Rotary vane vacuum pump

What is rotary vane vacuum pump:

Rotary vane vacuum pump is one of the main pumps for obtaining low and medium vacuum pumps. It can be divided into oil seal pump and dry pump. According to the required vacuum degree, single stage pumps and double stage pumps can be used, and the application of double stage pumps is more common.

Rotary vane vacuum pump is mainly composed of pump body (stator) and rotor. More than two pieces of rotary vane are installed in the rotor slot, and some springs are also installed between the rotary parts. The rotor is eccentrically installed in the pump cavity, and the clearance between the outer edge and the top surface of the pump cavity is 2~3 microns. When the rotor rotates, under the action of centrifugal force, the rotating blade slides along the groove and keeps contact with the inner wall of the pump chamber. The pump chamber is divided into two or several variable volume workshops. When the rotor rotates clockwise, the volume of the suction chamber connected with the suction port increases gradually from zero, and the pressure of the gas in the cavity decreases. The suction gas is continuously inhaled from the suction port. At the same time, the volume of the exhaust chamber connected with the exhaust port decreases from large to small, and the gas in the suction chamber is compressed. When the gas pressure is higher than the atmospheric pressure, the exhaust valve is pushed open to discharge the atmosphere. When the rotor rotates continuously, the pump will continuously exhaust.

2XZ Direct Drive Rotary Vane Vacuum Pump

Rotary vane vacuum pump working principle:

The working principle of rotary vane pump: rotary vane pump mainly consists of stator, rotor, rotary vane, fixed cover, spring and other parts. The structure uses the rotor which is eccentrically mounted in the stator cavity (the gap between the outer circle of the rotor and the inner surface of the stator is very small) and the two rotating blades which are close to the inner wall of the stator by means of spring tension and centrifugal force, sliding along the inner wall of the stator when the rotor rotates.

When the rotor rotates in the graphic direction, the volume of space A connected with the suction port increases continuously, and the pressure in space A decreases continuously. When the pressure in space A is lower than the pressure in the suction container, according to the gas The principle of pressure equilibrium is that the gas pumped is continuously pumped into the suction chamber A, which is in the process of inspiration. The volume of B cavity is decreasing and the pressure is increasing. When the pressure of the gas is stronger than the exhaust pressure, the compressed gas pushes the exhaust valve away, and the exhausted gas continuously passes through the oil layer in the tank and is discharged into the atmosphere. During the continuous operation of the pump, it continuously sucks. Gas, compression and exhaust process, so as to achieve continuous pumping purposes.

The exhaust valve is immersed in oil to prevent the air from flowing into the pump. The oil enters the pump cavity through the clearance, the oil hole and the exhaust valve on the pump body. All moving surfaces in the pump cavity are covered with oil, forming the seal between the suction cavity and the exhaust cavity. At the same time, the oil is filled with all harmful spaces to eliminate their influence on the limiting vacuum.

Rotary vane vacuum pump parameters:

| Models | 2XZ -2C | 2XZ-4C | 2XZ-6C | 2XZ-8C | 2XZ-15C | 2XZ-25C | ||

| Pump speed | 50HZ (L/s) | 2 | 4 | 6 | 8 | 15 | 25 | |

| 60HZ (L/s) | 2.4 | 4.8 | 7.2 | 9.6 | 18 | 30 | ||

| 50HZ (m3/h) | 7.2 | 14 | 22 | 29 | 54 | 90 | ||

| 60HZ (m3/h) | 8.6 | 17 | 25 | 35 | 65 | 108 | ||

| Ultimate pressure(Pa) | Partial pressure | 6×10ˉ² | 6×10ˉ² | 5×10ˉ² | 5×10ˉ² | 5×10ˉ² | 5×10ˉ² | |

| Total pressure | 1 | 1 | 1 | 1 | 1 | 1 | ||

| Rotary speed(r/min) | 50HZ | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | |

| 60HZ | 1720 | 1720 | 1720 | 1720 | 1720 | 1720 | ||

| Motor power(Kw) | 0.37 | 0.55 | 0.75 | 1.1 | 1.5 | 3.0 | ||

| Working voltage(v) | 220/380 | 220/380 | 380 | 380 | 380 | 380 | ||

| InletDiam(mm) | I.D. | KF-25 | KF-25 | KF-25 | KF-40 | KF-40 | KF-40 | |

| O.D. | ||||||||

| Dimensions(mm) | Length | 480 | 520 | 545 | 616 | 705 | 830 | |

| Width | 150 | 150 | 172 | 255 | 255 | 275 | ||

| Height | 200 | 200 | 285 | 360 | 360 | 440 | ||

| Noise(dBA) | 65 | 65 | 68 | 70 | 70 | 72 | ||

| Oil capacity (L) | 0.8 | 1 | 1.5 | 3 | 3.5 | 4 | ||

| G.W./N.W. (kg) | 22/20 | 26/22 | 55/46 | 70/60 | 86/75 | 105/85 | ||

Rotary vane vacuum pump features:

Rotary vane vacuum pump has the advantages of small volume, light weight, low noise and easy starting. In addition, there are measures to prevent oil return and no measures to prevent oil seal from polluting the site.

1. Rotary vane vacuum pump is the basic equipment to obtain vacuum. It can act independently. It can also be used as the pre-pump and pre-pump of various high vacuum systems to form Roots vane vacuum unit.

2. The air inlet of the rotary vane vacuum pump is continuously open to the atmosphere and can not run for more than three minutes.

3. Pumps are not suitable for the removal of corrosive to metal, chemical reaction to pump oil, containing particles of dust, to the body of excessive oxygen, explosive gas.

4. pump can be used as compression pump or delivery pump.

5. Working environment of rotary vane vacuum pump: the relative temperature is not more than 90% in the range of 5-40 C, and the inlet pressure is less than 13333Pa, which allows long-term continuous operation.

6. When installing and connecting the power supply, wiring according to the stipulation of the motor sign, attention should be paid to the direction of rotation of the motor and the direction of arrow on the support.

7. The diameter of the pipeline of the continuous pumped vessel shall not be less than the inlet diameter of the pump, and the pipeline shall be short and with few elbows, and the leakage of the pipeline shall be noted.

8. every time before starting to focus on oil level, to stop pump oil to oil glass diameter 4/5 height.

9. Use pump No. 1 or no. 100 vacuum pump oil with pump oil.

10. Rotary vane vacuum pump can start at once in the atmosphere or under any vacuum. If the single stage pump is difficult to start, the intake pipe plug cap can be switched off and then put into operation.

Rotary vane vacuum pump use:

1. before use, should carefully read the product manual, after opening the box should check the quality of shipment. Collect spare parts and technical documents, and remove exhaust protection. Installation, wiring and trial steering as required. The water pump is connected to the water.

2. In order to prevent fuel injection due to oil return and reversal, the opening of the pump should be opened first and the oil in the pump should be transferred to the tank by hand according to the regulations. At the same time, check the oil level, should be above the oil standard center, but do not fill the oil mark, more to be released.

3.auxiliary methods to judge turning. Put the sheath on the pump mouth, if it is sucked after pumping, it is forward and blown down, is the reverse. Normal voice is positive, abnormal voice is reverse.

4.if the valve is equipped with an inflatable solenoid valve at the pump port, it should be installed horizontally and simultaneously with the pump.

5. When the relative humidity is higher or the condensable steam such as water vapor can be extracted from the gas, the gas valve should be used.

6. According to the manual, vacuum pump oil is recommended. Note that ester vacuum pump oil can not be mixed with mineral oil vacuum pump oil and other oils, must be strictly cleaned before changing into ester vacuum pump oil.

7. Check the ultimate pressure of the pump with the compression mercury vacuum gauge as the criterion. The total pressure gauge should pay attention to the matching calibration and backup comparison regulation. It is suggested that a ball valve should be installed between the regulated and the tested pump. The time of regulation is extended when the valve is closed.

8.cleaning. It is not suitable to be washed, so that the free liquid enters the splice rotor and is not easy to discharge.

9.disassembly and assembly. In accordance with the instructions and regulations specified in the instructions, place them in good order and place them properly so as not to be wrong.

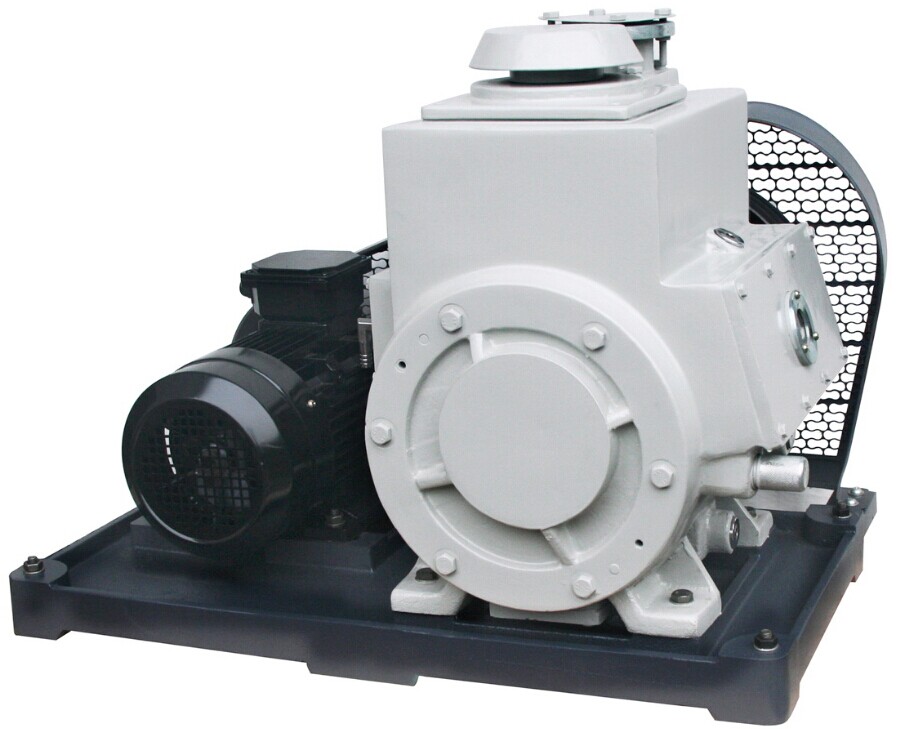

2X-A Rotary Vane Vacuum Pump

Rotary vane vacuum pump fault repair:

1.first of all, we need to know the type, characteristics and current situation of pumps. Understand usage requirements and determine repair objectives. Before the maintenance, prepare the testing means.

2.judge faults, diagnose faults. It is easy to judge correctly. Diagnosis should be verified.

3.troubleshooting, first and then complex, easy after the first difficult. No dismantling. To reduce the lack of dedicated tools and improper operation caused by new damage, reduce position changes and running time. Generally speaking, spliced rotor is not detachable, otherwise the shape and position tolerance will not be guaranteed, the rotor will be scrapped.

4. Poisonous and harmful, corrosive pumps, users should be asked to clean first, the necessary protection measures to protect the health of maintenance personnel.

Rotary vane vacuum pump fault classification:

1. it is recommended to divide failures into operational failures and performance failures.

2. operation faults can include pump not rotating, pump temperature too high, oil leakage, leakage, maximum power exceeding standard, etc.

3. Performance faults may include limit pressure, limit full pressure, pumping efficiency, noise, fuel injection, air ballast performance, etc. which are not up to standard or can not meet the requirements.

Rotary vane vacuum pump fault judgment:

1. pump does not turn: the situation is unclear, do not start the pump, so as not to aggravate the fault. Use your hands to move and not to move.

A. the pump can move without turning. The reason can be coupling failure, belt slip, motor wiring error, motor damage, power failure and so on.

B. Can’t move or coil up very heavy, the reason may be because the starting pump temperature is too low, pump oil viscosity is too high; design and manufacture reasons for shutting down too much oil. High oil level causes too much oil return (too much oil, or water vapor condensation in the pump, or condensation in the exhaust pipe in the pump); foreign bodies in the pump (welding slag in the intake pipe, oxide; scroll springs and other pump parts debris); scroll deformation seizure (copper sleeve, rotor, middle wall, pump cover, stator, stator, etc.); occurred. Bearing).

2. Pump Wen Taigao: the highest oil temperature measured near the lower exhaust valve exceeds the prescribed value of the instruction manual. As the pump temperature rises, the viscosity of the pump oil will be greatly reduced, and the saturated vapor pressure of the right pump oil will be increased, so that the pump’s limit pressure will be raised and the pumping efficiency will be reduced; rubber parts will be easy to aging; thermal expansion will make the reliability of operation. The reasons of too high pump temperature may be too high pump ambient temperature, too high intake temperature, intake cooling device failure, pump long-term continuous operation into the middle pressure is too high; water cooling pump cooling water is insufficient, circulating water design effect is not good; temperature control valve failure.

3. Oil leakage: It can occur in the seal of shaft seal, oil tank and pump parts, oil plug, oil mark, oil hole stuffy head, stator parts and support through-hole connection, air ballast valve (for example, 2X-8) and other parts. It can be caused by the aging of seals, improper installation, damage and failure, uneven surface, impurities, rough and loose castings. If the oil is stopped after the pump is stopped, the oil will enter the gas valve. If the valve is not closed, the valve may leak.

Self-made rubber pad, must use oil-resistant rubber, according to the original design shape, sealing surface is too big when pressure will leak oil.

4. Leakage: It can occur at water pipe head, water jacket sealing cover plane, drain hole plug, drain valve and other places, water jacket drilling, casting defects, freeze cracking, may also lead to leakage.

5. Maximum power exceeding standard: It can be caused by long-term continuous working inlet pressure too high, exhaust pressure too high, debris into the occurrence of occlusion, pump temperature too high, such as rotary blade clearance too small, too high voltage, pump fluid back into the pump too much, and so on, which will damage the motor. Try to avoid long-term continuous operation near the maximum power. If there are deposits on the surface, remove them regularly.

SV Rotary Vane Vacuum Pump

6. Limit pressure is not up to standard: it can be caused by leakage, internal leakage, blockage of oil holes, poor oil quality or pollution deterioration, water vapor and other condensable substances, instrument distortion, pump operation abnormal.

When the leakage is more, the exhaust port can see white steam. There are more bubbles at the oil mark, and the hand feels exhaust pressure on the exhaust port. There are more bubbles on the surface of the lower exhaust valve. The power will increase. At this time, the gas valve should be checked first. As the new pump factory each in the pump outlet limit pressure measurement, so if there is leakage, should be the pump outlet and pipelines, valves, containers one by one inspection. Failure of outer shaft seal, oil free oil cup and leakage of oil hole can also cause leakage. Internal leakage can be caused by wear, corrosion and occlusion caused by movement clearance, exhaust valve plane, exhaust valve sealing surface, inner shaft seal, pump cover plane, intake pipe, gas ballast valve seals and so on. When the oil hole is blocked, open the oil hole to listen, the noise of the pump will be lighter, in the case of well-sealed tank, if the hand in the exhaust port has the feeling of being absorbed, the exhaust valve may be invalid.

If the pump oil is clean and stored for a long time, it can be used to clean the water in the pump. If invalid, check the meter. If the pump oil yellowing and whitening has been emulsified, it can be completely opened to air town, adjust the air volume to purify the operation, if necessary, can be put into the pump outlet proper gas operation, can speed up the purification process. If you pump in other volatile gases or liquids, change the oil in time, and wash the oil tank if necessary. Some pumps, in the interstage airway will deposit pump fluid, in order to achieve good oil exchange effect, to try to deposit pump fluid discharge.

The limit pressure is measured by a block compression mercury vacuum gauge. With the calibrated thermocouple vacuum gauge and other manometer, the measured value will increase. Attention should be given to the calibration of thermocouple vacuum gauge. It is recommended that a calibrated regulator be prepared for the purpose of comparing the suspected pollution distortion.

The increase of ultimate pressure will reduce the pumping efficiency of high vacuum time and increase the ultimate total pressure. It can be judged, checked and handled by referring to the above description.

7. Noise: pump structure design, motor and pump bearing noise, rotating piece and other moving parts are smooth, too much oil, fan, transmission parts of the noise, large air intake, open air town operation, oil baffle and other pump parts loose, installation of unequal vibration, will affect the noise of the pump.

8. Fuel injection: The size, position and sealing condition of the oil return hole of the fuel tank for preventing fuel injection, the design and installation of the oil baffle, the mist reducer, the oil baffle cap and the oil-gas separator at the exhaust port, the oil level and the amount of oil in the inlet all affect the fuel injection of the pump. It can be as high as 30M / S. When the oil surface is blown open, the circulating oil in the pump and the oil brought out by the air flow will test the measures to prevent injection.

9. Others: Some pumps have oil pumps, oil separators, one-way valves on the oil road, mist eliminators, inlet filters (for oil steam reflux), dust filters and other components or accessories, but also to check. Oil pump failure will make the pump lubrication and seal failure, mist eliminator failure, it is possible to increase the exhaust pressure, increase the power, damage the motor, inlet filtration failure can increase the inlet resistance, reduce the pumping speed, reduce the efficiency of pumping.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)