2 Stage Side Channel Blower

The side-channel blower, whose impeller is mounted directly on the motor rotor, is completely contactless. Because the pump shaft is installed outside the compression chamber, so even if the work under the maximum pressure difference, also can ensure the maximum working reliability of the machine. Fan products is an important technology to provide gas in the industrial production of power equipment, services in the process, need to be in high temperature, corrosion, wear and so on all kinds of conveying gases under complicated environment, continuous operation cycle is long, the quality of product, high performance and reliability requirements, to the quality of the fan is good or bad will directly affect the industrial production safety. In such a big trend, the side channel blower industry’s prospects are bright. With the increasing demand, there are still some enterprises entering the side passage blower industry. Demand is now concentrated in Asia, North America and Europe.

Do you know the principle of side passage blower?

A machine that produces high pressure increments to the processed fluid. The blower consists of an impeller and in one of the peripheral annular channels is accommodated in the housing. During use, the impeller works without contact with surrounding parts, eliminating all lubrication-related problems and wear.

The side passage blower is suitable for different application areas and is designed to meet a variety of requirements for handling air, gas and liquid at pressure and compression. In addition to standard design blowers are specially configured for vertical or horizontal coupling and mechanical seals with double end faces; Energy-saving fan, explosion-proof fan installed in the potential explosion danger area.

In addition, all of our fans can be anodized with impregnation, seal, stainless steel bolts and screws and specially protected with corrosive gases

Two-stage side passage blower is used in waste water treatment system.

Aeration blowers provide high pressure and oxygen to bacteria to treat and stabilize waste water. Water aeration is the process of introducing air into a water body to increase its oxygen saturation. Oxygen is an important part of water quality and its ability to sustain life.

Most popular side passage blower models in water treatment plant:

| Product Model | Rated Power(Kw) | Max.Flow(m3/h) | Max.Vacuum mBar | Max.Pressure |

| LD 250 H43 RW9 | 25 | 2330 | -310 | 270 |

| LD 150 H43 RB9 | 1940 | -130 | 110 | |

| LD 165 H43 R29 | 16.5 | 1110 | -410 | 370 |

| LD 125 H43 R29 | 12.5 | 1110 | -300 | 370 |

| LD 110 H43 RB8 | 11 | 900 | -430 | 660 |

| LD 075 H43 RB8 | 15 | 900 | -200 | 180 |

| LD 150 H43 R28 | 15 | 520 | -460 | 670 |

| LD 110 H43 R28 | 11 | 520 | -430 | 600 |

| LD 075 H43 R28 | 7.5 | 520 | -400 | 400 |

| LD 075 H43 R27 | 7.5 | 320 | -440 | 570 |

| LD 055 H43 R27 | 5.5 | 320 | -440 | 500 |

| LD 043 H43 R27 | 4.3 | 320 | -360 | 380 |

| LD 030 H43 R27 | 3 | 320 | -280 | 260 |

| LD 022 H43 R27 | 2.2 | 320 | -220 | 210 |

| LD 040 H43 R25 | 4 | 230 | -390 | 490 |

| LD 030 H43 R25 | 3 | 230 | -340 | 410 |

| LD 022 H43 R24 | 2.2 | 150 | -330 | 440 |

| LD 016 H43 R24 | 1.6 | 150 | -280 | 280 |

| LD 008 H43 R23 | 0.85 | 110 | -200 | 230 |

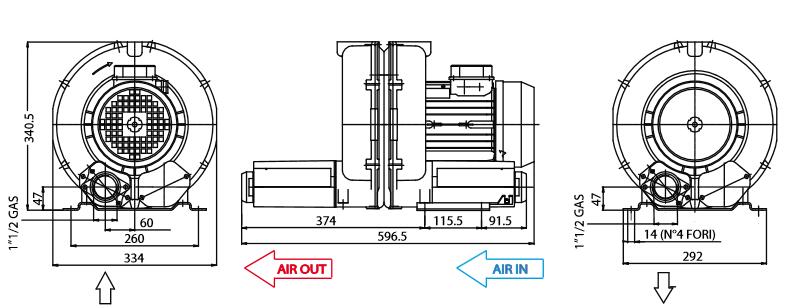

Dimensions: