Air blower for engraving machine

Air blower for engraving machine of selection

Those who are engaged in carving industry should be aware that there will be large dust or smoke in the process of carving. At this time, we need to use the blower to absorb the dust and transport it to another place. Then how to select the matching blower when using the engraving machine? Now let’s introduce it.

For example, in the jade carving operation, according to the survey data, the dust in the ventilation system of jade carving is hydrophilic. Two kinds of dust collectors are used

1. Impact water bath dust collector: the dust removal efficiency of 2,5,10 m particle size classification is 50.6%, 92.1%, 98.5%, and the total dust removal efficiency of dust containing air discharged from jade carving ventilation system is 97.0%. The dust concentration in the inlet air of the precipitator is 1000-2000mg / m3, which is 30-60mg / m3 after treatment, which can meet the requirements of the emission standard (150mg / m3). The resistance of the impinging water bath dust remover is about 1200 Pa. it can be built by itself. It has low initial investment and is easy to manage. It can treat the dust containing air of jade carving factory without producing sewage. When used in cold areas, the dust remover should be installed indoors. In winter, attention should be paid to antifreeze and the installation should ensure its tightness.

2. Bag filter: its dust removal efficiency can reach more than 98.0%, which can meet the requirements of emission standard, and the resistance is 1500-2500pa. Bag filter is easy to manage, but its initial investment and operation cost are high. In cold areas and places where it is inconvenient to use impact water bath dust collector, bag filter can be used for dust removal.

However, when jade carving is added with water, the humidity of the inhaled dust containing air is relatively high, which will make the dust adhere to the filter bag and is not easy to shake down.

Selection of blower: the fan shall ensure the air volume required by the ventilation and dust removal system and the total pressure required to overcome the maximum resistance pipeline of the system. The air volume of the fan is q = (1.10-1.15), and the total pressure of the fan is h = (1.10-1.15). The resistance of impact water bath dust collector is about 1200 PA and that of bag filter is 1500-2500 PA (when the moisture content in the air is large).

When the impact water bath dust collector is selected, the total pressure of the blower shall not be less than 2500pa. Generally, 2hb510 medium or 9-19 type blower (1450r / min) can be selected. When bag filter is selected for dust removal, the total pressure of the blower shall not be less than 3500pa, and 9-19 type blower (1450r / min) is generally selected. According to the air volume and total pressure provided by the blower, the required blower model is selected from the blower sample.

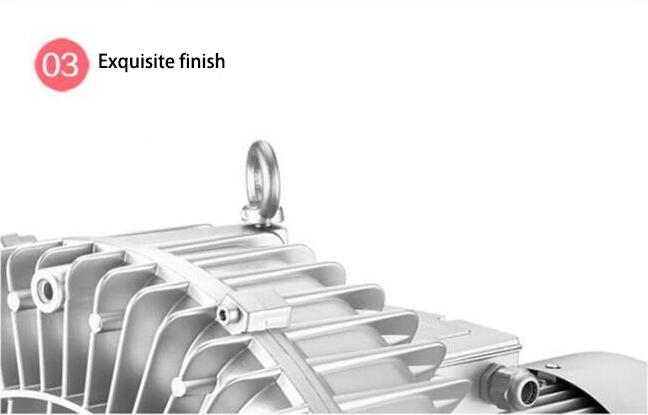

The real power faction, the details are not ambiguous.

The above information about the selection of blower for engraving machine is introduced.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)