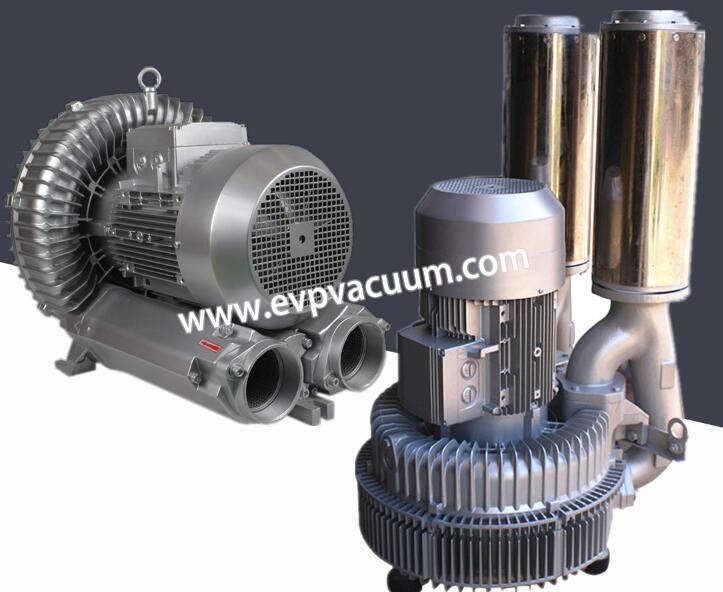

Air blower for grinding machine

Air blower of grinding machine of selection characteristics

1 in the selection of air blower before, should understand the domestic air blower production and product quality situation, such as the production of air blower varieties, specifications and the special use of various products, the development and promotion of new products, should also fully consider the requirements of environmental protection, in order to select the best blower.

2 in the air blower selection performance chart check there are more than two kinds of blower available to choose, should be preferred to choose the higher efficiency, smaller machine number: a larger adjustment range, of course, but also should be compared, weigh the advantages and disadvantages and decide.

3. If the diameter of the impeller of the selected blower is much larger than that of the original air blower, in order to make use of the original motor shaft, bearing and support, it is necessary to calculate the starting time of the motor, the strength of the original parts of the blower and the critical speed of the shaft.

4. When choosing centrifugal air blower, when the motor power equipped with it is less than or equal to 75KW, the valve can not be installed for starting only. When discharging high temperature flue gas or air and choosing centrifugal boiler blower, the valve should be set to start, in case of overload caused by cold operation.

5. For the ventilation system with noise elimination requirements, the air blower with high efficiency and low circumferential velocity of the impeller should be selected first and made to work at the highest efficiency point; Should also be according to the ventilation system to produce the noise and vibration mode of transmission, noise elimination and vibration reduction measures. The vibration reduction measures of blower and motor can generally be based on vibration reduction, such as spring shock absorber or rubber shock absorber.

6. In the selection of air blower, should try to avoid using the blower parallel or series work. When unavoidable, should choose the same type, with the performance of the blower joint work. When series is used, there should be certain pipe connection between the first stage blower and the second stage blower.

7. The selected new air blower should take full advantage of the original equipment, suitable for the site production and installation, safe operation and other issues.

The above is about sander air blower selection introduction finished!Air blower for grinding machine

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)