2bv5-161 vacuum pump

2bv5-161 liquid ring vacuum pump supplier, hydraulic coupling is installed between pump and motor.

2bv5-161 vacuum pump, when the pump works under high pressure difference or starts at the same time with the front stage pump, there is a speed difference in the liquid coupling, that is, sliding, and only transmits a certain torque to slow down the pump.

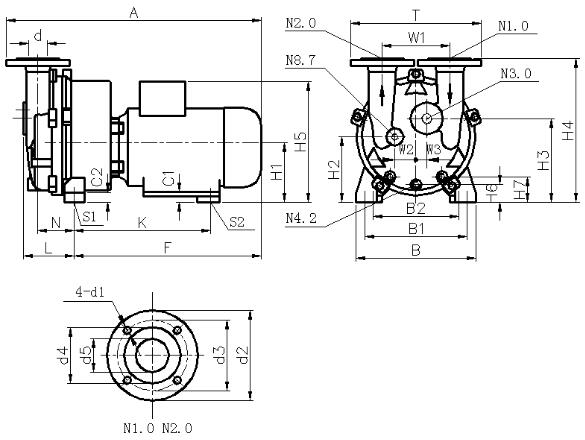

2BV5 liquid ring vacuum pump dimensions

| N1.0 suction port N2.0 vent |

N3.0 working fluid interface N4.2 drain |

N8.7 cavitation protection interface |

| model | A | B | B1 | B2 | C1 | C2 | H1 | H2 | H3 | H4 | H5 |

| 2BV5110 | 637 | 325 | 255 | 190 | 41 | 26 | 140 | 156 | 202 | 361 | 328 |

| 2BV5111 | 679 | 325 | 265 | 216 | 36 | 26 | 150 | 166 | 212 | 371 | 363 |

| 2BV5121 | 771 | 347 | 265 | 216 | 36 | 26 | 150 | 167 | 217 | 385 | 363 |

| 2BV5131 | 852 | 377 | 300 | 254 | 35 | 30 | 175 | 194 | 249 | 427 | 435 |

| 2BV5161 | 1044 | 479 | 370 | 279 | 30 | 30 | 210 | 225 | 303 | 521 | 485 |

| model | H6 | H7 | K | L | F | N | S1 | S2 | T | d1 | d2 |

| 2BV5110 | 38 | 57 | 342 | 130 | 464 | 92 | φ12 | φ12 | 340 | 19 | 160 |

| 2BV5111 | 48 | 68 | 348 | 130 | 500 | 92 | φ12 | φ12 | 340 | 19 | 160 |

| 2BV5121 | 39 | 60 | 430 | 147 | 584 | 97 | φ12 | φ12 | 381.5 | 19 | 182 |

| 2BV5131 | 53 | 76 | 477.5 | 147 | 658.5 | 103 | φ15 | φ15 | 381.5 | 19 | 182 |

| 2BV5161 | 51 | 80 | 565 | 201 | 808 | 138 | φ15 | φ15 | 450 | 22 | 200 |

| 型号 | d3 | d4 | d5 | W1 | W2 | W3 | d | N3.0 | N4.2 | N8.7 | |

| 2BV5110 | 123 | 97 | 52 | 180 | 52 | 27 | DN50 | G3/4″ | G3/8″ | G3/8″ | |

| 2BV5111 | 123 | 97 | 52 | 180 | 52 | 27 | DN50 | G3/4″ | G3/8″ | G3/8″ | |

| 2BV5121 | 142 | 113 | 66.5 | 200 | 57 | 29 | DN65 | G3/4″ | G3/8″ | G3/8″ | |

| 2BV5131 | 142 | 113 | 66.5 | 200 | 57 | 29 | DN65 | G3/4″ | G3/8″ | G3/8″ | |

| 2BV5161 | 156 | 130 | 80 | 250 | 81 | 41 | DN80 | G3/4″ | G3/8″ | G3/8″ |

It is often due to the abnormal operation of condensate pump or pump failure. At this time, the pump should be started and the fault pump should be stopped for maintenance. If the hardness of condensate is large, it can be judged that the leakage of condenser copper pipe is caused. In addition, improper operation of condensate recycling is also the cause of this fault. Therefore, attention should be paid to this point in the use of liquid ring vacuum pump.

Whether it is reciprocating vacuum pump or any other vacuum pump equipment, there are very strict requirements in mechanical seal.

We usually use mechanical floating ball control valve, one to control water inflow and the other to control drainage, so as to keep the water level in a certain range. The extracted gas contains steam, which may condense into water to increase the water level and increase the motor power; however, it is more likely that the pump performance will drop sharply due to the water level drop or even no water, which will lead to the change of condenser pressure and affect the efficiency of generator set. The large pressure difference of reciprocating vacuum pump is determined by the large torque transmitted by the hydraulic coupling, and the large torque transmitted by the hydraulic coupling is adjusted by the amount of liquid in it.

The liquid level in the separator directly affects the performance of liquid ring vacuum pump.

With the pumping process, the gas load of 2bv5-161 vacuum pump decreases, and the vacuum pump gradually accelerates to the rated speed. The use of hydraulic coupling can also prevent the overload of the pump, so that the pump can work under high pressure difference.