating equipment must evaporate materials in a vacuum state, and the vacuum plating must meet certain standards. I will introduce it to you in detail below:

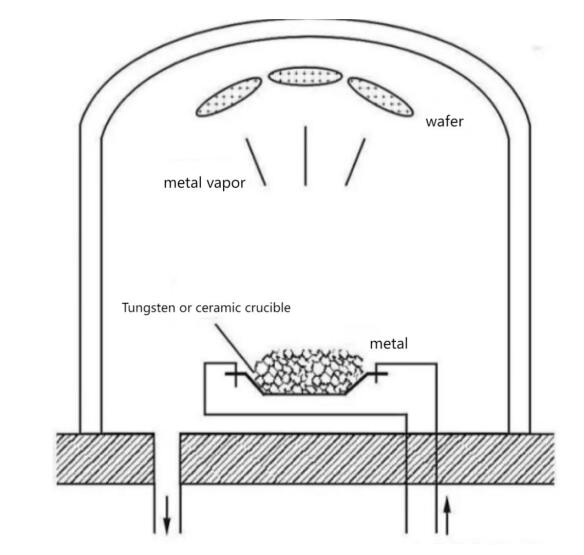

Since the pressure of a gas is proportional to the number of molecules per unit volume, the mean free path is also proportional to the pressure of the gas. In the process of vacuum deposition of thin films, when the deposition distance is greater than the mean free path of molecules, it is called low vacuum deposition, and when the deposition distance is smaller than the mean free path of molecules, it is called high vacuum deposition.

During high vacuum deposition, the collision between evaporated atoms (or molecules) and residual gas molecules is negligible, so the vaporized atoms fly toward the substrate in a straight line, so that the vaporized atoms that maintain large kinetic energy and reach the substrate can be A stronger film layer is condensed on the substrate. During low-vacuum deposition, the speed and direction of vaporized atoms will change as a result of collisions, and aggregations of vapor atoms may even be generated in space – the principle is similar to the way water vapor generates fog in the atmosphere.

The pollution of residual gas can be reduced at a higher degree of vacuum. When the degree of vacuum is not too high, the vacuum chamber contains many residual gas molecules (oxygen, nitrogen, water and hydrocarbons, etc.), which can contribute to the coating of the film. brings great harm.

1.Their collision with the vaporized film material molecules shortens the mean free path (due to the thermal motion of gas molecules, collisions between molecules are also extremely frequent, so although the speed of movement of gas molecules is quite high (up to several seconds per second) 100 meters), but because it has to collide with other molecules many times in the process of moving forward, the distance traveled by a molecule between two consecutive collisions is called its free path, and the statistical average of the free path of a large number of molecules It is called the mean free path of the molecule.)

2.They collide with and react with the surface on which the film is forming.

3.They hide in the formed film and gradually erode the film.

4.They combine with the evaporation source at high temperatures to reduce their service life.

5.They form an oxide layer on the surface of the evaporated film material, making the evaporation process unable to proceed smoothly.

Therefore, when the evaporative vacuum coating machine is to deposit a film layer, the coating must be carried out in a vacuum state so that the film layer will be firm and free of contaminants.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)